4.2 Parameter Settings Related to Synchronized Stopping

4.2.1 Synchronized Stopping Mode Selection

4-4

4.2

Parameter Settings Related to Synchronized Stopping

4.2.1

Synchronized Stopping Mode Selection

Synchronized Stopping has three modes, and these modes are set with Pn665 = n.

X

(Synchronized Stopping Selection).

Synchronized Stopping Mode 1

If an alarm occurs on either axis A or axis B, position control will be performed on the synchro-

nized stopping axis using the feedback position of the active alarm axis as the target position.

Synchronized Stopping Mode 2

If an alarm occurs on either axis A or axis B, speed control will be performed on the synchro-

nized stopping axis using the feedback speed of the active alarm axis as the target speed.

Synchronized Stopping Mode 3

If an alarm occurs on either axis A or axis B, the synchronized stopping axis is also set to the

servo OFF state.

Both axes are changed to the servo OFF state almost simultaneously, and both axes are

stopped according to the Servomotor stopping method when the servo is turned OFF.

4.2.2

Synchronized Stopping End Speed Setting

Synchronized stopping will be ended when the feedback speed of the active alarm axis is less

than Pn666 (Synchronized Stopping End Speed).

Use Pn666 (Synchronized Stopping End Speed) to set the speed for judging that the Servomo-

tor has stopped and ending synchronized stopping. This parameter is valid for synchronized

stopping mode 1 and 2.

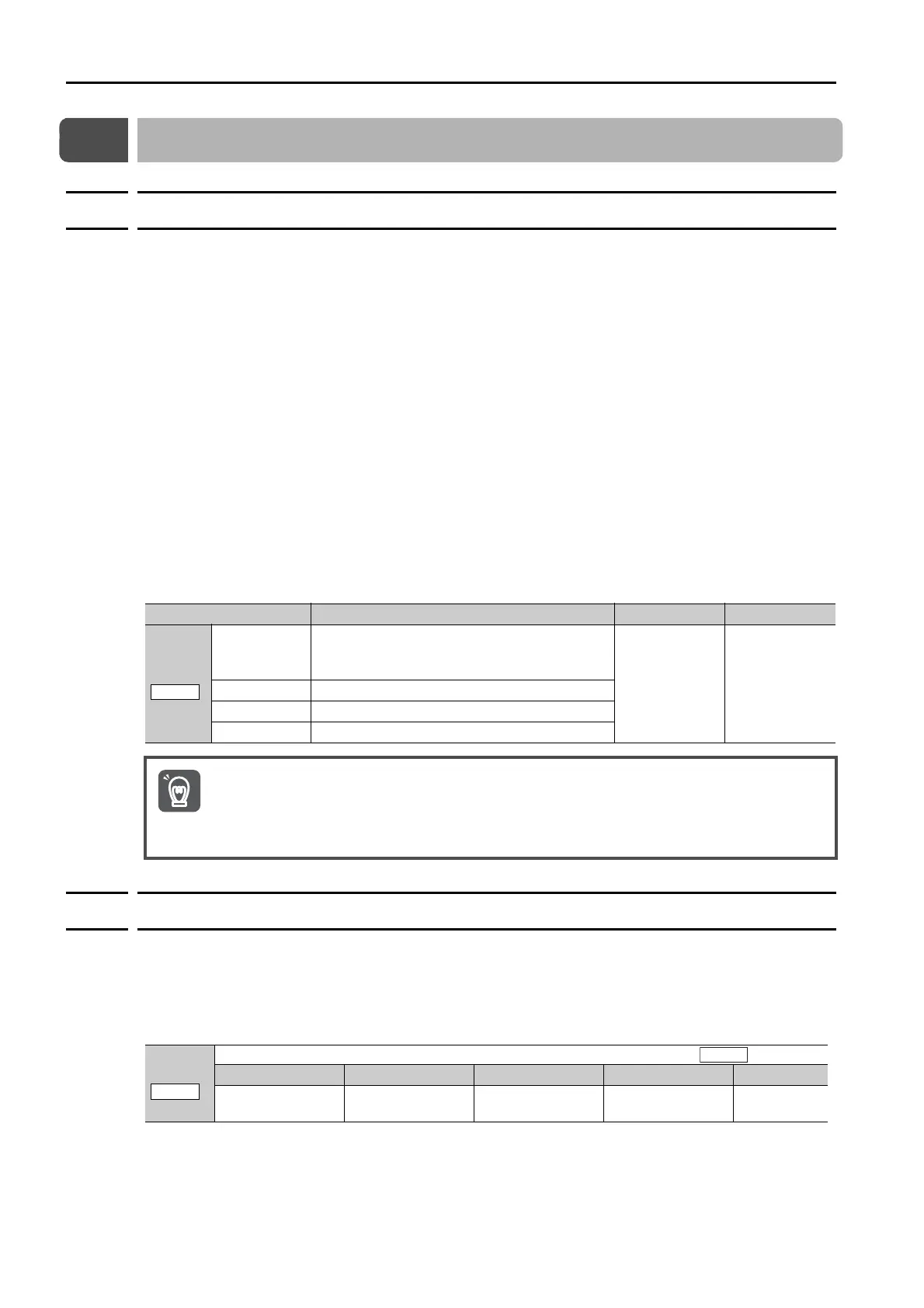

Parameter Description When Enabled Classification

Pn665

n.0

(default set-

ting)

Disable synchronized stopping.

