MM-400A

8. Operation Screens

8-82

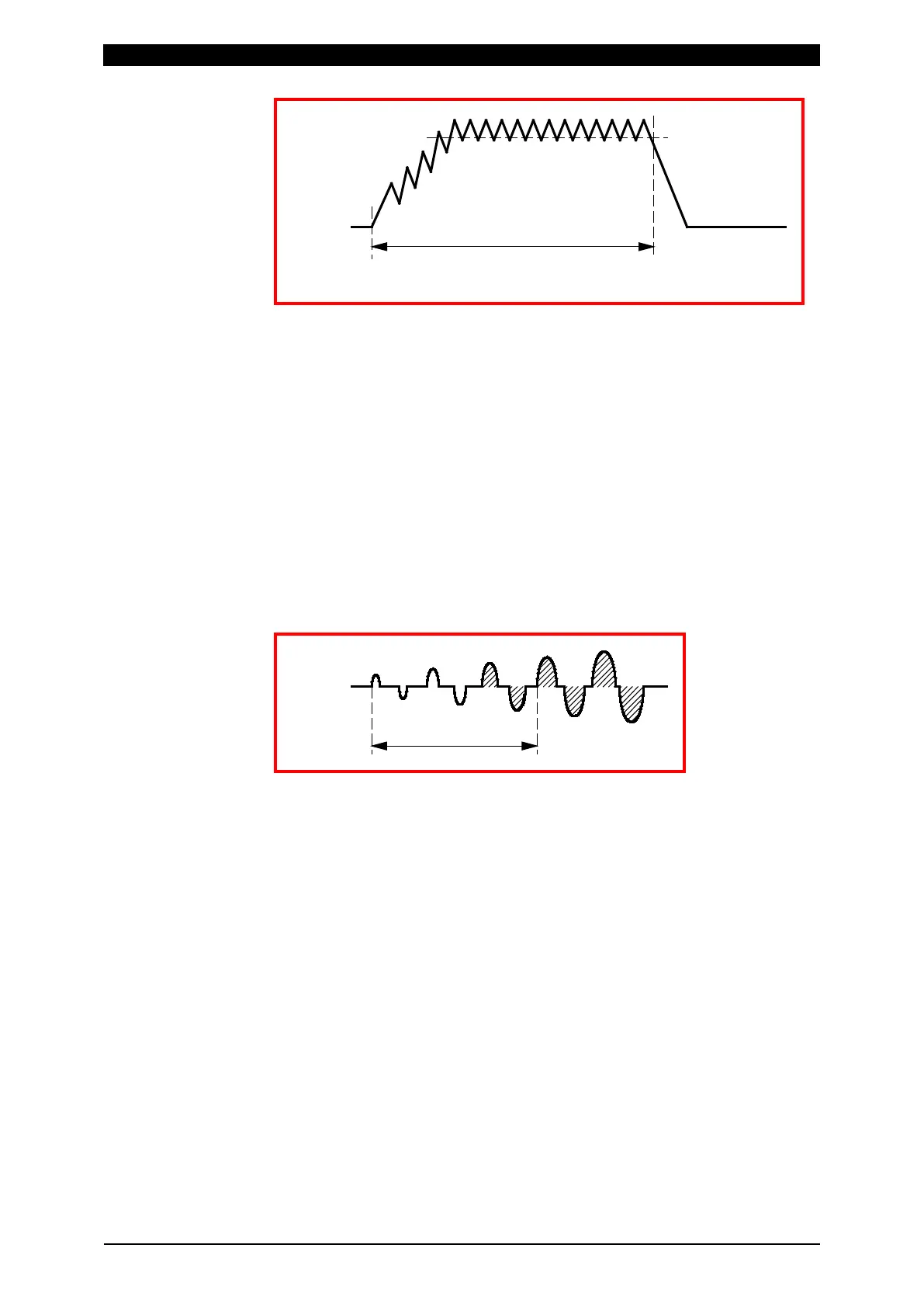

(7) MEASUREMENT MIN TIME

In the early steps of current flow, the instrument may fail to measure the

current if the current is excessively low. (This likely occurs if the upslope is

used.) In such a case, set a forced measurement time. Set a forced

measurement time in the following ranges.

When the TRIGGER and TIME settings are changed, MEASUREMENT MIN

TIME may be initialized. Set MEASUREMENT MIN TIME again. (Refer to "l-1.

BASIC SETUP (1) Screen.")

