7.1 Parameter Lists

7.1.1 Interpreting the Servo Parameter Lists

7-2

7.1

Parameter Lists

7.1.1

Interpreting the Servo Parameter Lists

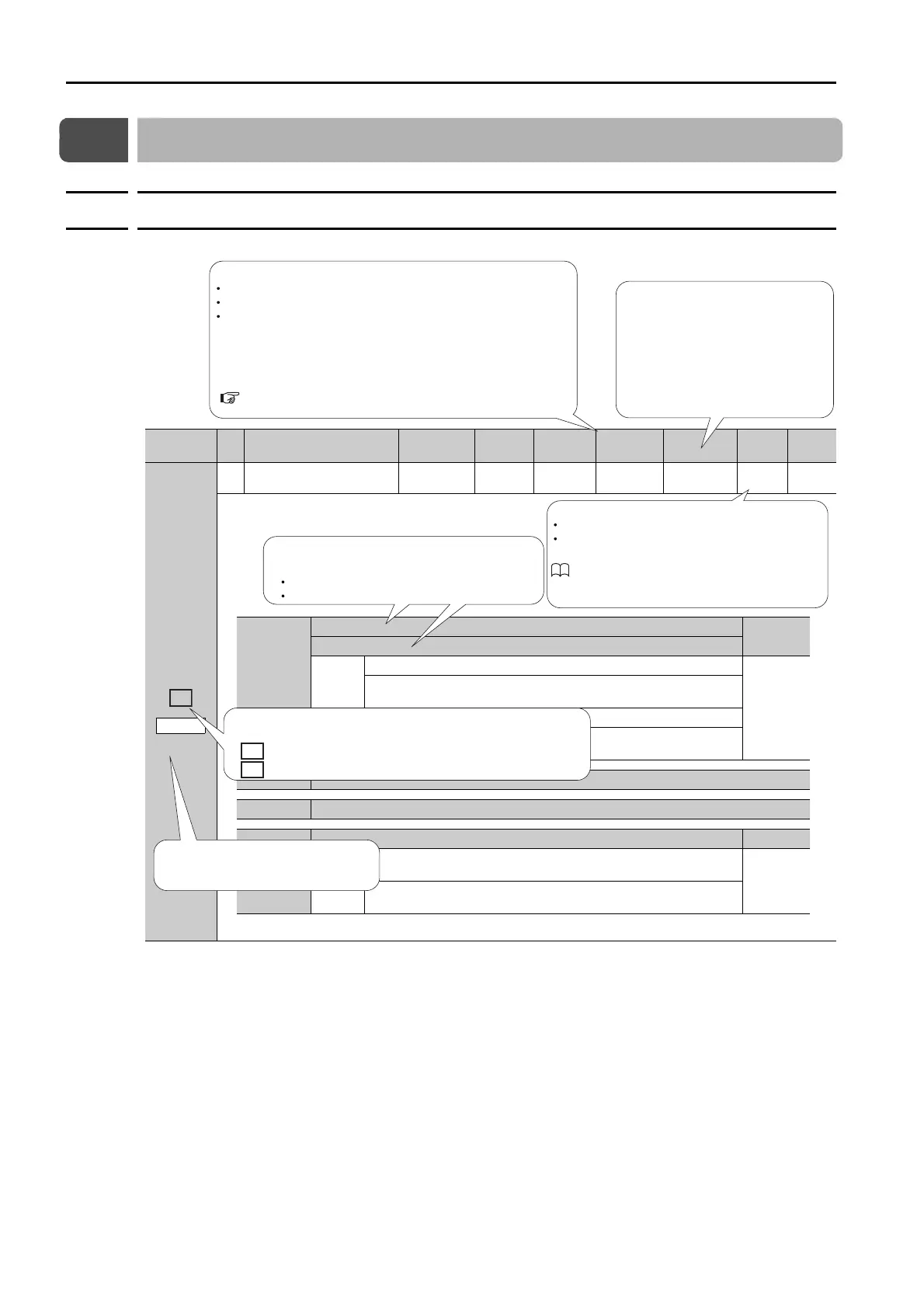

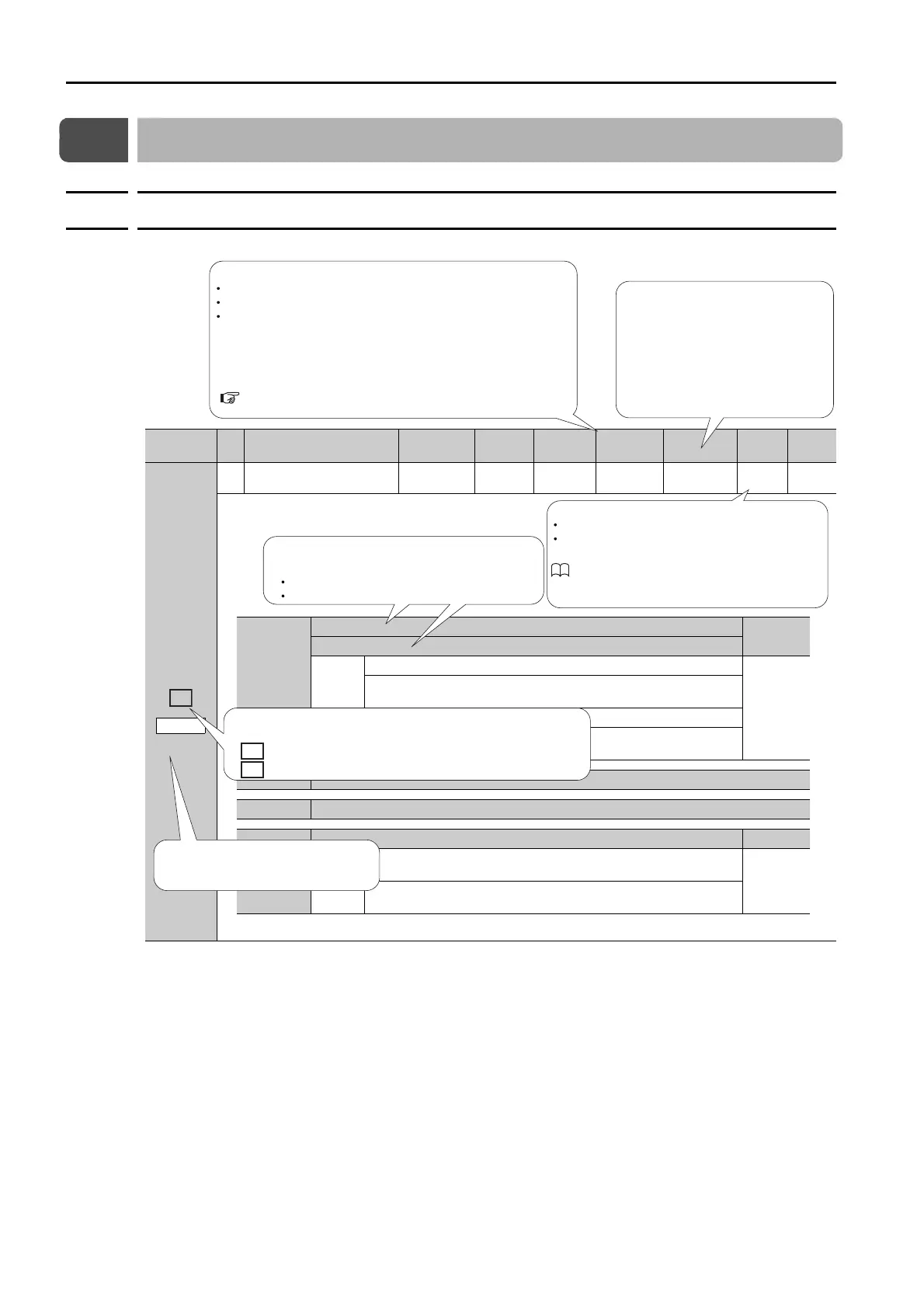

Parameter

No.

Size

Name

Setting

Range

Setting

Unit

Default

Setting

Applica-

ble Motors

When

Enabled

Classi-

fication

Refer-

ence

Pn000

2 Basic Function Selections 0

0000h to

10B1h

–

0000h All After restart Setup

–

Rotary Servomotor terms are used for parameters that are applicable

to all Servomotors. If you are using a Linear Servomotor, you need to

interpret the terms accordingly. Refer to the following section for

details.

Rotary: The parameter is used for only Rotary Servomotors.

Linear: The parameter is used for only Linear Servomotors.

All: The parameter is used for both Rotary Servomotors and Linear Servomotors.

The types of Servomotors to which the parameter applies.

Differences in Terms for Rotary Servomotors and

Linear Servomotors on page xii

Indicates when a change to the

parameter will be effective.

“After restart” indicates parameters

that will be effective after one of the

following is executed.

• The power supply is turned OFF

and ON again.

• The CONFIG command is sent.

• A software reset is executed.

n.X

Rotation Direction Selection

Reference

Movement Direction Selection

0

Use CCW as the forward direction.

