5-7

95-8533

18.2

DEVICE CALIBRATION LOGS

AND RECORDS

The DCU keeps a calibration log in non-volatile

memory that can be used by the operator to

evaluate the remaining life of some sensors.

This log includes the zero, span, date and

time for each successful calibration. An

aborted calibration is indicated by zeros in the

zero and span values. The calibration log is

cleared when the sensor replacement switch

is pressed and the calibration is successfully

completed.

The initial calibration is logged in position

one, where it remains for the life of the

sensor. If more than eight calibrations are

performed without the sensor replacement

switch being pressed, the newest calibration

data will replace the second oldest so that

the initial calibration data can be saved. The

old calibration data will be lost. This feature

enables sensor sensitivity trending to aid in

maintenance or troubleshooting.

The analog value for the sensor is represented

in raw analog-to-digital counts 0 to 4095,

where 0 represents 0 ma and 4095 represents

24 mA.

TROUBLESHOOTING

Tables 5-1 and 5-2 are provided to assist in

locating the source of a system problem.

REPLACEMENT PARTS

Eagle Quantum Premier devices are not

designed to be repaired in the field. If a

problem should develop, first carefully

check for proper wiring, programming and

calibration. If it is determined that the problem

is caused by an electronic defect, the device

must be returned to the factory for repair.

NOTE

When replacing a device, be sure that

all rocker switches on the replacement

are set the same as the original device.

Consult the settings documented

during system installation and setup to

determine proper settings for the new

device. Remove power before removing

a device or plugging in a replacement

unit. When a device is replaced,

conguration is done automatically.

DEVICE REPAIR AND

RETURN

Prior to returning devices or components,

contact the nearest local Detector Electronics

office so that a Service Order number can be

assigned. A written statement describing the

malfunction must accompany the returned

device or component to expedite finding the

cause of the failure.

Pack the unit or component properly. Use

sufficient packing material in addition to an

antistatic bag or aluminum-backed cardboard

as protection from electrostatic discharge.

Return all equipment transportation prepaid to

the factory in Minneapolis.

