CTH200 Series PLC User Manual

The number of motion control module is only internally unified. If the PLC has 3

modules, among which module 0 and 2 is the motion control module, module 1 is not,

then module 0 is ID0, module 1 is uncontrollable for it is not motion control module,

and module 2 is ID1.

If a single motion control module is attached behind the CPU, the delay from enable

to execution of the output instruction is about 780us due to transmission delay. If

there are up to 5 motion control modules hanging behind the CPU, the delay is about

930us.

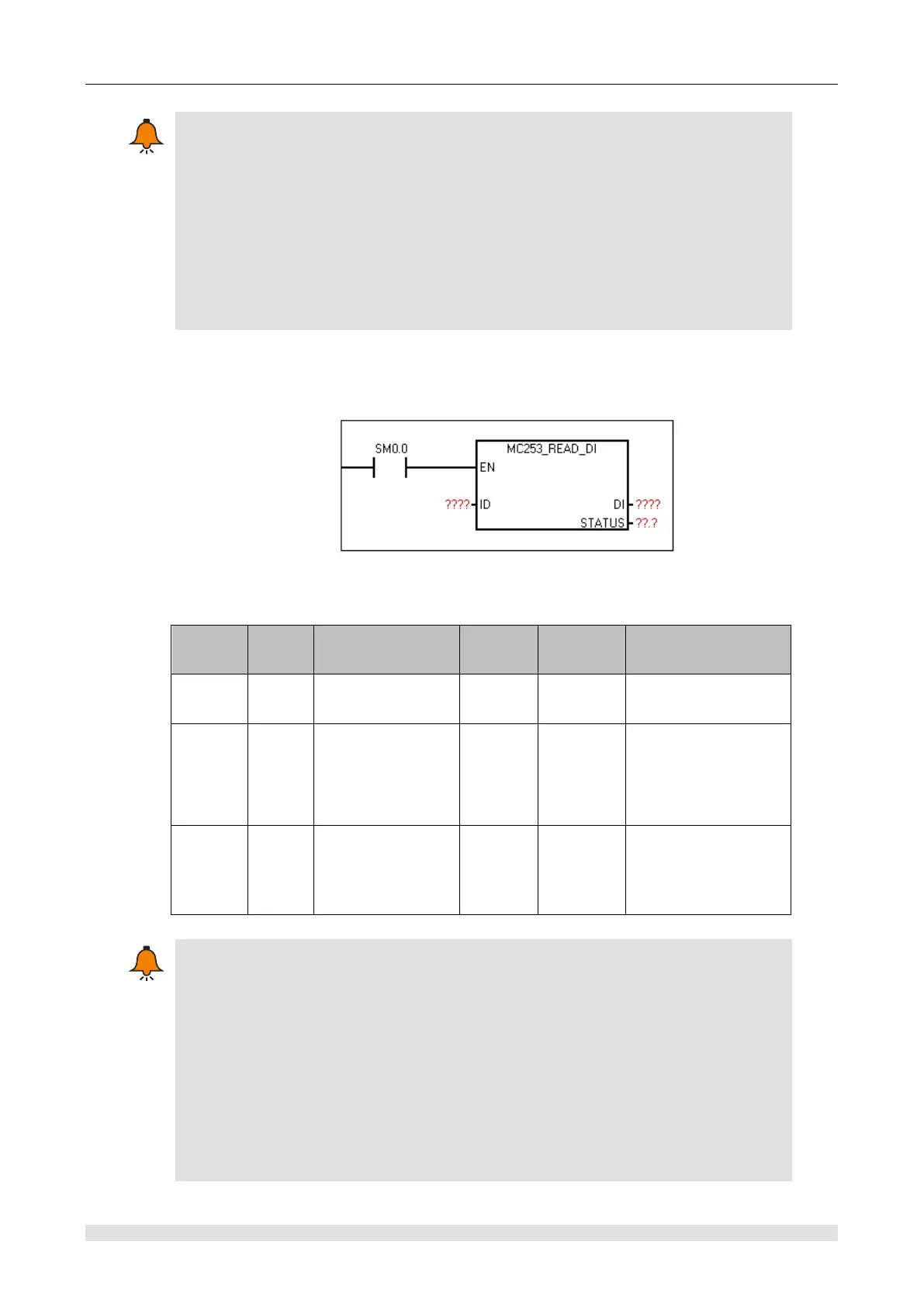

Read modules input status instruction

① Function name: MC253_READ_DI

② Function: Read input of motion control module

③ Parameter

Motion control

module ID number

Apply only to motion

control module

DI corresponds to 8 I

input, low byte

corresponds to I low

bit, such as DI bit0

corresponds to I0.0

Communication

status sign

The number of motion control module is only internally unified. If the PLC has 3

modules, among which module 0 and 2 is the motion control module, module 1 is not,

then module 0 is ID0, module 1 is uncontrollable for it is not motion control module,

and module 2 is ID1.

When an axis call motion control instruction, if confirm to operating conditions, the

running process of the axis port output pulse or direction according to the instruction

(corresponding port is not controlled by the MC253_DO_CTRL), the port can restore

normal IO functions after run (accept instruction MC253_DO_CTRL control); use

instruction MC253_DO_CTRL carefully so as not to affect the use of motion control.

Loading...

Loading...