6

MVW01 WC (WATER COOLED)

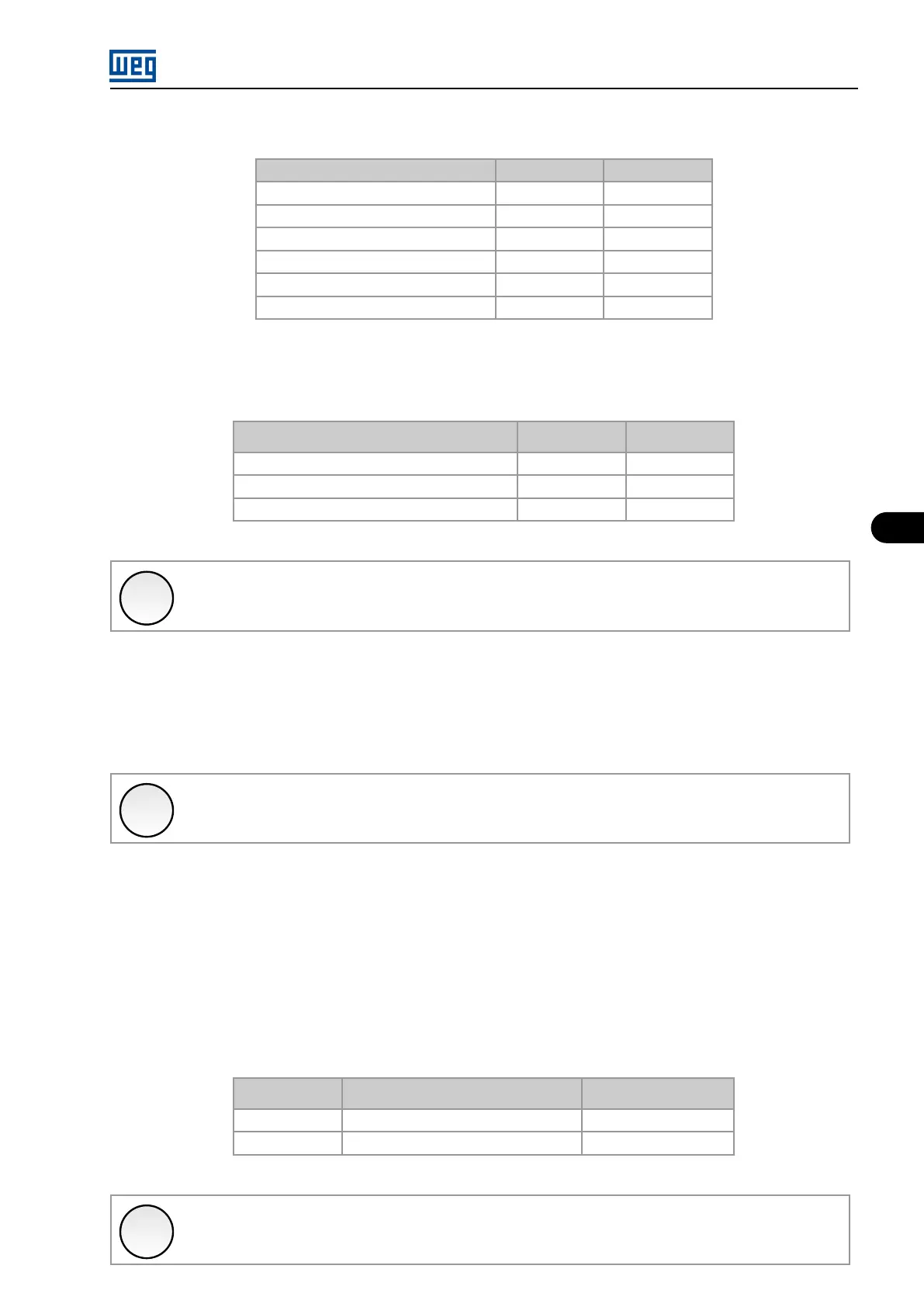

Table 6.1: Coolant Fluid Specifications Primary Circuit

Coolant fluid properties

Unit

Value

pH

6-8

Hardness °dH

< 10

Conductivity µS/cm

< 10

Chlorine

mg/l

< 10

Iron

mg/l

< 0,1

Maximum particle size

µm

< 300

For avoiding corrosion, we recommend using CorteC VpCI-649 anticorrosive. See the proportions in Table 6.2 on page 6-7 .