–

Use the direction in which the linear encoder counts up as the for-

ward direction.

1

Use CW as the forward direction. (Reverse Rotation Mode)

Use the direction in which the linear encoder counts down as the

forward direction. (Reverse Movement Mode)

n.X Reserved parameter (Do not change.)

n.X Reserved parameter (Do not change.)

n.X

Rotary/Linear Servomotor Startup Selection When Encoder Is Not Connected

Reference

0

When an encoder is not connected, start as SERVOPACK for

Rotary Servomotor.

–

1

When an encoder is not connected, start as SERVOPACK for Lin-

ear Servomotor.

If there are differences in the parameters for Rotary

Servomotor and Linear Servomotor, information is

provided for both.

Bottom row: For Linear Servomotors

Top row: For Rotary Servomotors

Tuning

Setup

There are the following two classications.

For details, refer to the following manual.

Σ

-

7-Series

Σ

-7W SERVOPACK with

MECHATROLINK-III Communications References

Product Manual (Manual No.: SIEP S800001 29)

Symbols are provided when a parameter is valid only for a specic

prole.

•

:

Parameters that are valid only for a MECHATROLINK-II-compatible prole.

•

:

Parameters that are valid only for a MECHATROLINK-III standard servo prole.

M2

M3

This parameter applies to both axis A and

axis B. If you change the setting, the new

setting will be applied to both axes.

Loading...

Loading...