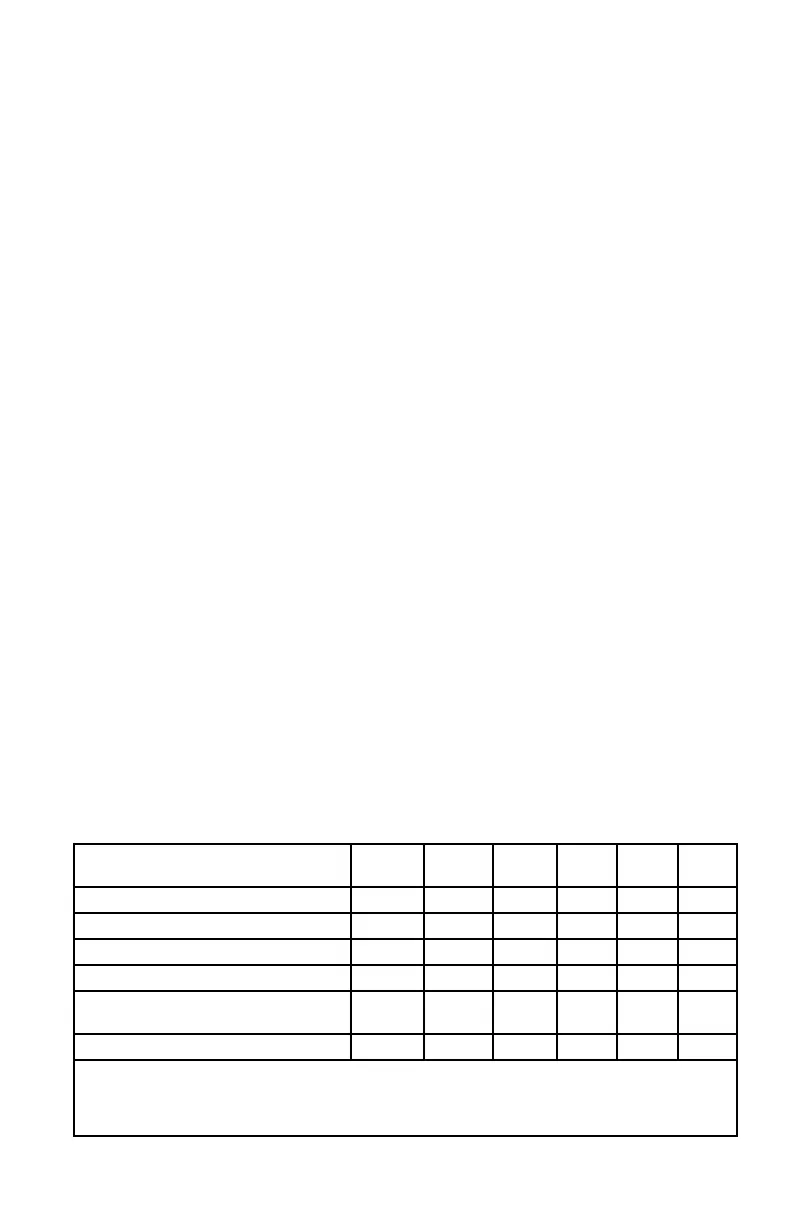

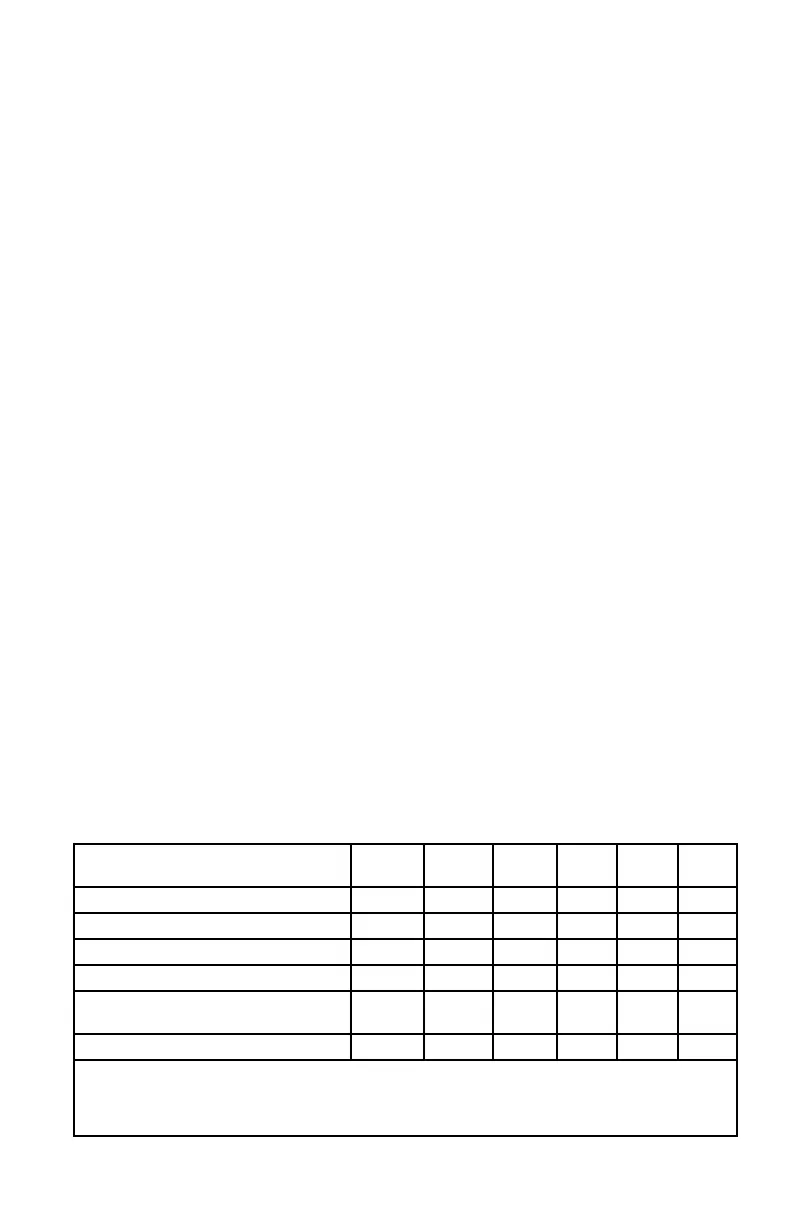

Table 5-1—Troubleshooting Guide - DCIO Module

I/O Type

Normal

(Off)

Normal

(On)

Open

(Off)

Open

(On)

Short

(Off)

Short

(On)

Unsupervised Input –15.4 0 –15.4 –15.4 0 0

Supervised Input (EOL Resistor) –14.4 0 –15.4 –15.4 0 0

Supervised Input (EOL/Inline Resistors) –15.4 –15 –15.4 –15.4 0 0

Unsupervised Output –15.4 23.9 –15.4 23.9 0 0

Supervised Output (Agent Release)

0 to 2.1

Note 2

23.9 –15.4 23.9 0 0

Supervised Output (Notification) –14.4 23.9 –15.4 23.9 0 0

Notes:

1. All measurements are in Volts and are measured in reference to the common terminal and 24.0 Vdc is the

module’s input.

2. Value is dependent on the resistance of the solenoid attached.

Loading...

Loading...