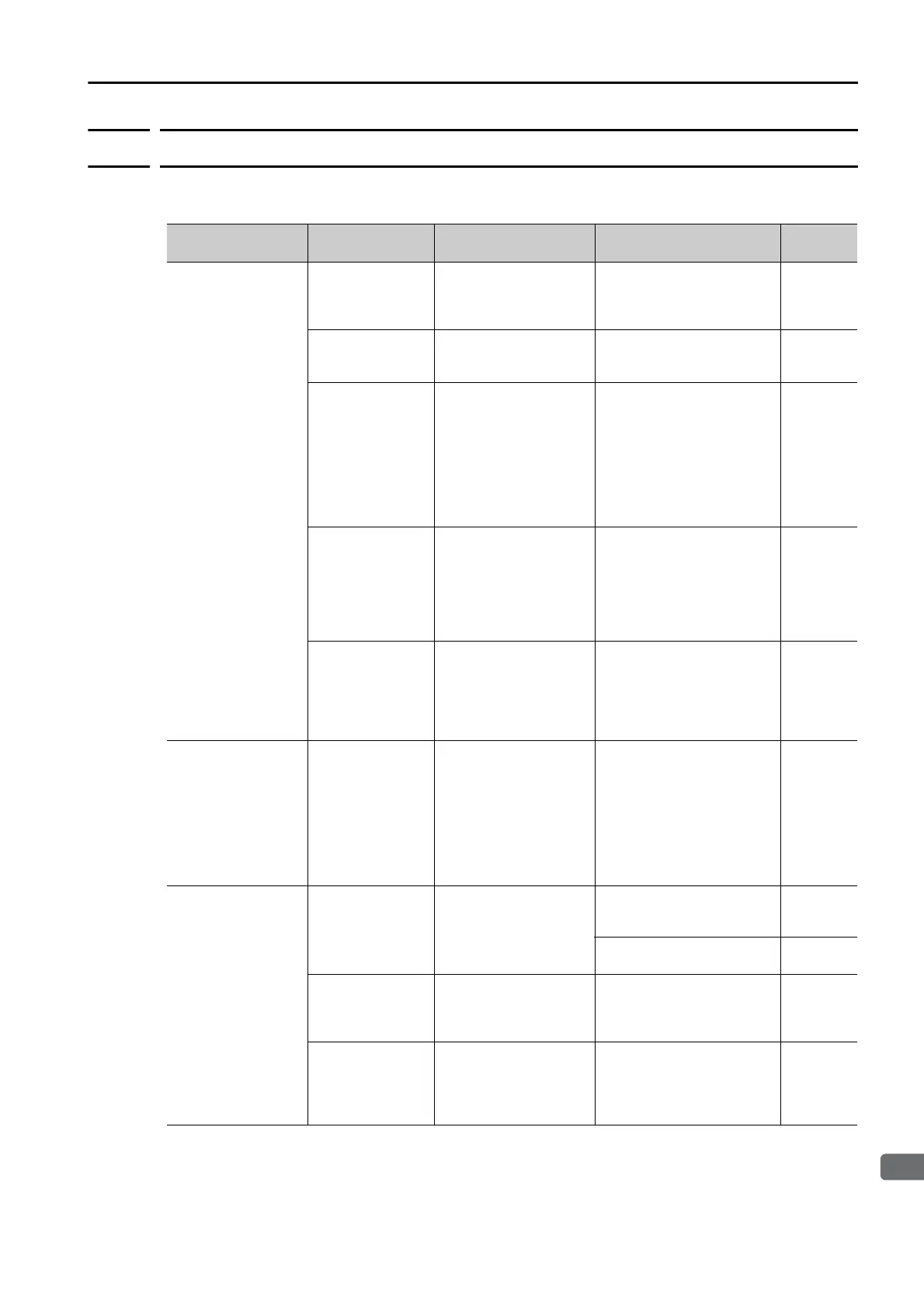

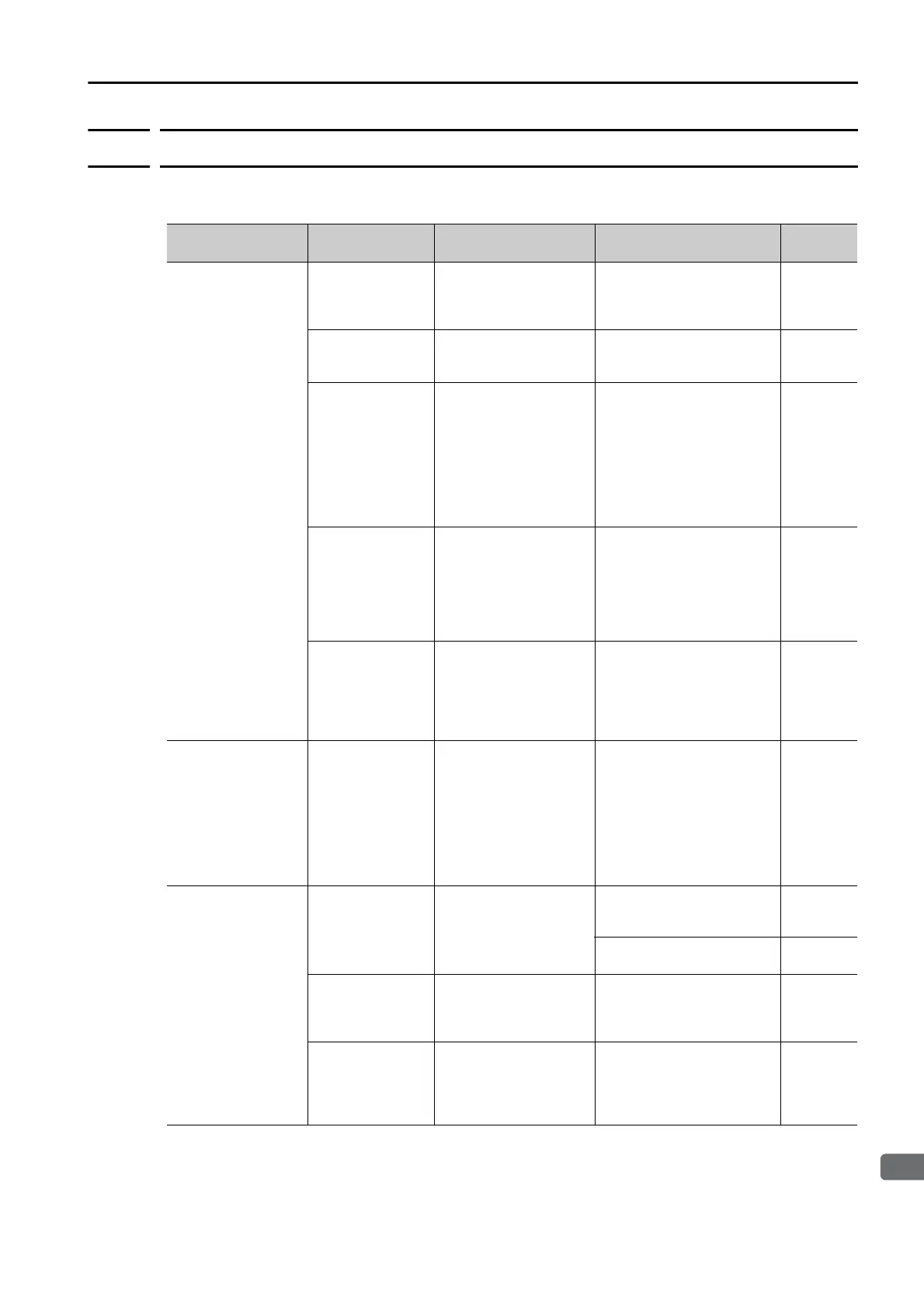

6.2 Warning Displays

6.2.2 Troubleshooting Warnings

6-39

6.2.2

Troubleshooting Warnings

The causes of and corrections for the warnings are given in the following table. Contact your

Yaskawa representative if you cannot solve a problem with the correction given in the table.

Warning Number:

Warning Name

Possible Cause Confirmation Correction Reference

A.900:

Position Deviation

Overflow

The Servomotor

U, V, and W wiring

is not correct.

Check the wiring of the

Servomotor’s Main Cir-

cuit Cables.

Make sure that there are no

faulty connections in the

wiring for the Servomotor

and encoder.

–

A SERVOPACK

gain is too low.

Check the SERVO-

PACK gains.

Increase the servo gain,

e.g., by using autotuning

without a host reference.

*

The acceleration

of the position ref-

erence is too high.

Reduce the reference

acceleration and try

operating the SERVO-

PACK.

Reduce the acceleration of

the position reference using

a MECHATROLINK com-

mand. Or, smooth the posi-

tion reference acceleration

by selecting the position

reference filter (ACCFIL)

using a MECHATROLINK

command.

–

The excessive

position deviation

alarm level (Pn520

× Pn51E/100) is

too low for the

operating condi-

tions.

Check excessive posi-

tion deviation alarm

level (Pn520 × Pn51E/

