6.1 Alarm Displays

6.1.2 Troubleshooting Alarms

6-25

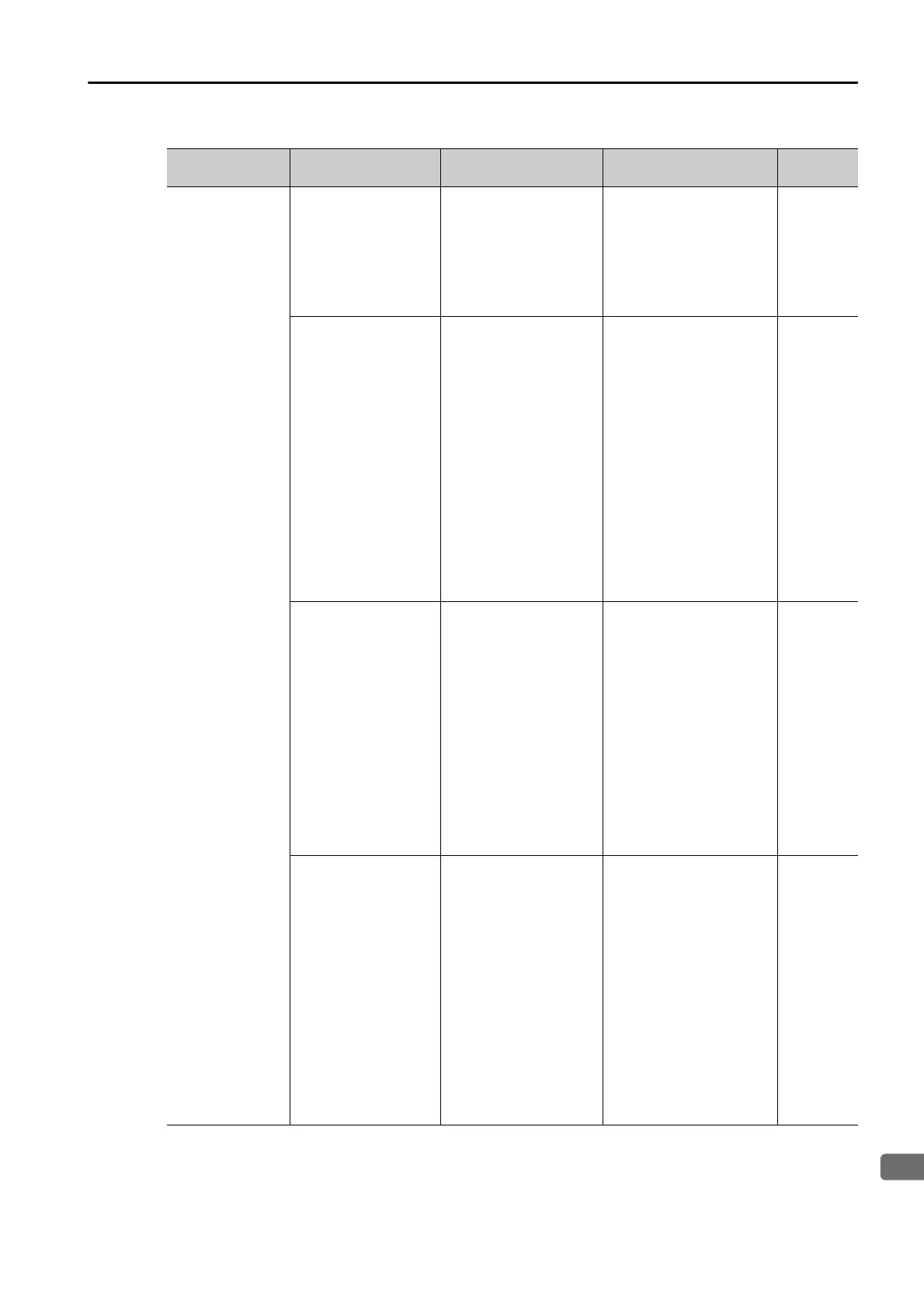

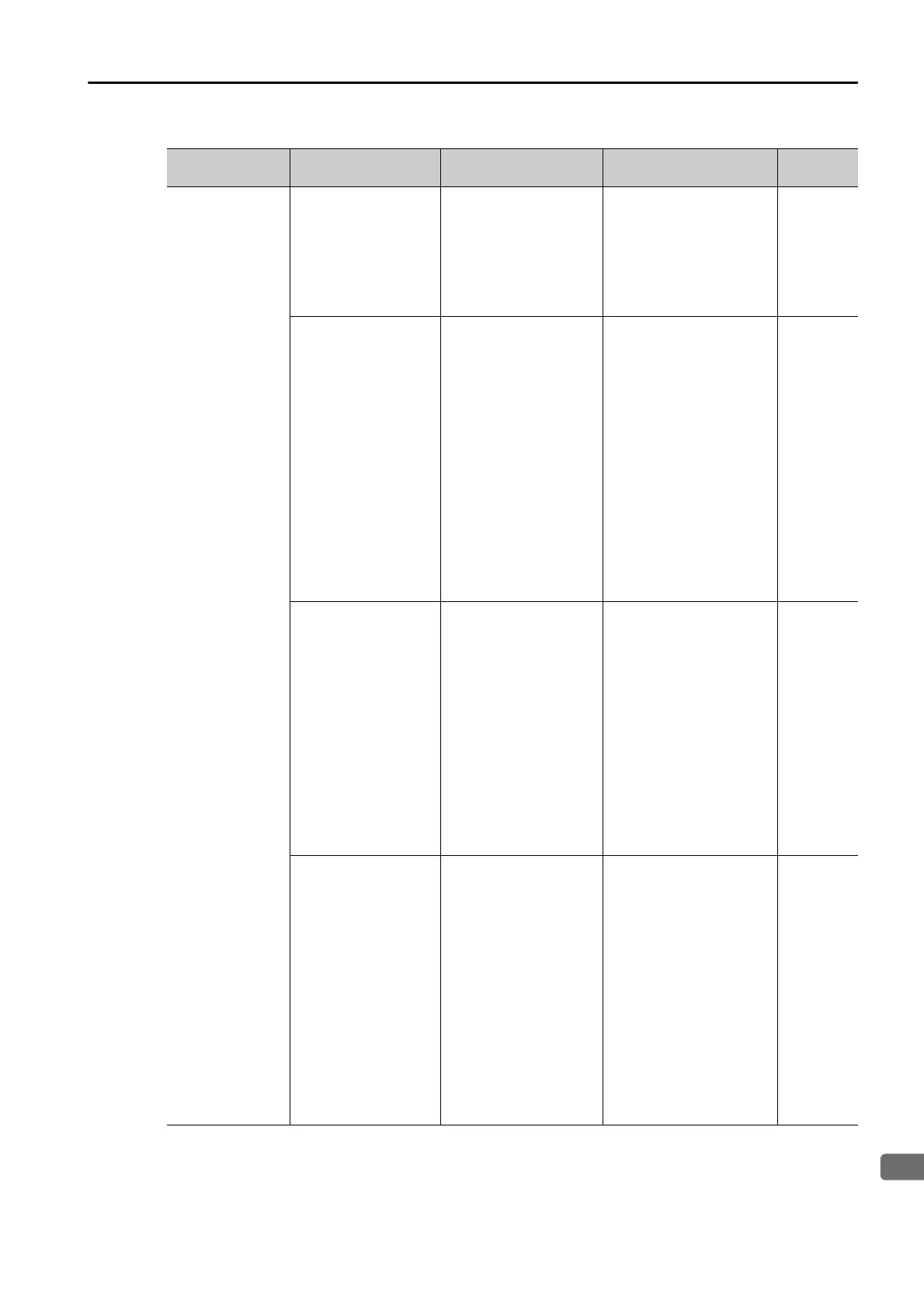

A.C50:

Polarity Detec-

tion Failure

The parameter set-

tings are not correct.

Check the linear

encoder specifications

and feedback signal

status.

The settings of Pn282

(Linear Encoder Scale

Pitch) and Pn080 =

n.X (Motor Phase

Sequence Selection) may

not match the installa-

tion. Set the parameters

to correct values.

*1

There is noise on the

scale signal.

Check to make sure

that the frame grounds

of the Serial Converter

Unit and Servomotor

are connected to the

FG terminal on the SER-

VOPACK and that the

FG terminal on the SER-

VOPACK is connected

to the frame ground on

the power supply.

And, confirm that the

shield is properly pro-

cessed on the Linear

Encoder Cable. Check

to see if the detection

reference is repeatedly

output in one direction.

Implement appropriate

countermeasures against

noise for the Linear

Encoder Cable.

–

An external force was

applied to the Moving

Coil of the motor.

–

The polarity cannot be

properly detected if the

detection reference is 0

and the speed feedback

is not 0 because of an

external force, such as

cable tension, applied to

the Moving Coil. Imple-

ment measures to reduce

the external force so that

the speed feedback goes

to 0. If the external force

cannot be reduced,

increase the setting of

Pn481 (Polarity Detection

Speed Loop Gain).

–

The linear encoder

resolution is too low.

Check the linear

encoder scale pitch to

see if it is within 100

μm.

If the linear encoder scale

pitch is 100 μm or higher,

the SERVOPACK cannot

detect the correct speed

feedback. Use a linear

encoder scale pitch with

higher resolution. (We rec-

ommend a pitch of 40 μm

or less.) Or, increase the

setting of Pn485 (Polarity

Detection Reference

Speed). However,

increasing the setting of

Pn485 will increase the

Servomotor movement

range that is required for

polarity detection.

–

Continued on next page.

Continued from previous page.

Alarm Number:

Alarm Name

Possible Cause Confirmation Correction Reference

Loading...

Loading...