Setting 1: General-purpose Stall Prevention

The drive tries to decelerate within the set deceleration time. The drive pauses deceleration when the DC bus voltage exceeds

the Stall Prevention level and then continues deceleration when the DC bus voltage drops below that level. Stall Prevention

may be triggered repeatedly to avoid an overvoltage fault. The DC bus voltage level for Stall Prevention depends on the input

voltage setting E1-01.

Drive Input Voltage Stall Prevention Level during Deceleration

400 V Class 750 Vdc

575 V Class 930 Vdc

690 V Class 930 Vdc

Note: 1. Do not use this setting in combination with a Dynamic Braking Resistor or other dynamic braking options. If Stall Prevention during

deceleration is enabled, it will be triggered before the braking resistor option can operate.

2. This method may lengthen the total deceleration time compared to the set value. If this is not appropriate for the application consider

using a dynamic braking option.

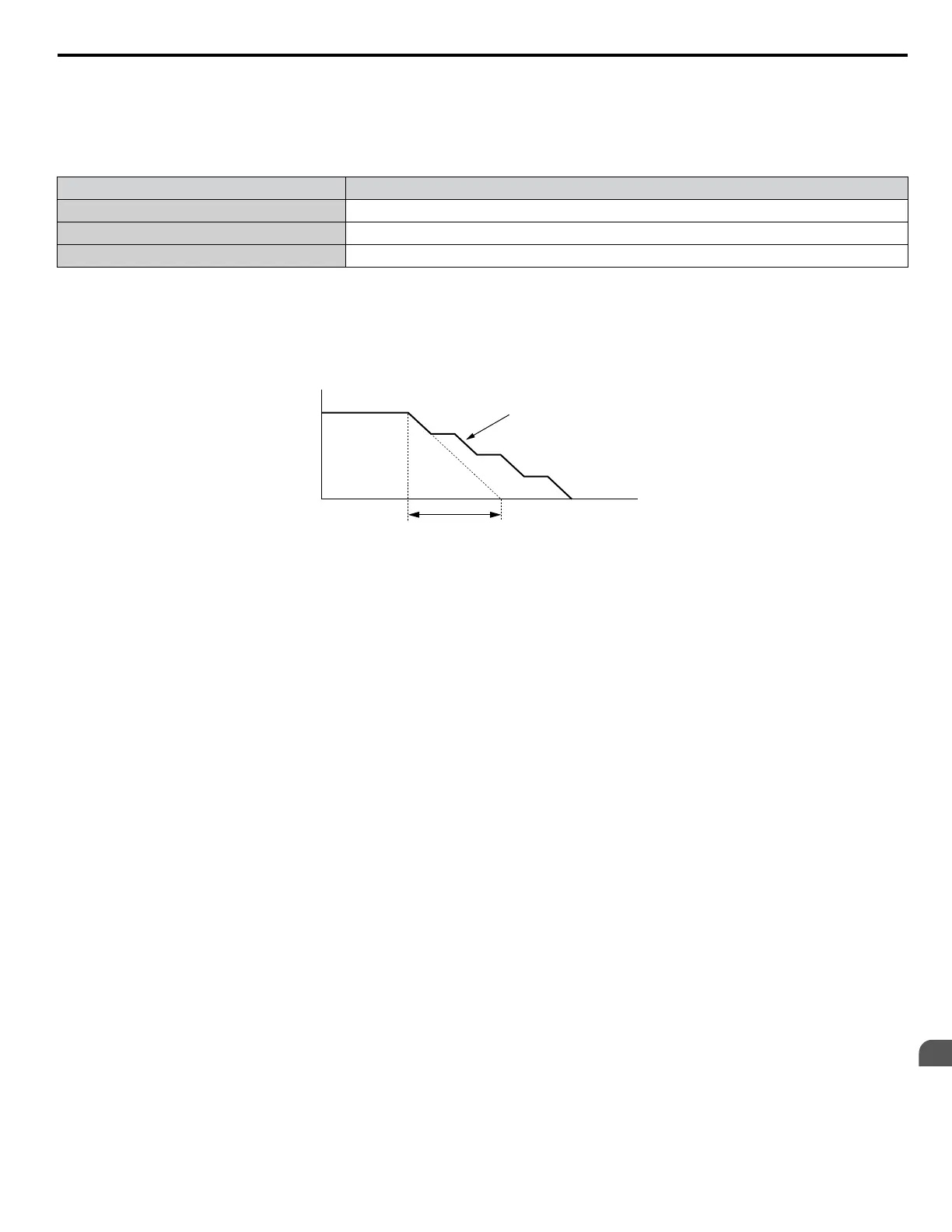

Figure 1.99 illustrates the function of Stall Prevention during deceleration.

Output Frequency

Deceleration characteristics

when Stall Prevention was

triggered during deceleration

Time

specified deceleration time

Figure 1.99 Stall Prevention During Deceleration

Setting 2: Intelligent Stall Prevention

The drive adjusts the deceleration rate so the DC bus voltage is kept at the level set to parameter L3-17. This produces the

shortest possible deceleration time while protecting the motor from stalling. The selected deceleration time is disregarded and

the achievable deceleration time cannot be smaller than 1/10 of the set deceleration time.

This function uses the following parameters for adjusting the deceleration rate:

• DC bus voltage gain (L3-20)

• Deceleration rate calculations gain (L3-21)

• Inertia calculations for motor acceleration time (L3-24)

• Load inertia ratio (L3-25)

Note: The deceleration time is not constant. Do not use Intelligent Stall Prevention in applications where stopping accuracy is a concern. Use

dynamic braking options instead.

Setting 3: Stall Prevention with dynamic braking option

Enables the Stall Prevention function while using a dynamic braking resistor. Overvoltage problems in the DC bus can occur

if Stall Prevention during deceleration is disabled (L3-04) in OLV and a dynamic braking option is installed. Set L3-04 to 3

to remedy this situation.

Setting 4: Overexcitation Deceleration 1

Overexcitation Deceleration 1 (increasing the motor flux) is faster than deceleration with no Stall Prevention (L3-04 = 0).

Setting 4 changes the selected decel time and functions to provide protection from an overvoltage trip. Refer to Overexcitation

Deceleration (Induction Motors) on page 159 for details.

Setting 5: Overexcitation Deceleration 2

Overexcitation Deceleration 2 slows down the motor while trying to maintain the DC bus voltage at the level set to parameter

L3-17. This function shortens the achievable deceleration time more than by using Overexcitation Deceleration 1. Setting 5

will shorten/lengthen the decel time to maintain the L3-17 bus level. Refer to Overexcitation Deceleration (Induction

Motors) on page 159 for details.

n

L3-05: Stall Prevention Selection during Run

Determines how Stall Prevention works during Run. Stall Prevention during run prevents the motor from stalling by

automatically reducing the speed when a transient overload occurs while the motor is running at constant speed.

1.8 L: Protection Functions

YASKAWA ELECTRIC SIEP YEAHHP 01B YASKAWA AC Drive – A1000 HHP Programming Manual

143

1

Parameter Details

Loading...

Loading...