3-42

95-8533

18.2

Det-Tronics S

³

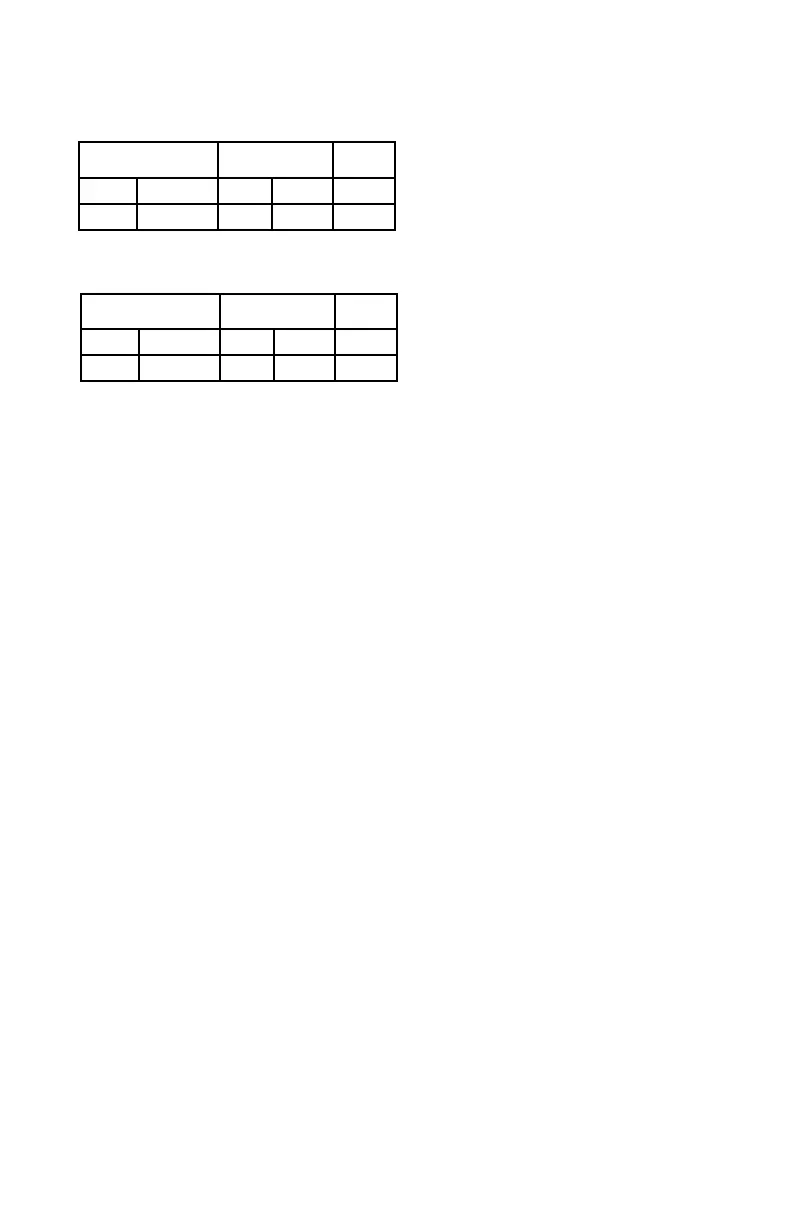

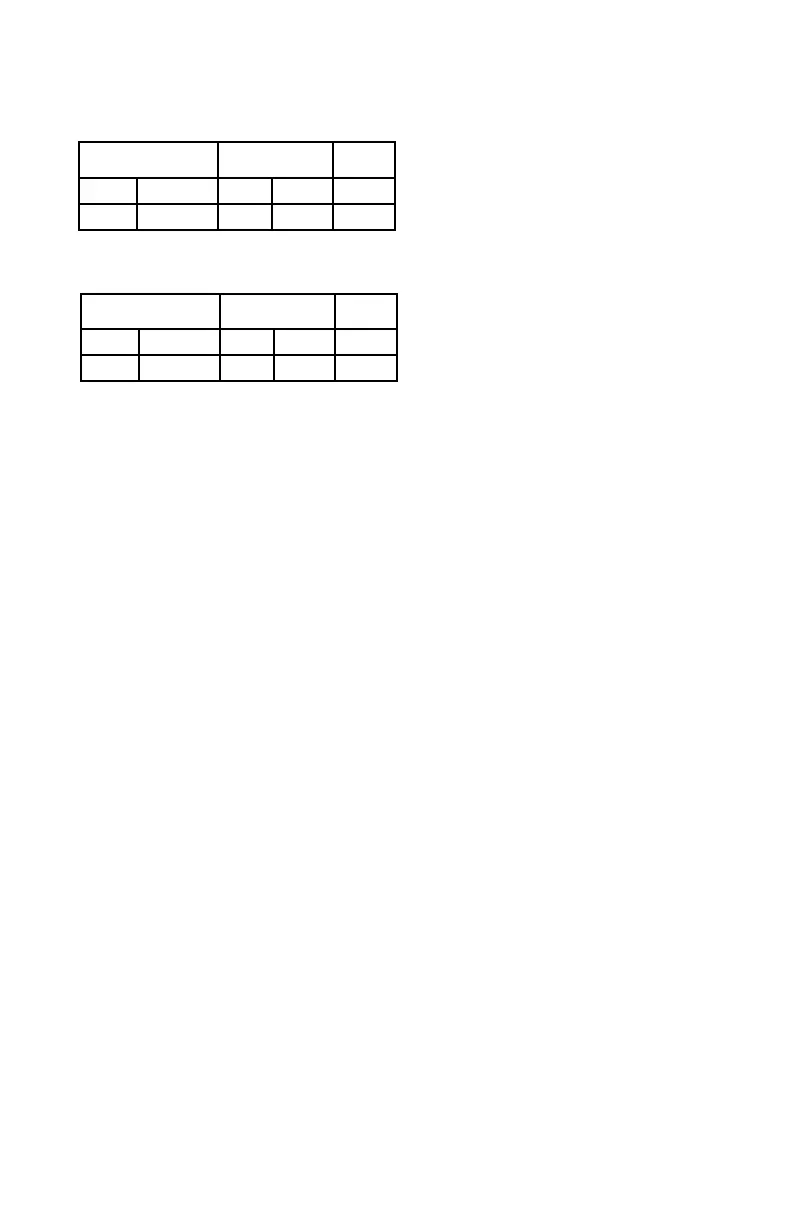

Safety System Software is used

for device configuration. The following tables

show the minimum software/firmware releases:

GAS DETECTOR LOCATION

AND INSTALLATION

Gas detection devices must be properly

located to provide maximum protection.

Determining the proper number of devices and

placement varies depending on the specific

requirements of the area of protection.

The following should be considered when

locating a gas detection device:

1. Gas type. If it is lighter than air (acetylene,

hydrogen, methane, etc.), place the

sensor above the potential source. Place

the sensor close to the floor for gases that

are heavier than air (benzene, butane,

butylene, propane, hexane, pentane, etc.)

or for vapors resulting from flammable liquid

spills.

NOTE

Air currents can cause a gas that is

heavier than air to rise. Also, if the gas is

hotter than ambient air, it could also rise.

2. How rapidly will the gas diffuse into the air?

Select a location for the sensor as close as

possible to the anticipated source of a gas

leak.

3. Ventilation characteristics. Air movement

will cause gas to accumulate more heavily

in one area than another. The devices

should be placed in areas where the

most concentrated accumulation of gas is

anticipated.

4. Devices should be pointed down to prevent

the buildup of moisture or contaminants on