After restart Setup

n.

1 Enable synchronized stopping mode 1.

n.2 Enable synchronized stopping mode 2.

n.3 Enable synchronized stopping mode 3.

With synchronized stopping mode 1 and 2, the Servomotor may vibrate and the deviation

between axes may increase when synchronized stopping is performed due to the mechanical

characteristics or gain setting.

Use this function by first operating the machine or product at low speed and confirming that the

deviation between axes causes no problems.

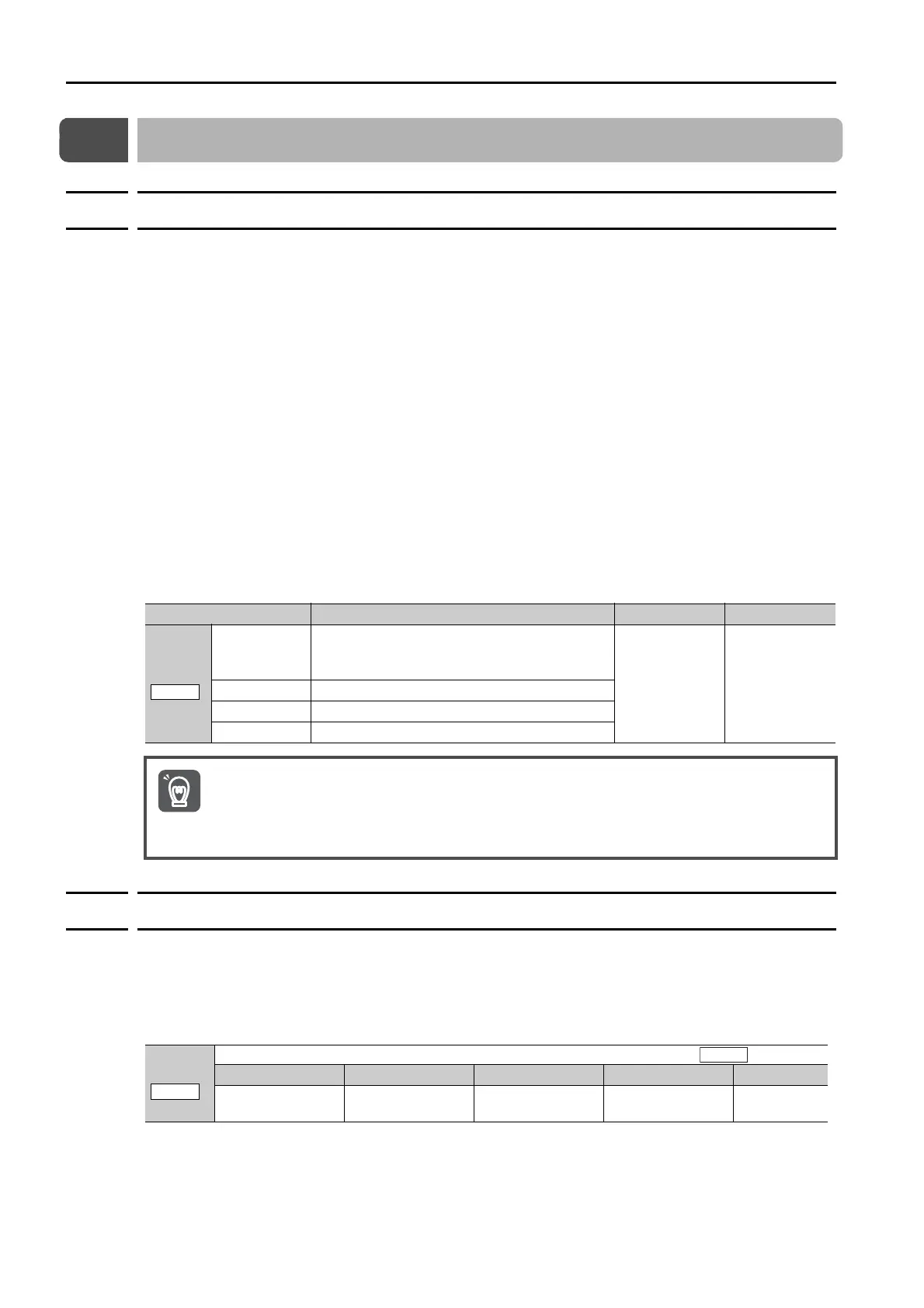

Pn666

Synchronized Stopping End Speed

Setting Range Setting Unit Default Setting When Enabled Classification

1 to 65,535

1000 reference

units/s

256 Immediately Setup

Position

Loading...

Loading...