Procedure of draining liquid from the tyres

F227

Antifreeze solution for tyre filling

Solution preparation:

1. Dry calcium chloride CaCl

2

is added to water, never the other way round!

2. The solution is not dangerous, but it is necessary to work carefully with it. Remove spilt drops with clean

water.

3. Before filling leave the solution to cool down. Observe the prescribed quantity of hydrated lime.

4. The solution must not get in contact with metal parts and the electric installation! The solution is not

harmful for the tube valve.

5. The antifreeze solution with the above mentioned composition must not be used in the cooling system!

6. After drainin

dis

ose of the antifreeze li

uid as s

ecial waste

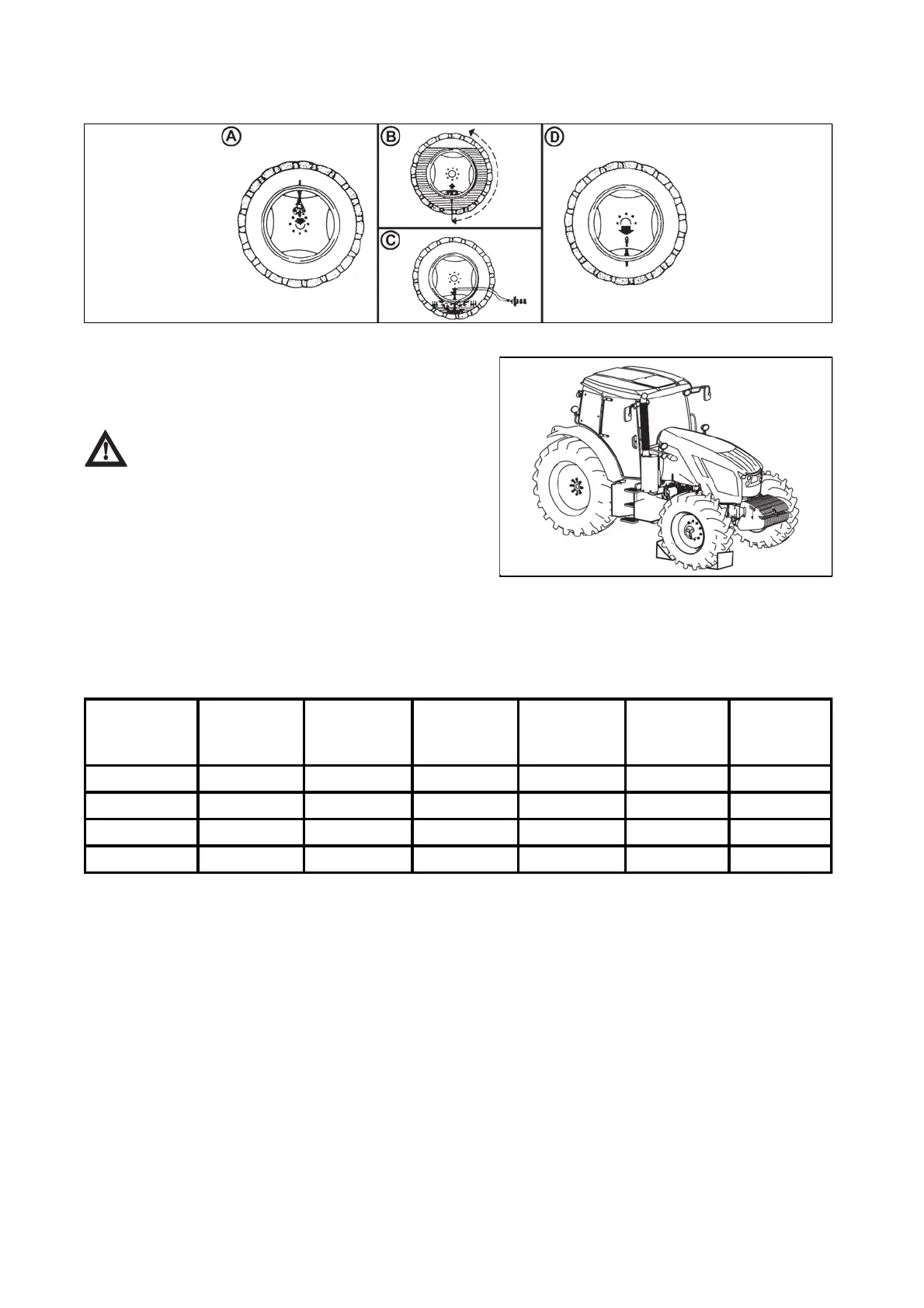

1. Unload the tyre by lifting the tractor and turn it with the

valve upwards (A).

2. Deflate the tyre and unscrew the valve insert; turn the

wheel with the valve downwards.

