11

OPTIONAL ACCESSORIES AND BOARDS

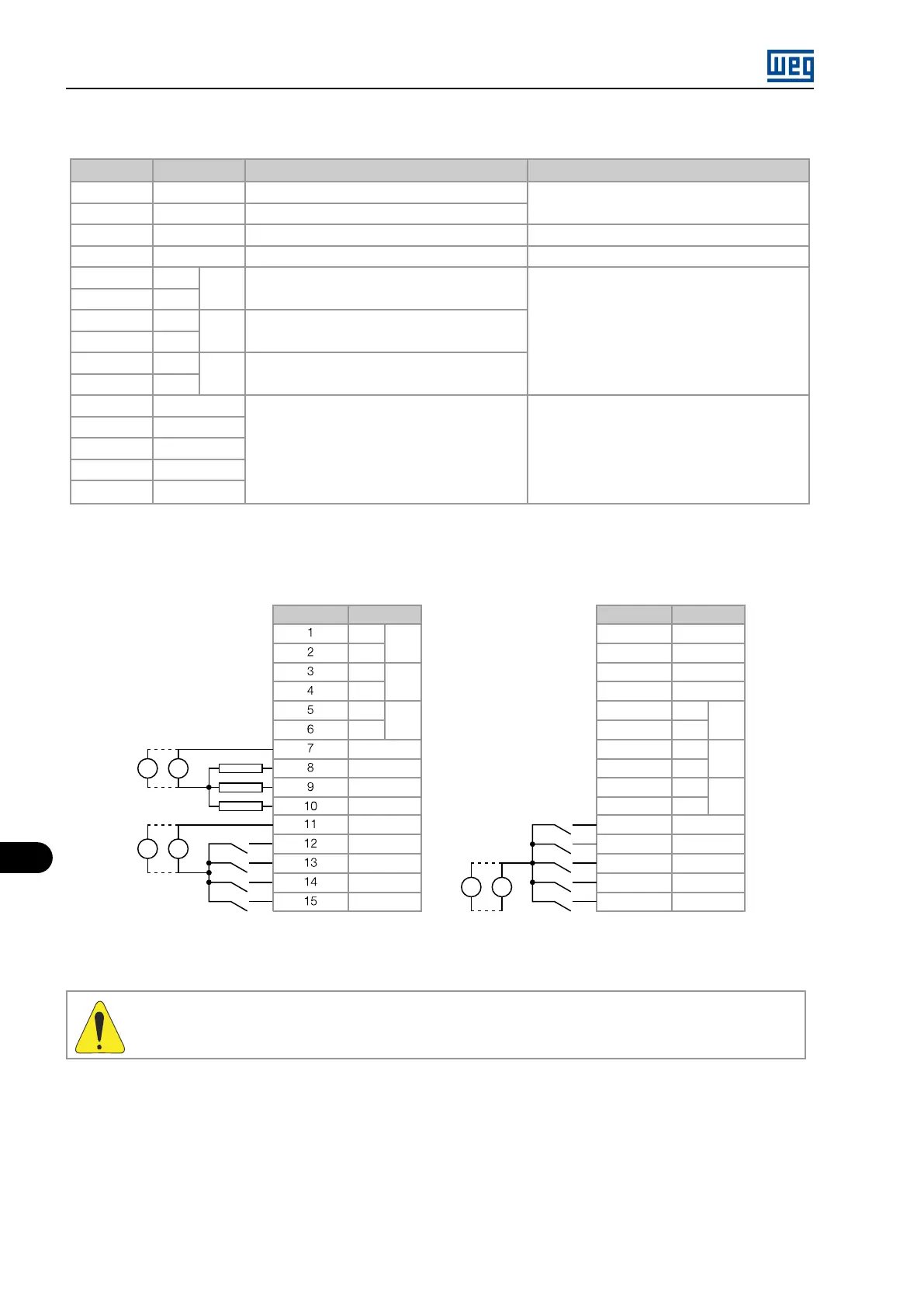

Table 11.14: Description of the XC22 connector

Connector Function

Description

Specification

16 PTC1

Motor thermistor input

Actuation: 3900 Ω, Release: 1600 K

17 PTC2

PTC

Minimum Resistance: 100 Ω

18 GND ENC

Power supply reference for the encoder inputs

-

19 +ENC

Power supply for the encoder inputs 5 Vdc regulator or (8 to 24) Vdc, 50 mA (**)

20

-

AO2

Analog output 2, 12 bits

(-10 to +10) Vcc or (0 to 20) mA

21

+

22

-

AO1

Analog output 1, 12 bits

23

+

24

-

AI1

Differential analog input 1, 12 bits

25

+

26 DI1

Bidirectional isolated digital inputs

15-30 Vdc, 11 mA @ 24 Vdc

27 DI2

28 DI3

29 DI4

30 DI5

NOTES:

NA = normally open contact.

