Page: 4-51

WALKER MANUFACTURING COMPANY

July 2006

SERVICE INSTRUCTIONS

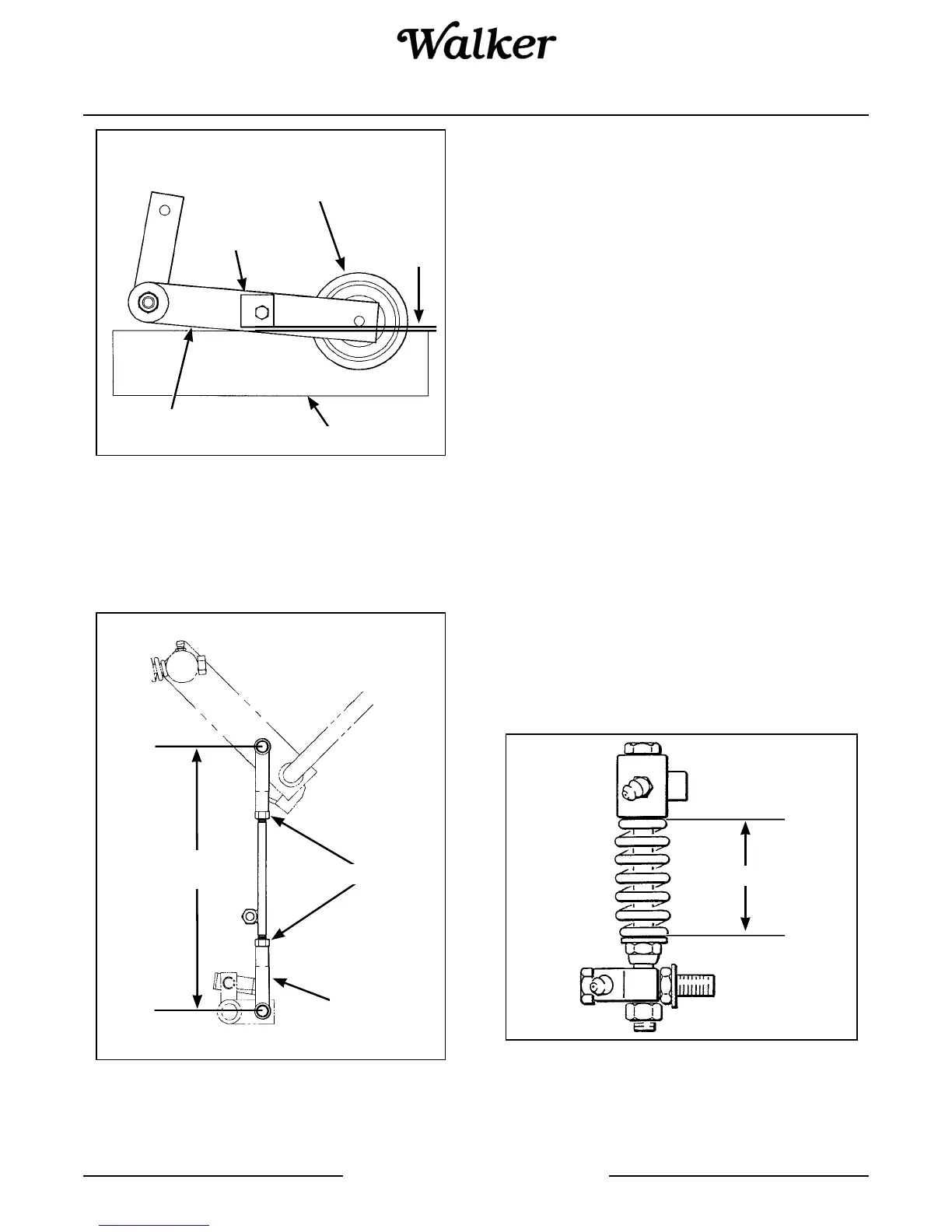

Blade Brake Band Adjustment

NOTE: The length of the actuator rod is adjusted by

disconnecting the bottom clevis and shortening or

lengthening accordingly. The standard pre-set length

of the actuator rod is set at the factory at 8-1/4 in.

(209 mm).

Brake Actuator Rod Adjustment

2. After adjustments are complete, check blade

brake action as described in CHECKING/SER-

VICING the Blade Brake Action in the Mainte-

nance Instructions Section. If blades do not

stop within five (5) seconds, check the following:

a. Recheck 1/8 in. (3 mm) gap between stop

block and chassis.

b. Make sure clutch and brake linkage are work-

ing freely (no binding).

c. Check the brake band lining.

d. Check the brake drum on the pulley. If exces-

sive wear is present, it will be necessary to

replace worn parts.

