3.1 Outline

3-2

3.1

Outline

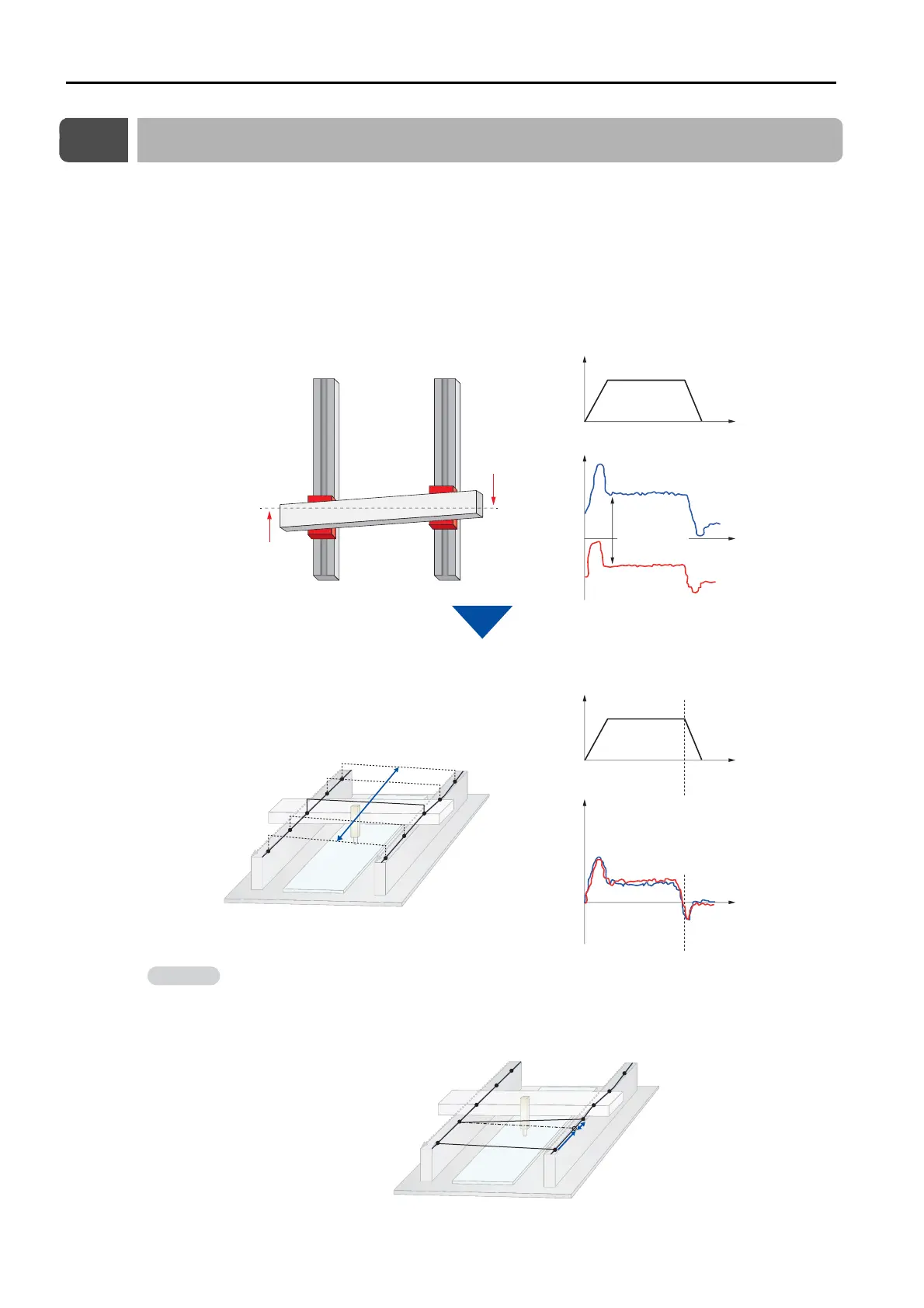

The Position Correction Table is used to drive the Servomotors while correcting the position

based on the correction amounts set in the table in order to minimize wasted torque produced

by mechanical differences in the machine.

Using this function can reduce cycle time because it can drive the Servomotors without pro-

ducing wasted torque between two axes.

