11

OPTIONAL ACCESSORIES AND BOARDS

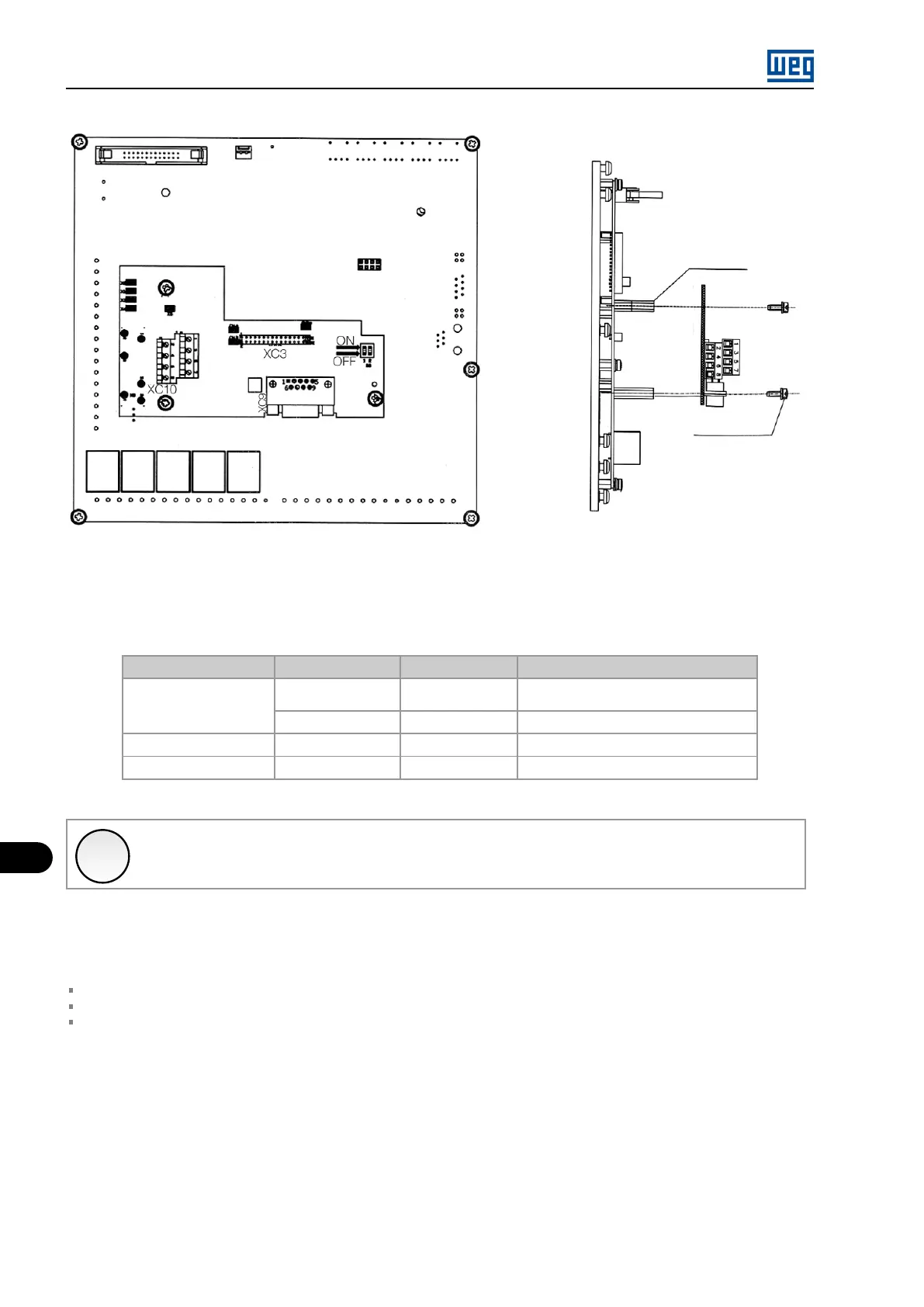

Screw M3 x 8

Torque 1Nm

Space material

10191668

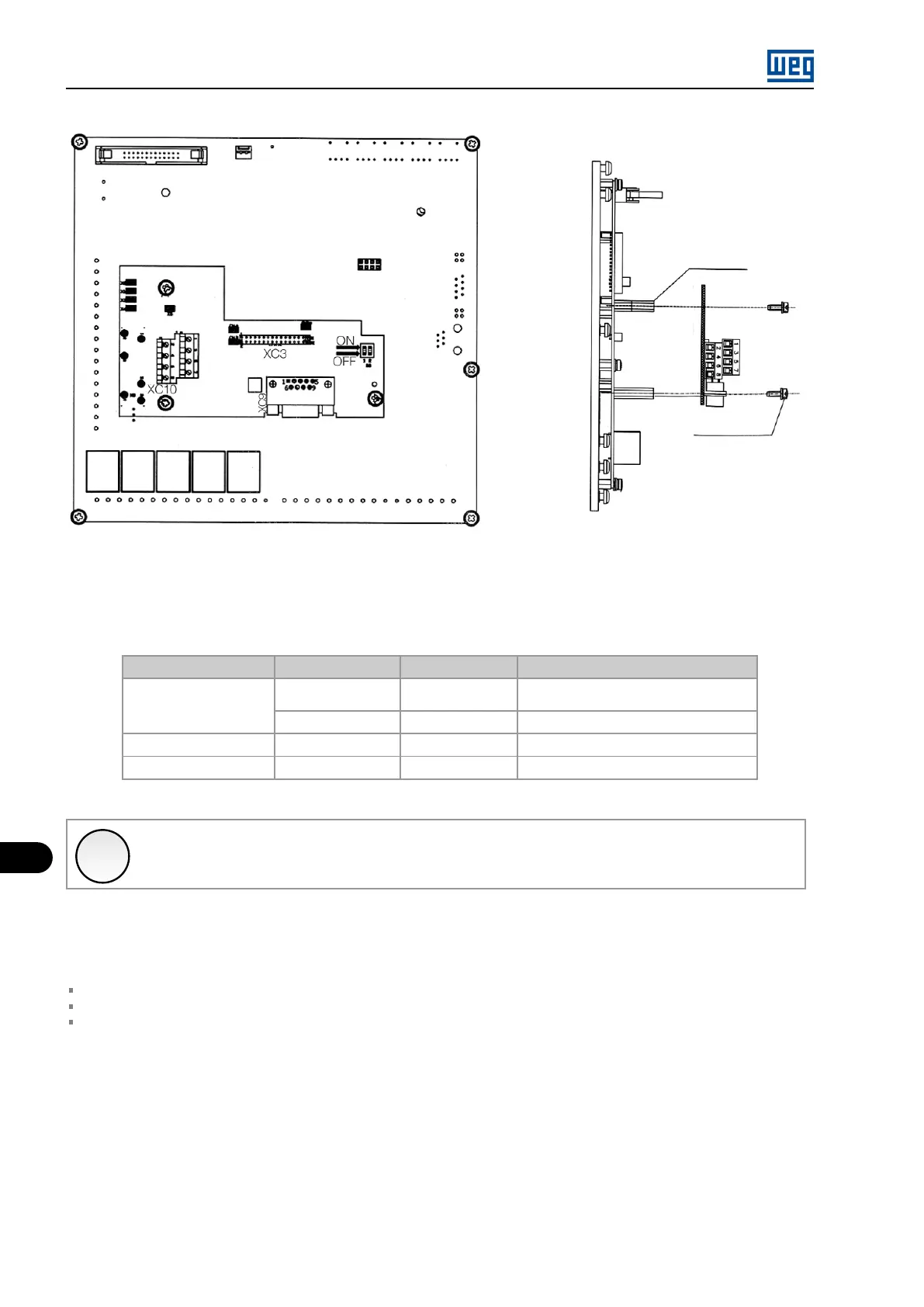

Figure 11.18: Procedure to install the EBC1 board

CONFIGURATIONS:

Table 11.16: Configurations of the setting elements - EBB board

Expansion Board

Power supply Encoder Voltage

Necessary Setting

EBC1.01

External 5 V 5 V

Switch S8 to ON, consult Figure 11.16

on page 11-17 for more details

External 8 V to 15 V 8 V to 15 V

No action

EBC1.02

Internal 5 V 5 V

No action

EBC1.03

Internal 12 V 12 V

No action

✓

NOTE!

The XC10:22 and XC10:23 terminals (see Figure 11.16 on page 11-17 ) should only be used to power the encoder if the

connection to the DB9 connector is not used.

ENCODER MOUNTING:

Follow the recommendations bellow when mounting the encoder on the motor:

Coupling the encoder directly to the motor shaft (using a flexible coupling, however without torsional flexibility);

Both the shaft and the metallic frame of the encoder must be electrically isolated from the motor (minimum distance of 3 mm);

Use good quality flexible couplings that prevent mechanical oscillations or “backlash”.

Use shielded cable for the electrical connection, keeping it as far as possible (> 25 cm) from the other wiring (power, control, etc.). Preferably,

inside a metallic conduit.

During start-up, it is necessary to program parameter P0202 (Control Type) = 4 (Encoder) to operate with speed feedback by incremental

encoder.

For further details on vector control, see the programming manual available for download on www.weg.net.

MVW01 | 11-18

Loading...

Loading...