Precautions Whenever handling

valves,

take the

necessary precautions

not to

pollute the

vacuum

circuit and, to keep the valve and valve seat free

of particles which create leaks.

The

valve, particularly the sealing

surfaces,

should only be handled

with clean,

lint-free

gloves.

It should only be installed in a clean system.

Dismantling For the valve

assembly/disassembly,

the unit

must

be stopped and

disconnected

from line power

.

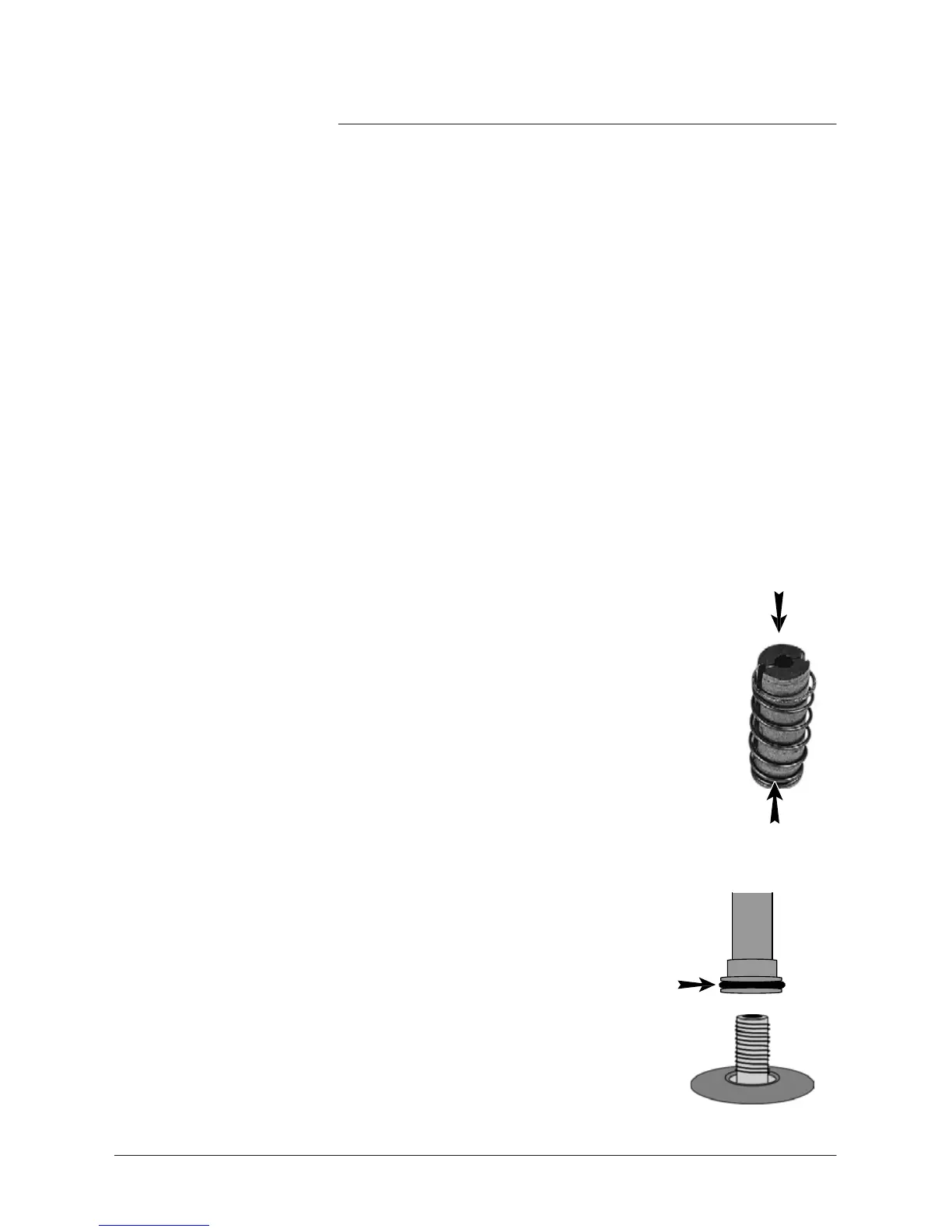

If ”piston” O-rings are installed on the valve,

use

a

gasket

extractor to

remove

it.

Take

care not to damage the sealing surface.

Immediately

protect the valve inlet if it is to stay open for a long time.

Cleaning

Clean the

surfaces

of the different

parts

with

alcohol.

