140 Functional Description CG Drives & Automation, 01-5326-01r5

Flux Optimization [354]

Asynchronous motors

Flux Optimization for asynchronous motors reduces the

energy consumption and the motor noise, at low or no load

conditions. Flux Optimization automatically decreases the

V/Hz ratio, depending on the actual load of the motor when

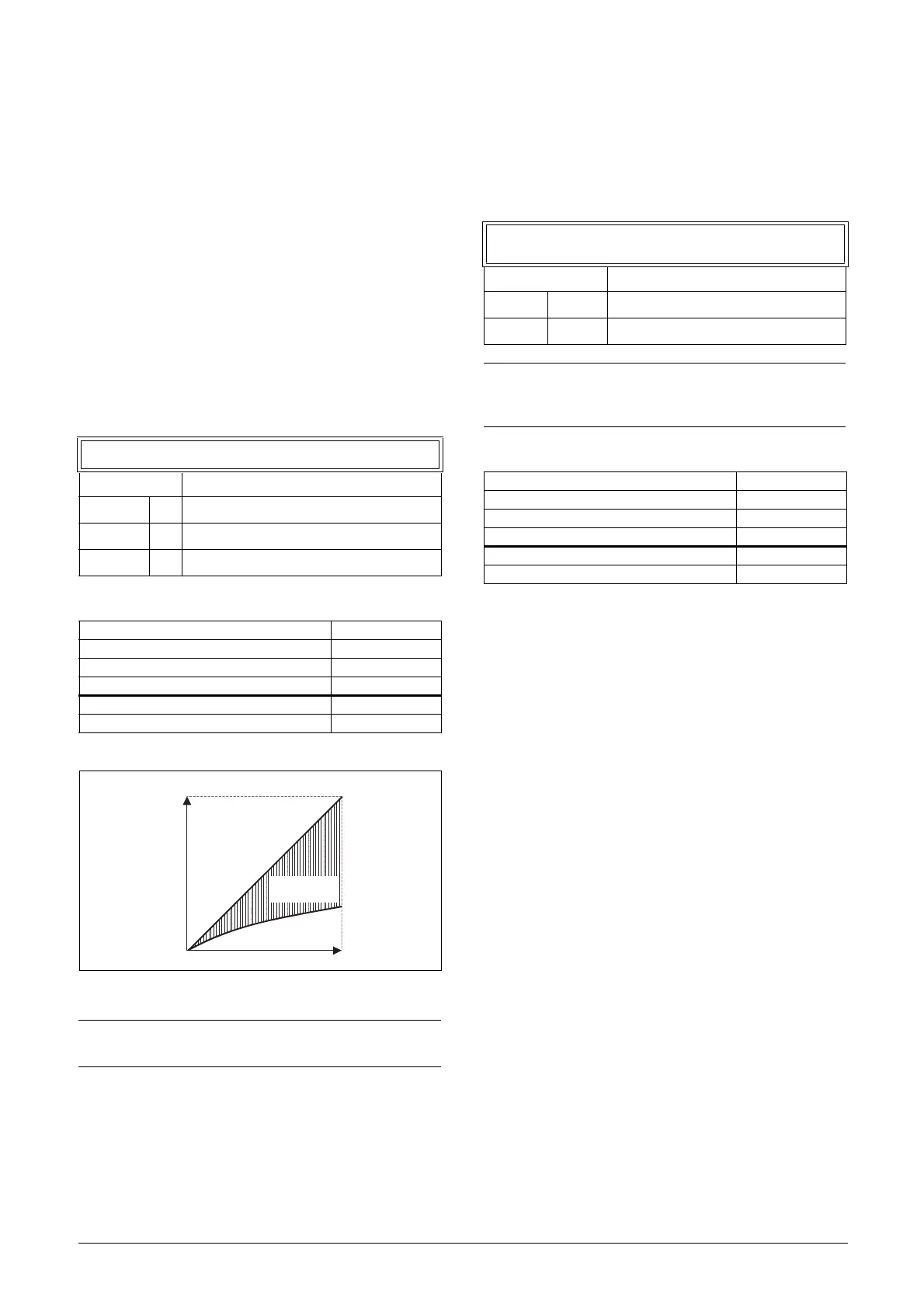

the process is in a steady state. Fig. 109 shows the area

within which the Flux Optimization is active.

Permanent magnet synchronous and

synchronous reluctance motors

Flux optimization for permanent magnet synchronous

motors and synchronous reluctance motors adjusts the

V/Hz ratio, to either minimize the current or by predicting a

suitable level based on the torque (and speed). Note that

IxR compensation is needed for synchronous motors to get a

good start, also when flux optimization is activated.

Communication information

Fig. 109 Flux Optimizing

Maximum power [355]

Sets maximum power. Can be used for limiting motor

power in field weakening operation. This function operates

as an upper power limit and internally limits the parameter

“Max Torque [351]” according to :

Tlimit = Plimit[%] / (Actual Speed / Sync Speed)

Communication information

354 Flux optim

Default: Off

Off 0 Function disabled

On(lmin) 1 Flux controlled to minimize current

On 2 Flux adjusted based on the torque

Modbus Instance no/DeviceNet no: 43144

Profibus slot/index 169/48

EtherCAT and CANopen index (hex) 4c48

Profinet IO index 19528

Fieldbus format UInt

Modbus format UInt

NOTE: Flux optimization works best at stable

situations in slow changing processes.

355 Max Power

Default: Off

Off 0 Off. No power limit

1 - 400 1 - 400 1 - 400% of motor nominal power

NOTE: The maximum possible setting for parameter

[355] is limited by I

NOM

/I

MOT

x 120%, but not higher

than 400%.

Modbus Instance no/DeviceNet no: 43145

Profibus slot/index 169/49

EtherCAT and CANopen index (hex) 4c49

Profinet IO index 19529

Fieldbus format Long, 1=1%

Modbus format EInt

Loading...

Loading...