94

12.3 Statistic

If the command "statistic" is used in the screwing program then in the sequence controller

AST11 a statistic is kept about the last 100 values for the respective program.

The following values are calculated for moment and angle:

• Mean value

• Standard deviation absolute

• Standard deviation percentages, based on mean value

• CP value / CPK value

The limits for the Cp/CPK value calculation can be entered. If no limits are set then the

calculation is done automatically with ±15 % of the mean value. The limits entered are

maintained even after switching off the sequence controller AST11.

The statistic can be displayed via the sequence controller AST11 as well as via the web

interface (also see 8.2.5.2.2

Statistics and 8.3.4.5 Process Data Statistics). The statistic

can be deleted for individual programs or completely for all programs.

The statistic is deleted when the sequence controller AST11 is switched off.

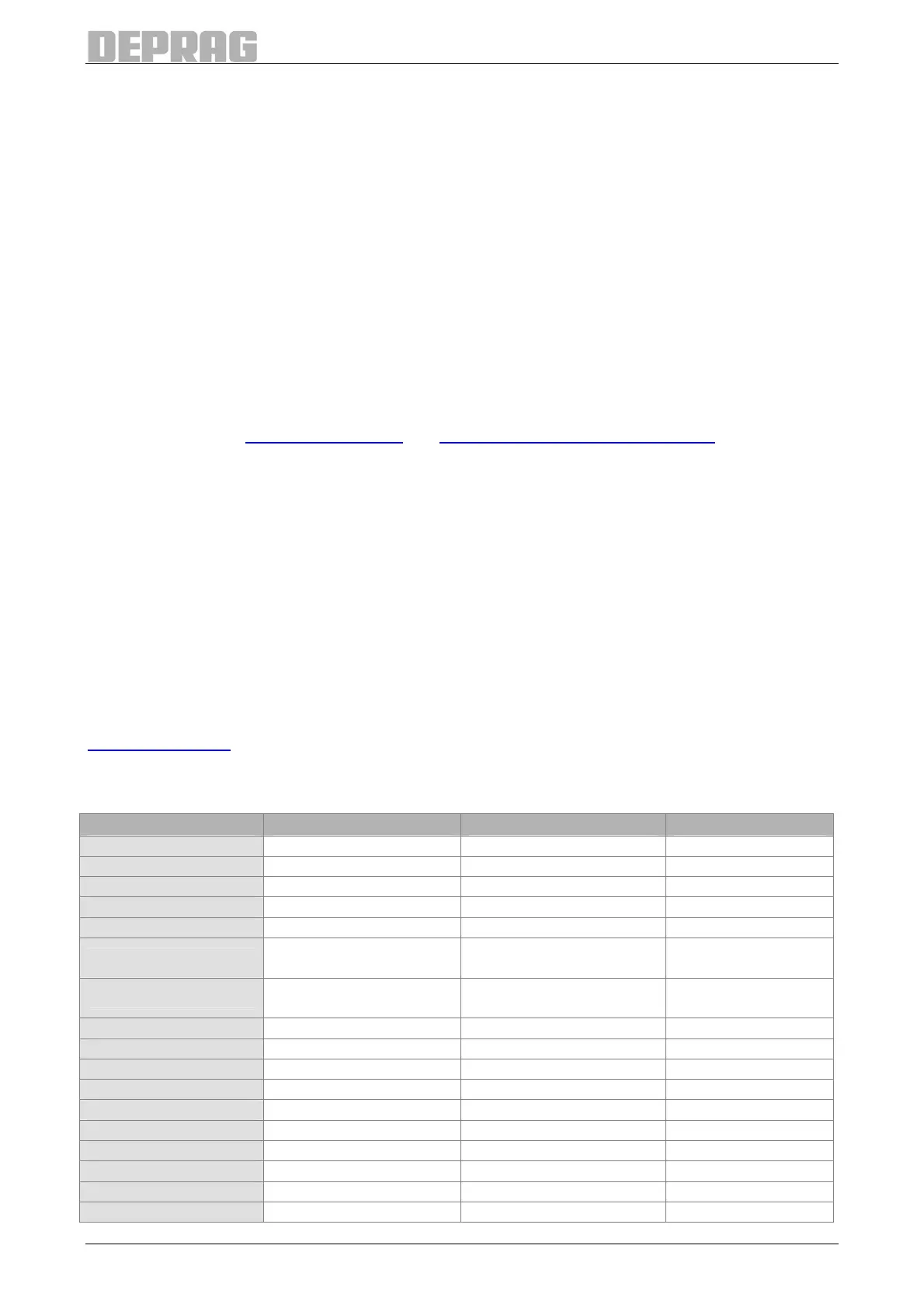

12.4 Print output

Data can be printed out in ASCII format via the serial data port of the AST40. The sum-

mary of the required values employs a format string template.

A format string can be summarized using random text and specified commands, whereby

texts can be output directly to the printer and commands can be replaced by the respective

valid value (see following table).

A command consisting of @ characters and ending with a blank character are shown for

this.

Changing the format string is only possible via the web-based user interface (see

8.3.4.12.1 Printer). The print output is activated by the command "Print" during the screw-

driving process. Results of NOK screwdriving processes are always printed out.

The following commands are available:

Command Output value Output format Example

date_euro Date in Euro-format Day.Month.Year 24.04.20013

date_usa Date in US format Month/Day/Year 04/24/20013

date_iso Date in ISO format Year-Month-Day 20013-04-24

time Time Hour:Minute:Second 7:13:37 AM

step Step number Value 3

torque

End torque Measuring

system 1

Value unit 0,215 Nm

angle

Angle measuring sys-

tem 1

Value unit 1080 °

prog Program number Value 1

errornum Status / Error number Value 0

errortext Status / Error text Error message torque underrun

runtime Running time Value unit 0.5 s

torquetarget Torque target value Value unit 0.200 Nm

torqueLL Torque lower limit Value unit 0,000 Nm

torqueUL Torque upper limit Value unit 0,350 Nm

angletarget Angle target value Value unit 1080 degrees

angleLL Angle lower limit Value unit 1000 degrees

angleUL Angle upper limit Value unit 1150 degrees

Loading...

Loading...