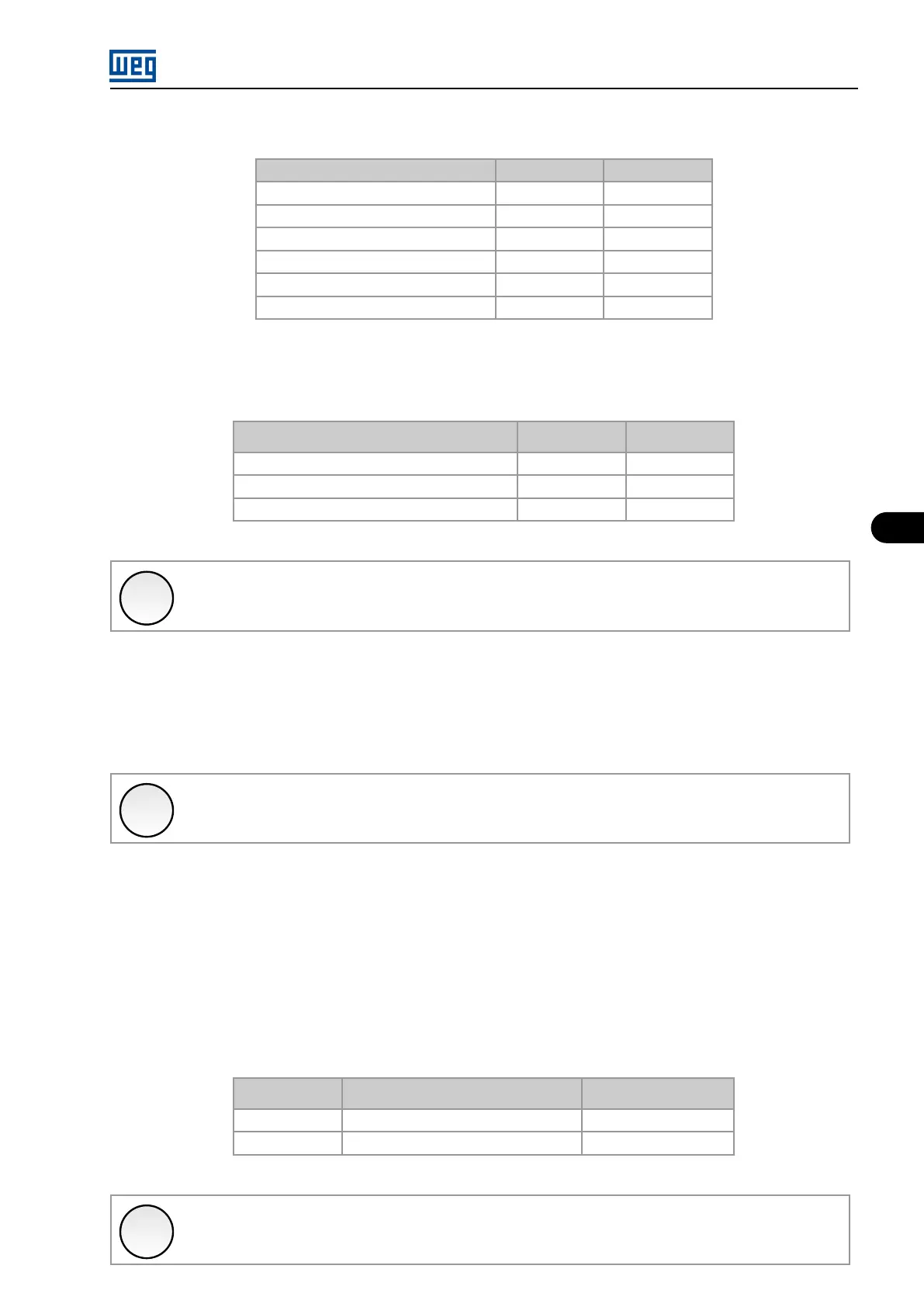

Table 6.2: Recommended proportions of products in the Coolant Fluid

Product

Temperature

above 10°C

Temperature

below 10°C

Demineralized water (WEG PN: 10562331)

90% 80%

Glycol Ethylene (WEG PN: 12014320)

9% 19%

CorteC VpCI-649 (WEG PN: 12014546)

1% 1%

✓

NOTE!

Always wear safety gloves and glasses when handling refrigerant fluid.

The quality demand in the coolant fluid in the secondary circuit is not as high as in the primary circuit, but good quality fluid will extend the

maintenance period requirement or replacement of the heat exchanger. Organic sediments must be avoided, as they cause incrustation on

the plates in the heat exchanger, reducing the thermal efficiency, and increasing the pressure drop.

The installation of a filter is recommended at the entrance to the secondary circuit, in order to prevent the entrance of particles larger than 0.5

mm. It is necessary to install a flow meter and temperature sensor on the secondary circuit to control the project parameters. The fluid in the

secondary circuit must not contain chemical residues, which may corrode the materials used in the heat exchanger in the RSW.

✓

NOTE!

If the coolant fluid does not comply with specifications and procedures, it can cause the loss of the product warranty. The

heat exchanger is not prepared to operate using salt water.

6.5.2 Hydraulic Connections of the Secondary Circuit (Customer)

Secondary Circuit: It is responsible for transferring the heat from the RSW to the customer’s circuit and it is connected by stainless steel flanged

connections model DIN 2576. These connections (pipings) have a flexible part to allow easy adjustment of the assembly.

A filter must be provided by the customer and/or final consumer to prevent the entrance of particles larger than 0.5 mm. This measure

seeks to increase the average periods between maintenance on the heat exchanger. The customer and/or final consumer must also provide

the installation of a temperature sensor at the intake to the heat exchanger for monitoring and assuring the required parameters for correct

operation of the system. If these components are not installed, then it may imply losing the warranty.

Table 6.3: Necessary Requirements for the Secondary Circuit

Model

Maximum Temperature of the

Coolant at the Inlet

Minimum flow

RSW40 38° C 145 l/min

RSW80 38° C 260 l/min

✓

NOTE!

The pressure in the secondary circuit cannot exceed 10 bar. Pressures over that can damage the heat exchanger.

MVW01 | 6-7

Loading...

Loading...