C = common.

Connector Signal

+ENC

DI1

DI2

DI3

DI4

DI5

AO2

PTC1

PTC2

GND ENC

-

+

-

+

-

+

+

-

+

-

(*)

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

AO1

AI1

COM DI

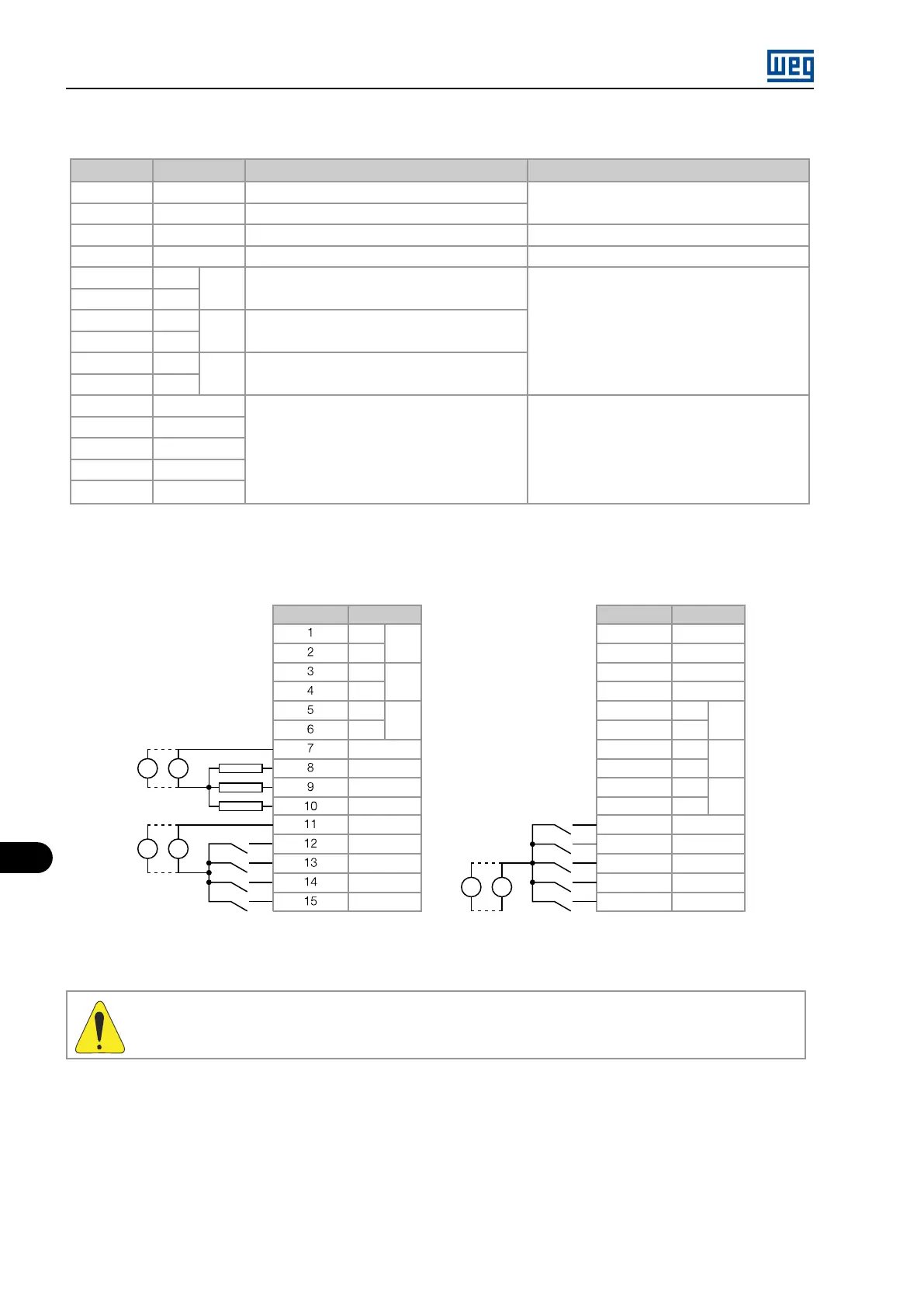

Connector Signal

NA

COM DO

DO4

DO5

DO6

COM DI

DI9

DI8

DI7

DI6

DO3

C

N

C

C

NA

DO1

DO2

+

-

+

-

+

-

+

-

(*)

(*)

Figure 11.13: Description of the XC21 and XC22 connectors

WARNING!

(*) External power supply.

(**) For current, S1 switch must be ON.

11.3 INCREMENTAL ENCODER

Applications that require more speed or positioning accuracy, a speed feedback of the motor shaft by means of incremental encoder is required.

The connection to the inverter is made through the XC9 connector (DB9) on the EBA function expansion board, or XC9 on EBB, or XC10 on

EBC.

MVW01 | 11-14

Loading...

Loading...