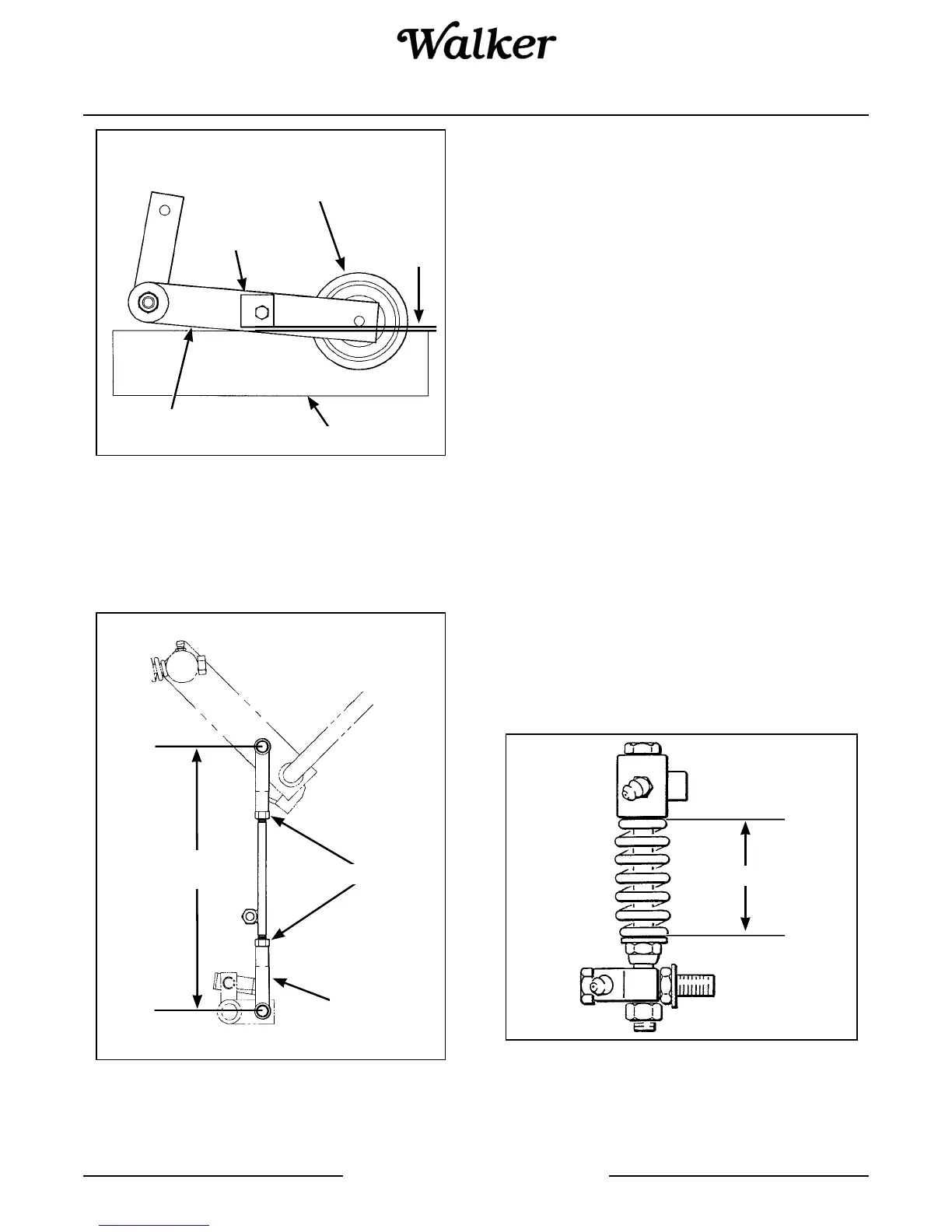

Blade Clutch (PTO) - Model MD

Clutch Engagement/Belt Tension

The clutch engagement and PTO belt tension are ad-

justed using the clutch actuator rod. Initially, after in-

stalling a new PTO belt, after 10 hours and every 100

hours thereafter, check and adjust for the three dimen-

sions in the clutch linkage as shown.

Adjust the bolt head clearance [1/4 to 3/8 in. (6 to 10

mm)] first, then adjust spring length. If adjustments are

needed more frequently than 100 hours to maintain the

linkage dimensions, it may suggest problems with pul-

ley wear or belt misalignment.

Clutch Linkage Adjustment - Disengaged

Blade Clutch

Idler Pulley

1/8 in.

(3 mm)

PTO Belt Tightener

Chassis

Stop Block

8-1/4 in.

(209 mm)

Bottom

Clevis

Locknuts

2-1/8 in. (54 mm)

Loading...

Loading...