• When CYC-AC, CYC-DC, LONG CYC-AC or CYC***Hz-AC is selected for

TIME: 00.5 to 50.0 CYC

• When ms-DC or ms-AC is selected for TIME: 0001 to 1,000 ms

• When SHORT ms-DC is selected for TIME: 000.1 to 100.0 ms

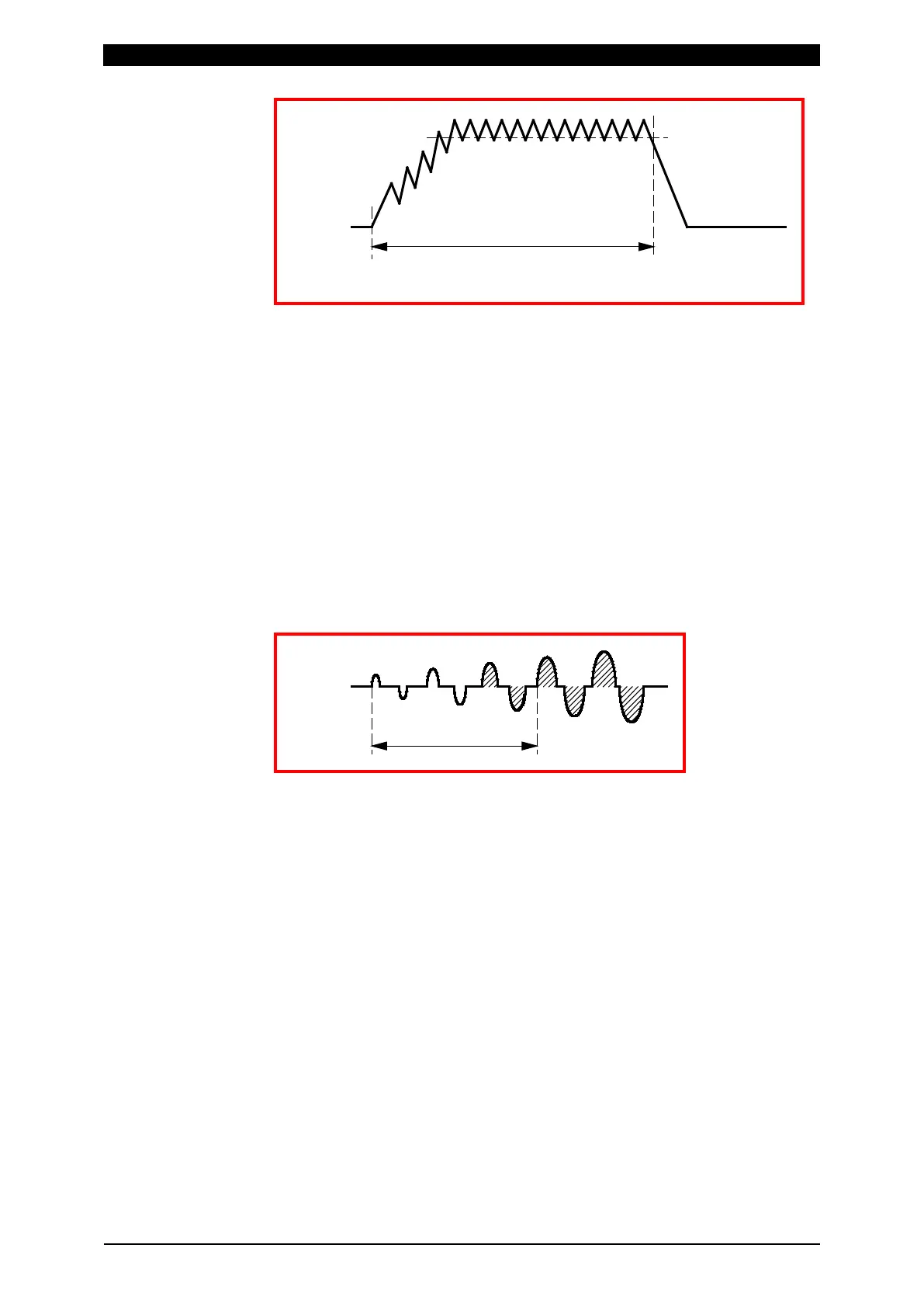

Set a time so that currents of measurable magnitude (shaded areas in the

figure) are included.

(8) MEAS INHIBIT TIME

Set a measurement prohibition time (0.0 to 10.0 sec). Select SET PULSE for

PULSE MODE, and “00” for PULSE No.

By setting a measurement prohibition time, a non-measurement time following

a measurement is provided not to measure a reset current following a welding

current flow peculiar to a capacitor-type welding machine.

(9) END LEVEL

You can measure the current flow time till the Current End Level setting is

reached. Set the Current End Level as the ratio to the used current range (1.5

to 15.0%).

Refer to (Note 1) Difference between the original measurement mode and the

ISO17657-compliant measurement mode for RMS calculation in “c. VIEW

Screen.”

(10) PULSE 2 TRIG LEVEL

When you have selected NO COOL for PULSE MODE, this can be set. The

instrument starts measurement determining the point in time where the start

current is exceeded as the measurement start point. Measurement is possible

only if the current at the second step is larger than that at the first step.

Current

FALL LEVEL

Current flow time

(Time till it falls below FALL LEVEL)

Current

Forced measurement time

Loading...

Loading...