During draining of liquid vacuum may occur in

the tyre. Therefore, turn the wheel time after time to

get the valve to the upper position (B).

3. Remove the rest of the liquid after screwing on the

adapter for water filling by supplying pressurized air (C).

4. Blow out the liquid until it stops running through the

tube of the air adapter.

5. Unscrew the adapter for water filling

6. Screw the air part of the valve back on and inflate the

tyre to the prescribed pressure.

7. Screw the protective cap on the valve.

8. Drain the liquid from the other tyre in the same way.

C15N132

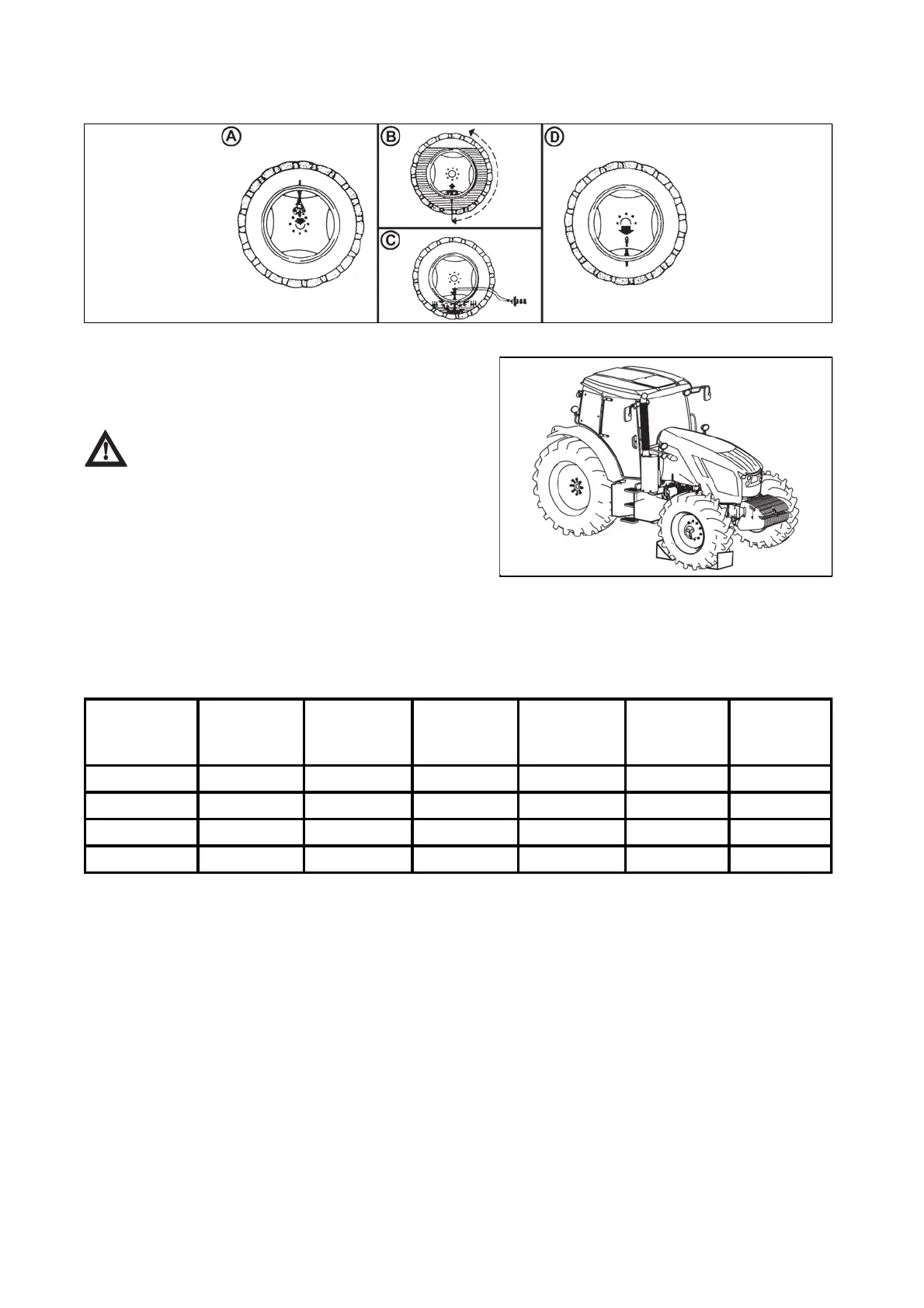

Water for

solution

preparation

Calcium

chloride

CaCl

2

Hydrated lime Solution

density at 20°

C

Freezing

point approx.

Total volume Added

weight

(l) (kg) (kg) (°C) (l) (kg)

45 11.8 0.21 1.13 -18 50 57

45 13.9 0.23 1.18 -25 50 59

45 15.4 0.25 1.21 -30 50 61

Loading...

Loading...