12

SPECIAL FUNCTIONS

12 SPECIAL FUNCTIONS

12.1 LOAD SHARE FUNCTION “MAIN/AUXILIARY”

Conveyors belts and overhead cranes are classic examples of applications where the torque or position control is used to maintain the conveyor

belt voltage within the limits during the operation, start and stop procedures or even in the transportation of materials in a rising of falling slope.

For motors connected to the same load, it is necessary to ensure a reliable load sharing. Such characteristic is best achieved with the use of

multiple inverters operating in speed reference mode (Main) and torque limitation mode (Auxiliary (s)).

12.1.1 Implementation Modes

Three modes to implement the load sharing function will be presented: Torque Reference, Limitation of the Torque Current and Negative Slip.

Torque reference mode and current limiting mode are for high performance applications, it is mandatory that the inverters involved in the

process be set to vector operating mode. Examples of high performance applications are: conveyor belts, mills (dual pinion, HPGR, SAG,

BALL), overhead crane and lifting. For most applications, vector operating mode with speed or position sensor is recommended.

The negative slip operating mode is for scalar control and is used exceptionally in low dynamics/performance applications. In this operating

mode, all inverters must receive the same speed reference signal, this type of load sharing is called “droop” or negative slip.

In order to implement the load sharing, the inverter assigned as main controls the load speed using all the other inverters of the process as

actuators.

The three implementation methods and the main parameters used in each method are shown below.

