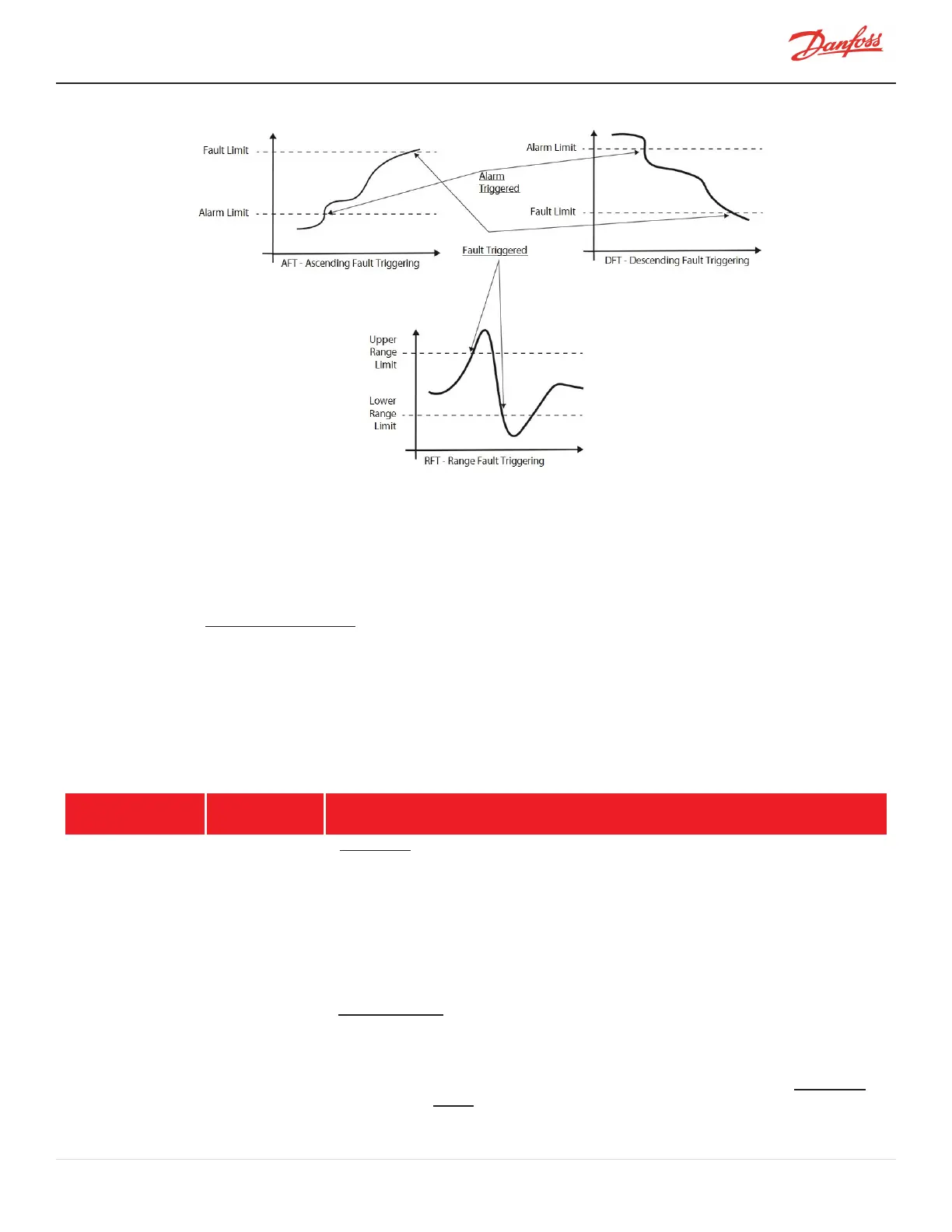

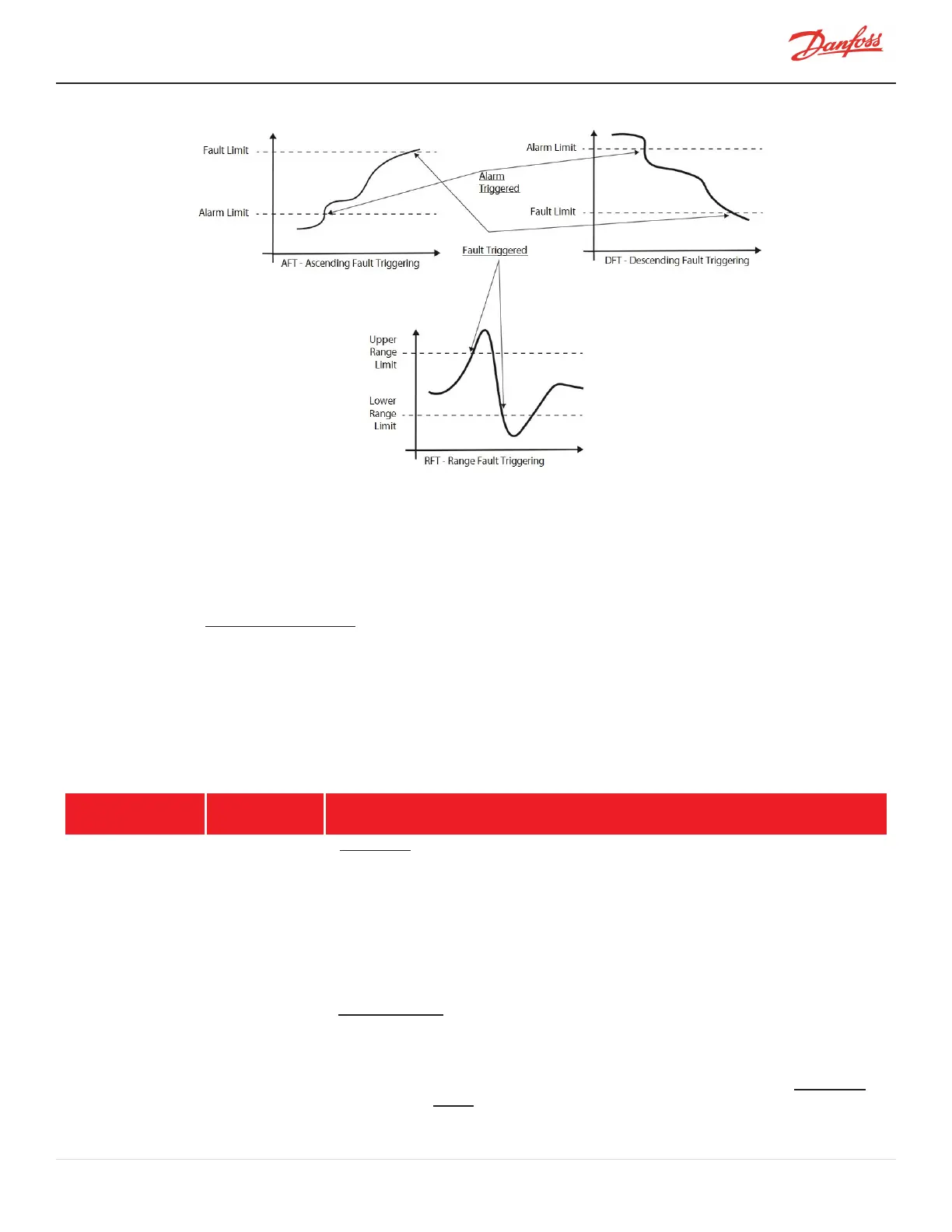

Figure 5-1 Fault Trigger Methods

Fault Reset:Afaultthatdoesnotrequireapowercycletoclear(non-critical)canberesetinthefollowingmanner:

Interlockmustbeclosed,settheDemandto"0"andafterwardstoavaluegreaterthan0.Nowthefaultisresetand

thecompressorisreadytorun.Theassumptionisthatthecauseofthefaulthasbeenrectified.

TheClearFaultsbuttonintheSMTCompressorMonitorcanbeusedinsoftwareversions4.0.0andlater.Alsoseethe

OEMProgrammingGuideforadditionalfaultresetoptions.

Afaultdemandingapowercycle(Lock-OutFault)isresettablebycyclingthemainspowertothecompressor.The

assumptionisthatthecauseofthefaulthasbeenrectified.Refertothefollowingtables:

l

Table5-6CompressorStatus

l

Table5-8Motor/SystemStatusonpage260

l

Table5-9BearingStatusonpage263

Table 5-6 Compressor Status

Compressor Status

Description

Trigger Method Troubleshooting

HighInverter

TemperatureFault

AFT Consequence:

l

IndicatestheInvertercoolingisinsufficient.Repeatedoccurrencesofthisalarmcan

resultinInverterfailure.

l

Ifthisfaultoccursthree(3)timeswithina30-minuteperiod,aLock-OutFaultwilloccur.

l

ThemeasuredInvertertemperaturemustdropbelowtheMaximumDriveStartup

Temperaturebeforearestartcanbeattempted,otherwisetheCompressorMonitorTool

ControlStatusmessage“Abovedrivetemperaturelimitwaitingtocooldown”willbe

displayed.

Recommendation:

l

Ensuretheliquidmotor-coolinglinehassufficientliquidsupplyandisnotblocked.

l

Preventprolongedoperationatapressureratiolessthan1.5.

o

LowLiftoperationrequiresadditionalconsiderations,refertotheApplications

Manual

l

Verifythesolenoidsareoperationalandnotblocked.RefertoSection4.6.3Solenoid

M-SV-001-EN Rev. H-1/23/2023 Page 255 of 294

Loading...

Loading...