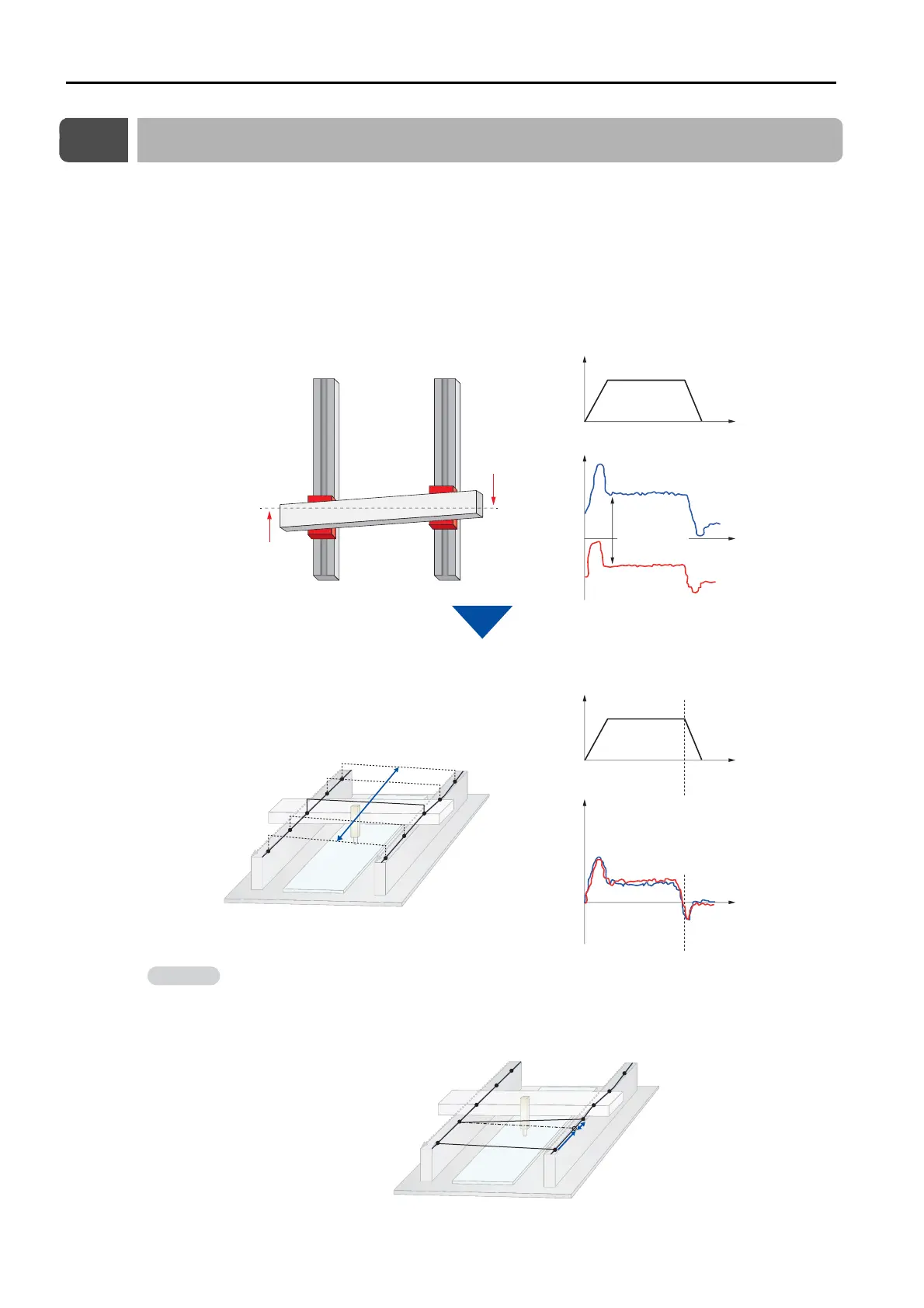

The SERVOPACK adds the correction amount to the reference position from the host control-

ler, and then it moves the slave axis.

For this reason, the coordinate position of the slave axis is offset from the reference position

from the host controller by only the added correction amount.

Master axis

Slave axis

Pm1

Pm2

Pm3

Pm4

Pm5

Ps1

Ps2

Ps3

Ps4

Ps5

Master axisSlave axis

Torque

Torque

Speed

Time

Master axis

0

0

Slave axis

Time

Torque

Time

Torque

Speed

Time

Tension is produced between the axes when the

Servomotors are driven due to mechanical

differences, and this produces wasted torque.

Wasted torque produced due to mechanical differences

can be minimized by driving the Servomotors while

correcting the position of the slave axis based on the

correction amounts set in the table.

Wasted torque is

not produced

between the

master and slave

axes.

This much

wasted

torque is

produced.

Master axisSlave axis

Reference position

from host controller

Correction amount

Loading...

Loading...