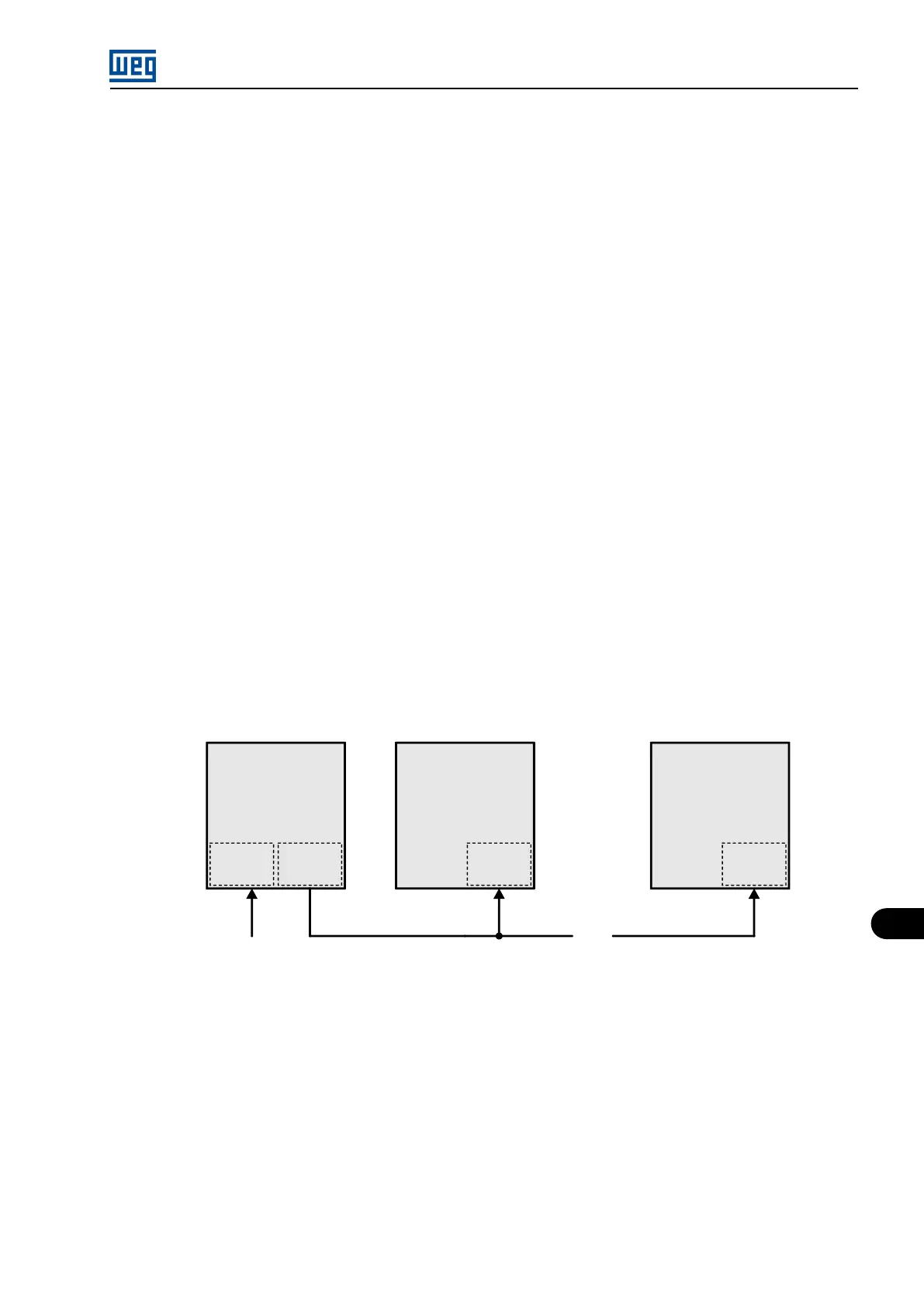

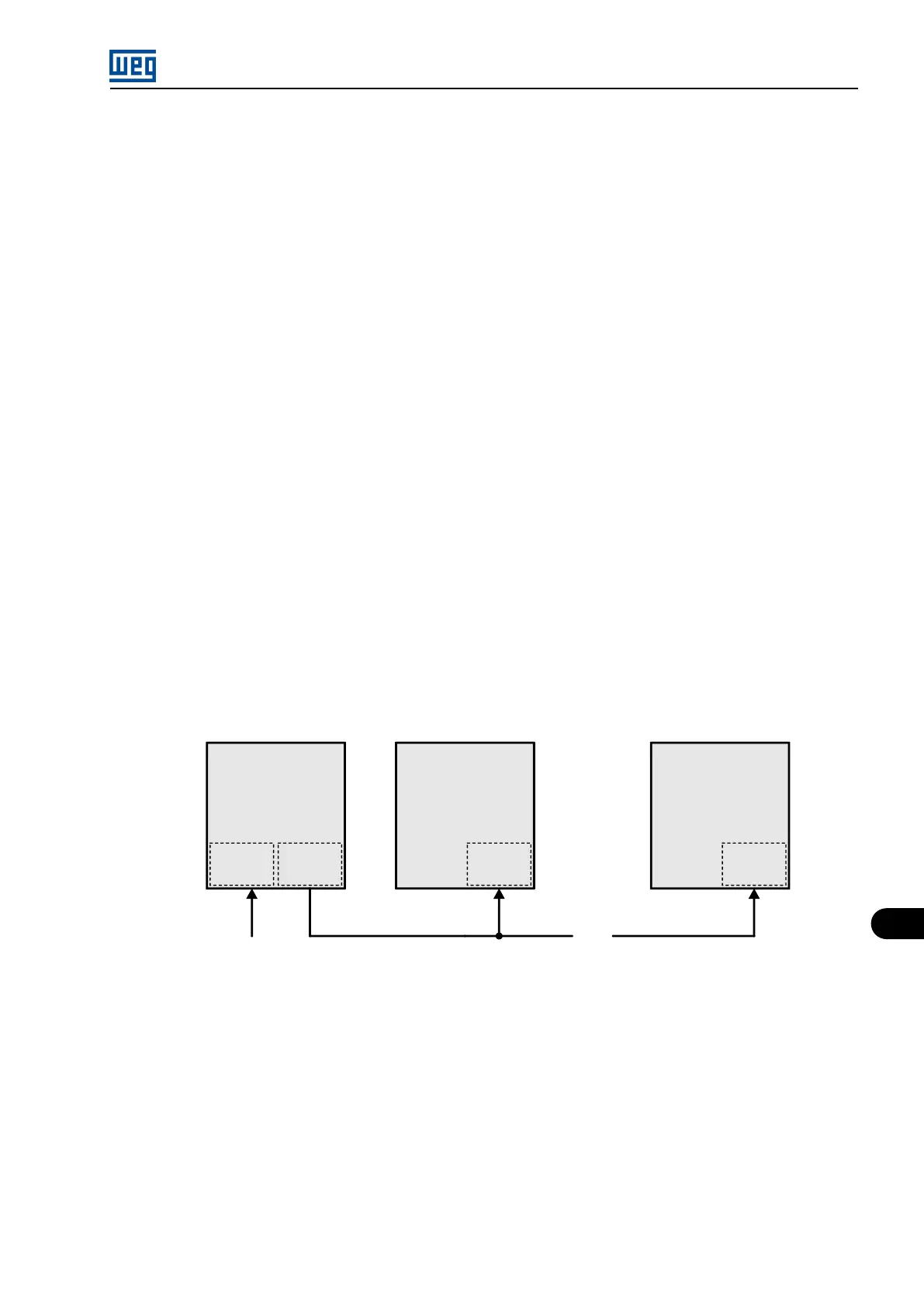

12.1.2 Torque Reference - Operation in Vector Mode

One of the possible ways to implement the load sharing function is by parameterizing the salve inverter(s) to follow an external torque reference,

which will be sent by the main inverter.

...

...

MVC3

AOX

MVW01

MVC3

AIX

MVW01

Auxiliary n

MVC3

AIX

Main

Torque ref.

Speed ref.

MVC4

Auxiliary 01

MVW01

Figure 12.1: General operation scheme of the function

In order to do so, the inverters must be parameterized as follows:

Main inverter:

Parameterize one of the analog outputs of the MVC3 control board to send the torque reference to the auxiliary (s) inverter(s). In the example

below, the analog output AO1 is parameterized.

P0652 (Analog Output 1 Function) = 188 (Inverter torque reference).

Auxiliary (s) inverter (s):

On the auxiliary inverter(s), it is necessary to parameterize an analog input of MVC3 board to receive the torque reference sent by the main

inverter.

P0740 (Analog Input 1 Function) = 1 (Torque reference).

MVW01 | 12-1

Loading...

Loading...