iii

About this Manual

This manual provides information on the Σ-7-Series AC Servo Drive Σ-7W SERVOPACK for Gantry

Applications.

Read and understand this manual to ensure correct usage of the Σ-7-Series AC Servo Drives.

Keep this manual in a safe place so that it can be referred to whenever necessary.

Outline of Manual

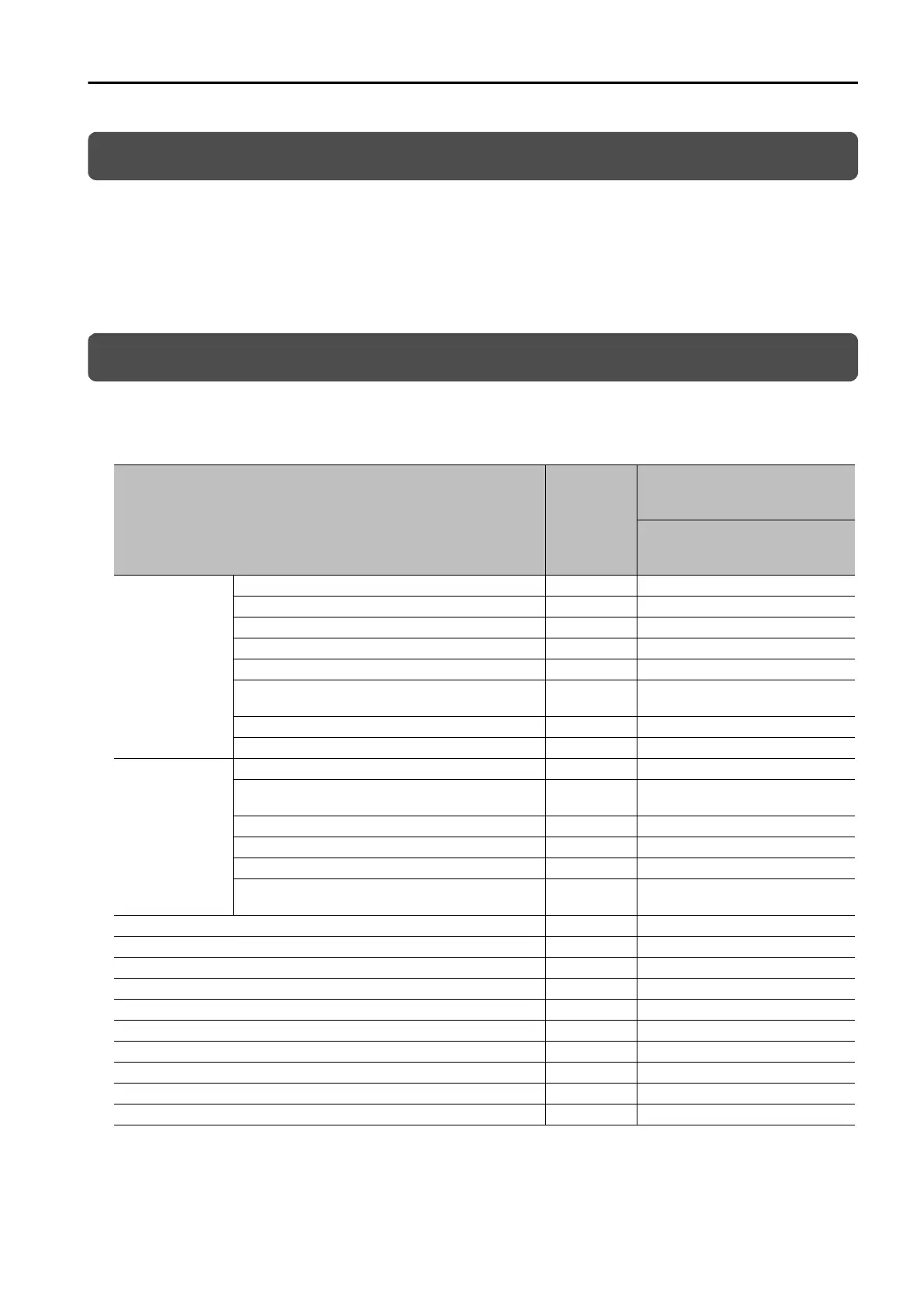

The contents of the chapters of this manual are described in the following table.

When using the

Σ

-7-Series for Gantry Applications, read and understand this manual and the manuals

given in the following table.

Item This Manual

Σ-7-Series AC Servo Drive

Σ-7W SERVOPACK

Product Manual

MECHATROLINK-III

Communications Reference

(Manual No.: SIEP S800001 29)

Basic Informa-

tion

on SERVO-

PACKs

The

Σ-7 Series – 1.1

Product Introduction 1.1 –

Interpreting the Nameplate – 1.2

Part Names – 1.3

Model Designations 1.2 –

Combinations of SERVOPACKs and

Servomotors

–1.5

Functions 1.4 –

SigmaWin+ 1.5 –

Selecting a

SERVOPACK

Ratings 2.1 –

SERVOPACK Overload Protection

Characteristics

2.2 –

Specifications 2.3 –

Block Diagrams – 2.2

External Dimensions – 2.3

Examples of Standard Connections between

SERVOPACKs and Peripheral Devices

–2.4

SERVOPACK Installation – Chapter 3

Wiring and Connecting SERVOPACKs – Chapter 4

Basic Functions That Require Setting before Operation – Chapter 5

Application Functions – Chapter 6

Trial Operation and Actual Operation – Chapter 7

Tuning – Chapter 8

Monitoring – Chapter 9

Position Correction Table Chapter 3 –

Synchronized Stopping Chapter 4 –

Position Deviation between Axes Overflow Detection Chapter 5 –

Continued on next page.

Loading...

Loading...