the filter.

5. Devices must be accessible for testing and

calibration.

NOTE

The use of the Sensor Separation Kit will

be required in some installations.

ENVIRONMENTS AND SUBSTANCES

THAT AFFECT GAS DETECTOR

PERFORMANCE

Catalytic sensors should be located where

they are safe from potential sources of

contamination that can cause a decrease in

the sensitivity of the device including:

A. Substances that can clog the pores of the

flame arrestor and reduce the gas diffusion

rate to the sensor including:

Dirt and oil, corrosive substances such as

Cl2 (Chlorine) or HCl, paint overspray, or

residue from cleaning solutions that can

clog the flame arrestor.

NOTE

A dust cover should be installed to

protect the flame arrester whenever

these conditions exist.

B. Substances that cover or tie up the active

sites on the catalytic surface of the active

sensing element such as volatile metal

organics, gases, or vapors of hydrides,

and volatile compounds containing

phosphorous, boron, silicone, etc.

Examples:

RTV silicone sealants

Silicone oils and greases

Tetraethyl lead

Phosphine

Diborane

Silane

Trimethyl chlorsilane

Hydrogen fluoride

Boron trifluoride

*for part number 007606-002

For Gas Applications

Controller Firmware* AIM S

³

Rev. Version Rev. Version Version

B 3.06 B 1.02 2.9.1.1

*for part number 008983-001

For Flame Applications

Controller Firmware* AIM S

³

Rev. Version Rev. Version Version

C 5.52 D 1.07 4.0.0.0

Loading...

Loading...