6.3 Troubleshooting Based on the Operation and Conditions of the Servomotor

6-46

6.3

Troubleshooting Based on the Operation and Conditions of the Servomotor

This section provides troubleshooting based on the operation and conditions of the Servomo-

tor, including causes and corrections.

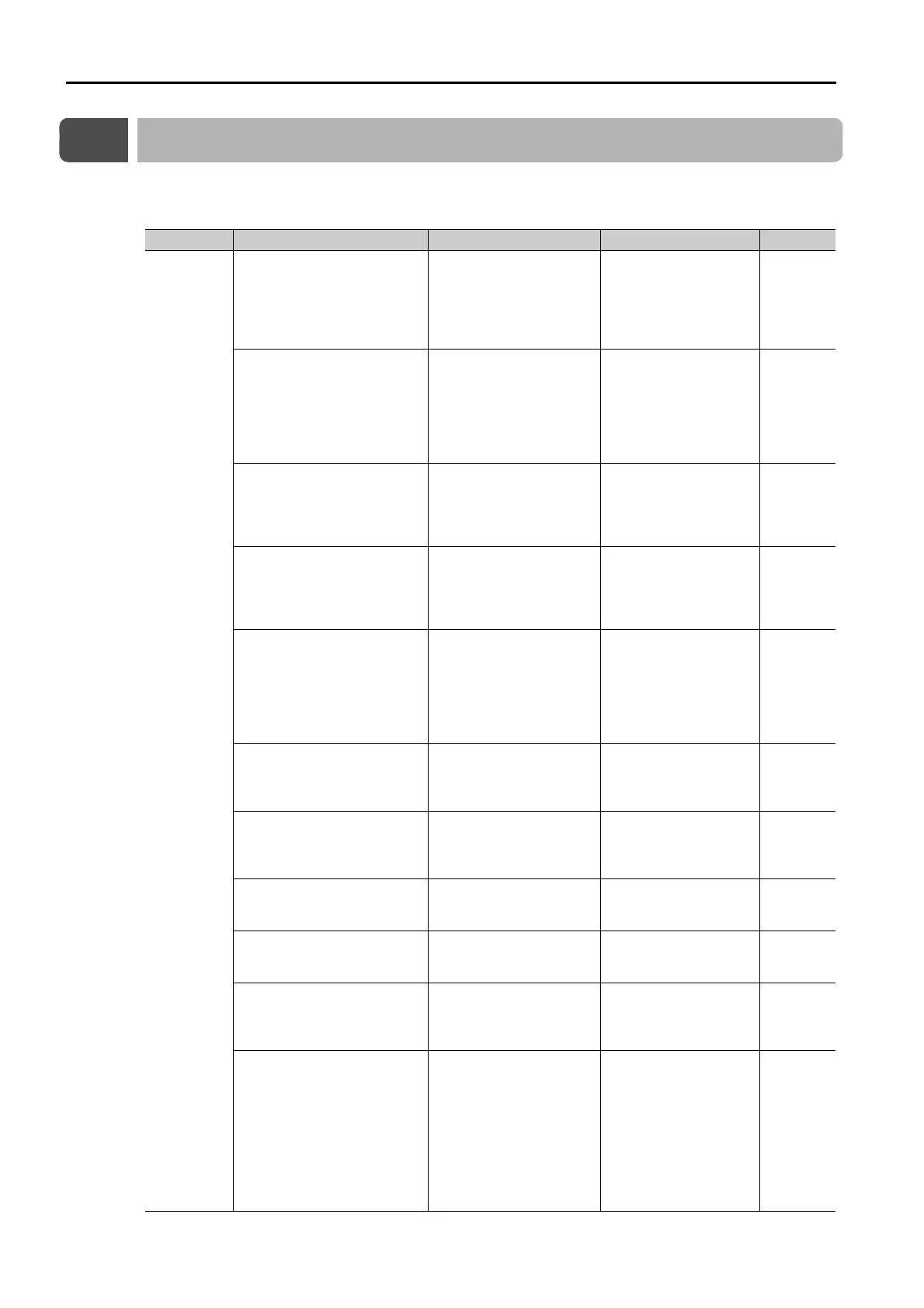

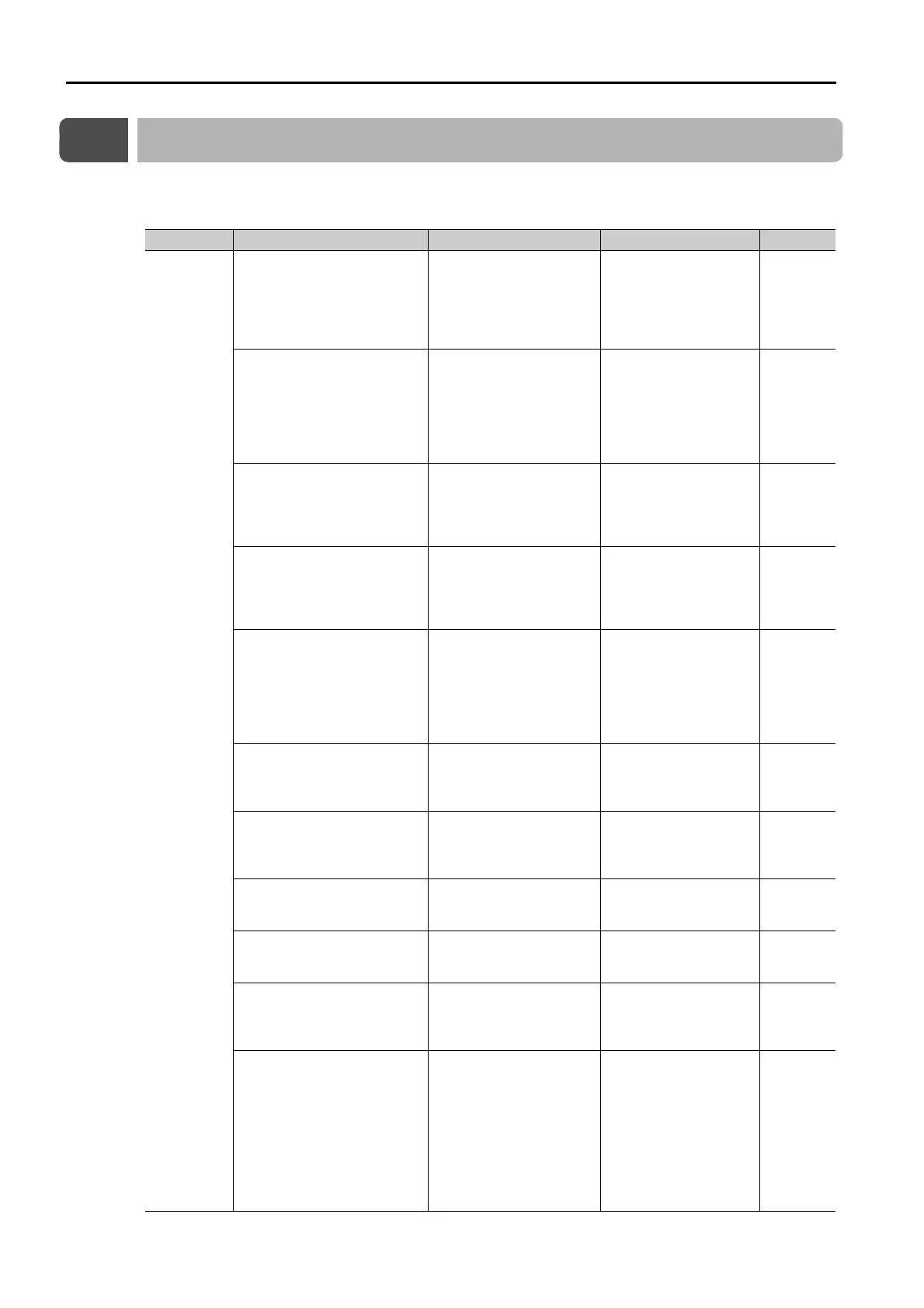

Problem Possible Cause Confirmation Correction Reference

Servomotor

Does Not

Start

The control power supply is

not turned ON.

Measure the voltage

between control power

supply terminals.

Turn OFF the power

supply to the servo

system.

Correct the wiring so

that the control power

supply is turned ON.

–

The main circuit power sup-

ply is not turned ON.

Measure the voltage

across the main circuit

power input terminals.

Turn OFF the power

supply to the servo

system.

Correct the wiring so

that the main circuit

power supply is turned

ON.

–

The I/O signal connector

(CN1) pins are not wired cor-

rectly or are disconnected.

Turn OFF the power sup-

ply to the servo system.

Check the wiring condi-

tion of the I/O signal con-

nector (CN1) pins.

Correct the wiring of

the I/O signal connec-

tor (CN1) pins.

*

The wiring for the Servomo-

tor Main Circuit Cables or

Encoder Cable is discon-

nected.

Check the wiring condi-

tions.

Turn OFF the power

supply to the servo

system.

Wire the cable cor-

rectly.

–

There is an overload on the

Servomotor.

Operate the Servomotor

with no load and check