For the Normally Open type Minisol

valves

(NO),

O-rings are

present

on both

sides

of the valve.

Improve

the cleaning by blowing off the

parts

with

dry filtered air, particularly the O-ring grooves.

4

/6

Seal

preparation

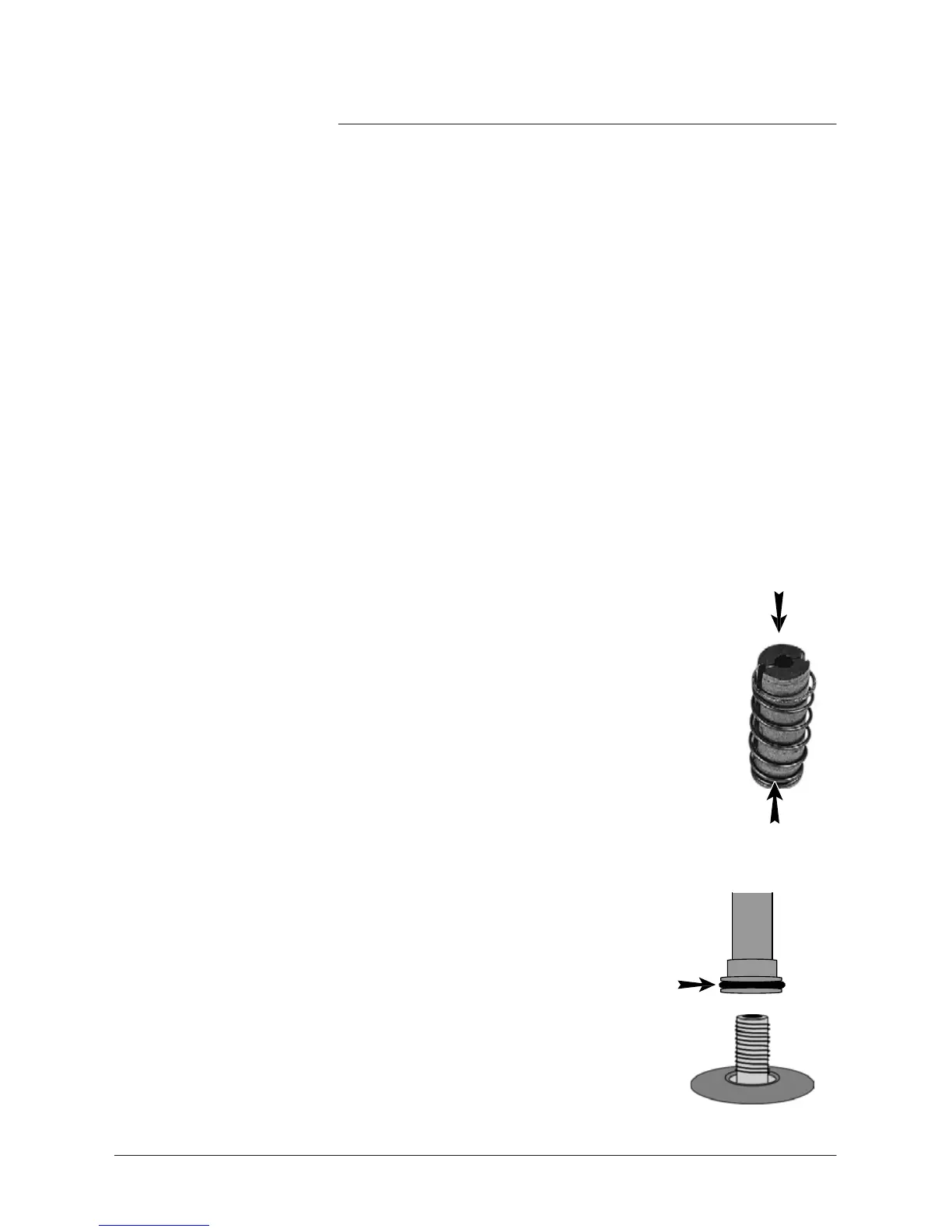

Place

the ”piston” O-rings.

A slight greasing of

these

rings is possible.

Grease quantity should be limited to avoid

helium

retention

and make

assembly

easier.

Put

a drop of grease on

your fore-finger.

Spread the grease out between your

thumb and fore-finger.

Lay

the grease on the ring by turning it

between your fingers.

The

ring should have a shiny

aspect

with

no excess.

Loading...

Loading...