Appendix 4 - BST eltromat STB 1 Connections

D

CLS Pro 600 – Line and Contrast Sensor 105/108

Using Wiring Sleeves:

The crimping is also gas-tight (no cross crimping) i.e. there is no

gap between the conductor and the wiring sleeve. We recom-

mend using VarioCrimp-4-Zange 206-204 crimping pliers made by

WAGO. The length of the metal sleeves fitted on the wiring sleeve

must be at least 8 mm.

Using Cable Without Wiring Sleeves:

For fine and multi-core cable and for fine-wired cable, whose kink

resistance is not sufficient due to its small diameter, in order to

overcome the contact force of the clamping springs, the clamp

must be correctly opened using a screwdriver.

Check that all the cables are fitted tightly after the connections

have been made (in both cases).

D1 Installation Instructions For EMC-Wiring

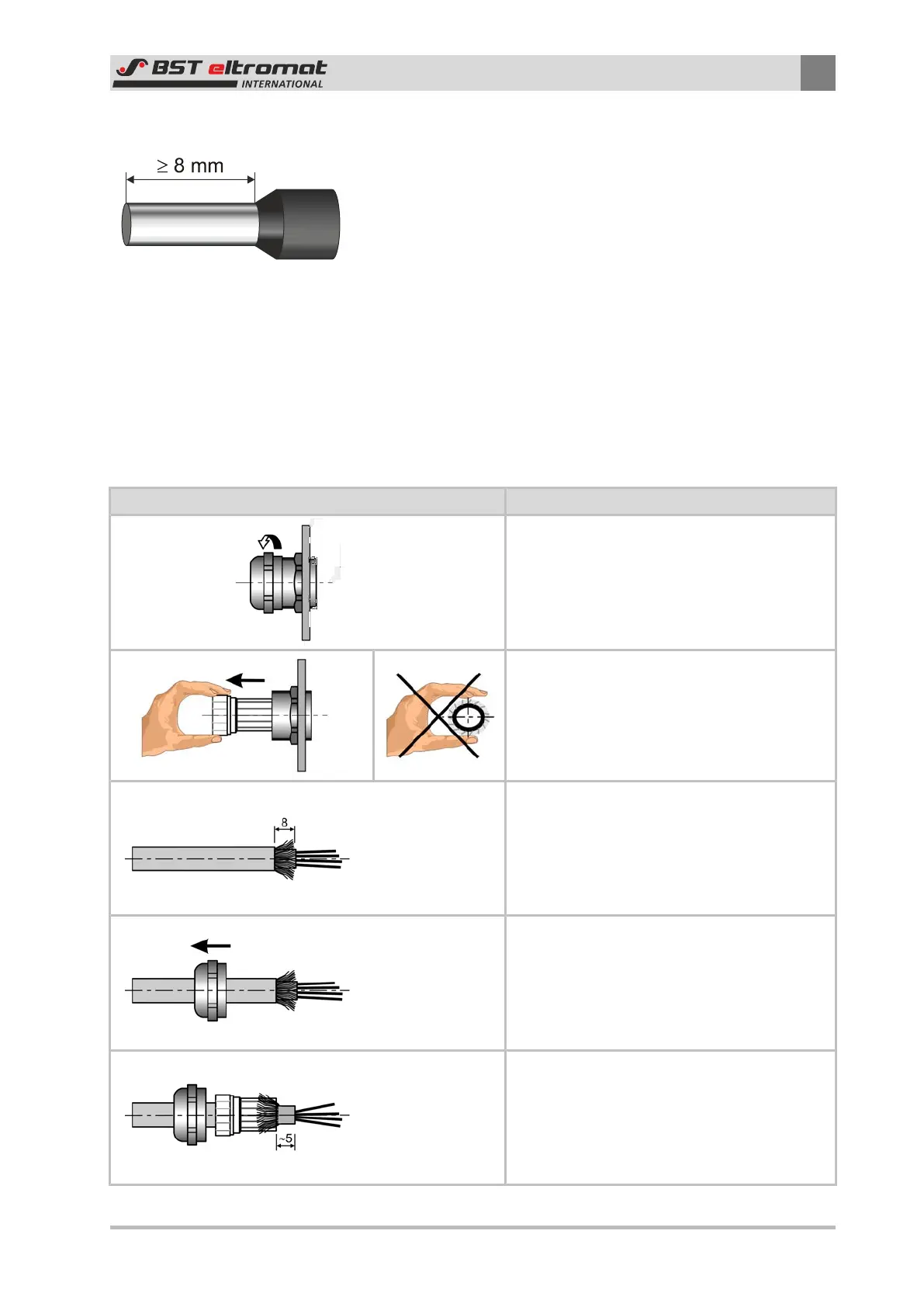

Figure Wiring step

►

Unscrew the union nut on the cable gland.

►

Pull out the clamping insert from interme-

diate support.

Attention! When pulling out the clamping

insert, do not bend it (do not press too

hard).

►

Strip cable back by 8mm so that the screen

braiding is uncovered.

►

Pull the union nut onto the cable.

►

Feed the cable into the clamping insert and

bend the screen braiding back over the

clamping insert.

Loading...

Loading...