the load status.

Turn OFF the power

supply to the servo

system.

Reduce the load or

replace the Servomo-

tor with a Servomotor

with a larger capacity.

–

The type of encoder that is

being used does not agree

with the setting of Pn002 =

n.X (Encoder Usage).

Check the type of the

encoder that is being

used and the setting of

Pn002 = n.X.

Set Pn002 = n.X

according to the type of

the encoder that is

being used.

*

There is a mistake in the

input signal allocations

(Pn50A, Pn50B, Pn511,

Pn516, or Pn590 to Pn599).

Check the input signal

allocations (Pn50A,

Pn50B, Pn511, Pn516,

and Pn590 to Pn599).

Correctly allocate the

input signals (Pn50A,

Pn50B, Pn511, Pn516,

and Pn590 to Pn599).

*

The SV_ON command was

not sent.

Check the commands

sent from the host con-

troller.

Send the SV_ON com-

mand from the host

controller.

–

The SENS_ON (Turn ON

Sensor) command was not

sent.

Check the commands

sent from the host con-

troller.

Send the commands to

the SERVOPACK in the

correct sequence.

–

The P-OT (Forward Drive

Prohibit) or N-OT (Reverse

Drive Prohibit) signal is still

OFF.

Check the P-OT and N-

OT signals.

Turn ON the P-OT and

N-OT signals.

*

The FSTP (Forced Stop

Input) signal is still OFF.

Check the FSTP signal.

• Turn ON the FSTP

signal.

• If you will not use the

function to force the

motor to stop, set

Pn516 = n.X

(FSTP (Forced Stop

Input) Signal Alloca-

tion) to disable the

signal.

*

Continued on next page.

Loading...

Loading...