100) to see if it is set to

an appropriate value.

Optimize the settings of

Pn520 and Pn51E.

*

A failure occurred

in the SERVO-

PACK.

–

Turn the power supply to

the SERVOPACK OFF and

ON again. If the alarm still

occurs, the SERVOPACK

may be faulty. Replace the

SERVOPACK.

–

A.901:

Position Deviation

Overflow Alarm at

Servo ON

The position devi-

ation when the

servo was turned

ON exceeded the

percentage set

with the following

formula:

(Pn526 × Pn528/

100)

–

Optimize the setting of

Pn528 (Position Deviation

Overflow Warning Level at

Servo ON).

–

A.90D:

Position Deviation

Between Axes Over-

flow Warning

Twi sti n g of

mechanical parts

has occurred

between axes A

and B.

Check the position

deviation between the

axes.

Resolve the twisting of

mechanical parts between

the axes.

–

Set the Position Correction

Table to appropriate values.

page 3-7

Axis A and axis B

are not synchro-

nized with the ref-

erence.

Check the reference

position for Axis A and

Axis B.

The host controller should

command the system to

synchronize operation of

axis A and axis B.

–

The value of

(Pn66A

× Pn669/

100) is low for the

operating condi-

tions.

Check if the value of

(Pn66A

× Pn669/100) is

appropriate.

Set Pn66A and Pn669 to

appropriate values.

page 5-3

Continued on next page.

Loading...

Loading...