95-8533

5-2

18.2

NOTE

Electrochemical sensors have a finite

lifespan. If a successful calibration

cannot be performed, inspect the

hydrophobic lter. If the lter is plugged,

replace it and recalibrate the sensor. If

the filter is in good condition, replace

the sensor. Recalibrate following the

procedure described in the “Calibration”

section.

CALIBRATION AND

ADJUSTMENTS

To ensure optimum performance, calibration

must be performed on a regularly scheduled

basis. Since each application is different, the

length of time between regularly scheduled

recalibrations can vary from one installation

to the next. In general, the more frequently a

system is checked, the greater the reliability.

IMPORTANT

4–20 mA devices not manufactured by

Det-Tronics must be pre-calibrated. To

ensure adequate protection, calibration

must be performed on a regularly

scheduled basis.

NOTE

If the calibration procedure is not

completed within 12 minutes, the

detector will revert back to the previous

calibration values. The red LED will blink.

The calibration will be logged as aborted.

NOTE

The “Sensor Replacement” calibration

procedure must be used for the initial

calibration of a new sensor. The “Routine

Calibration” procedure can be used for

all subsequent calibrations.

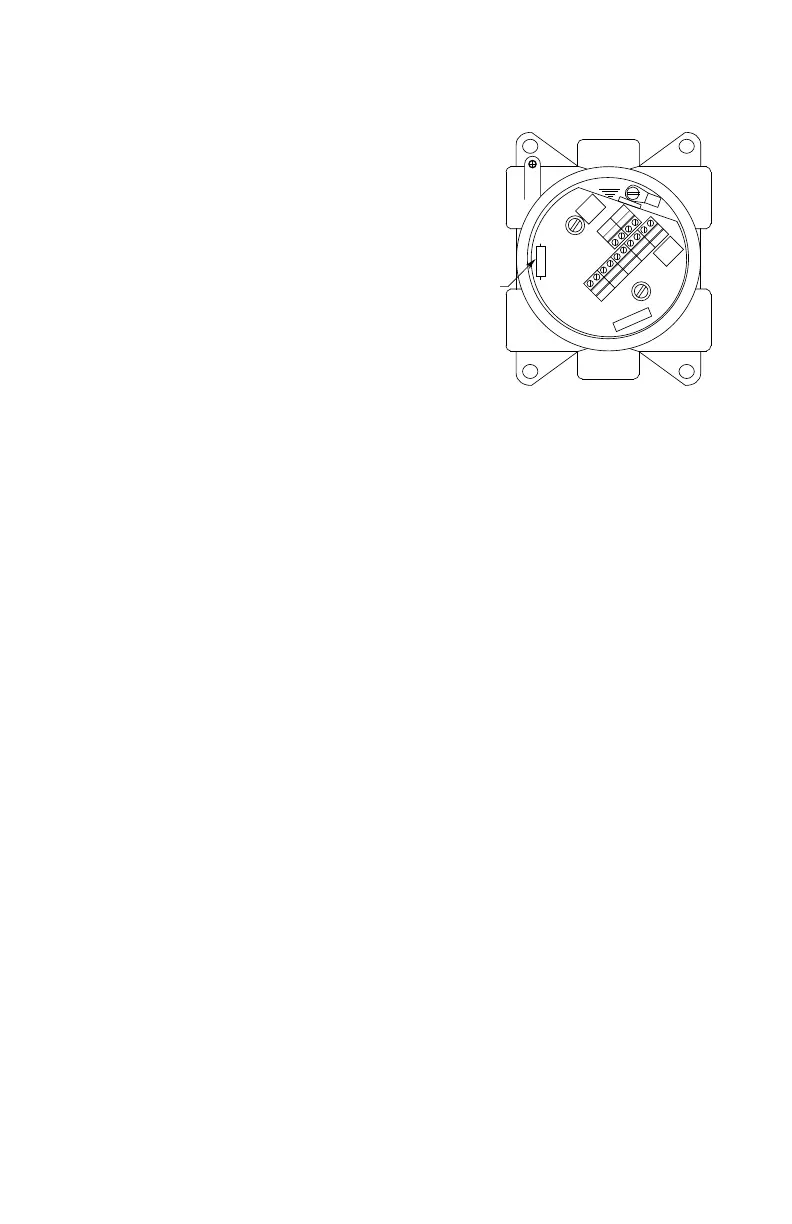

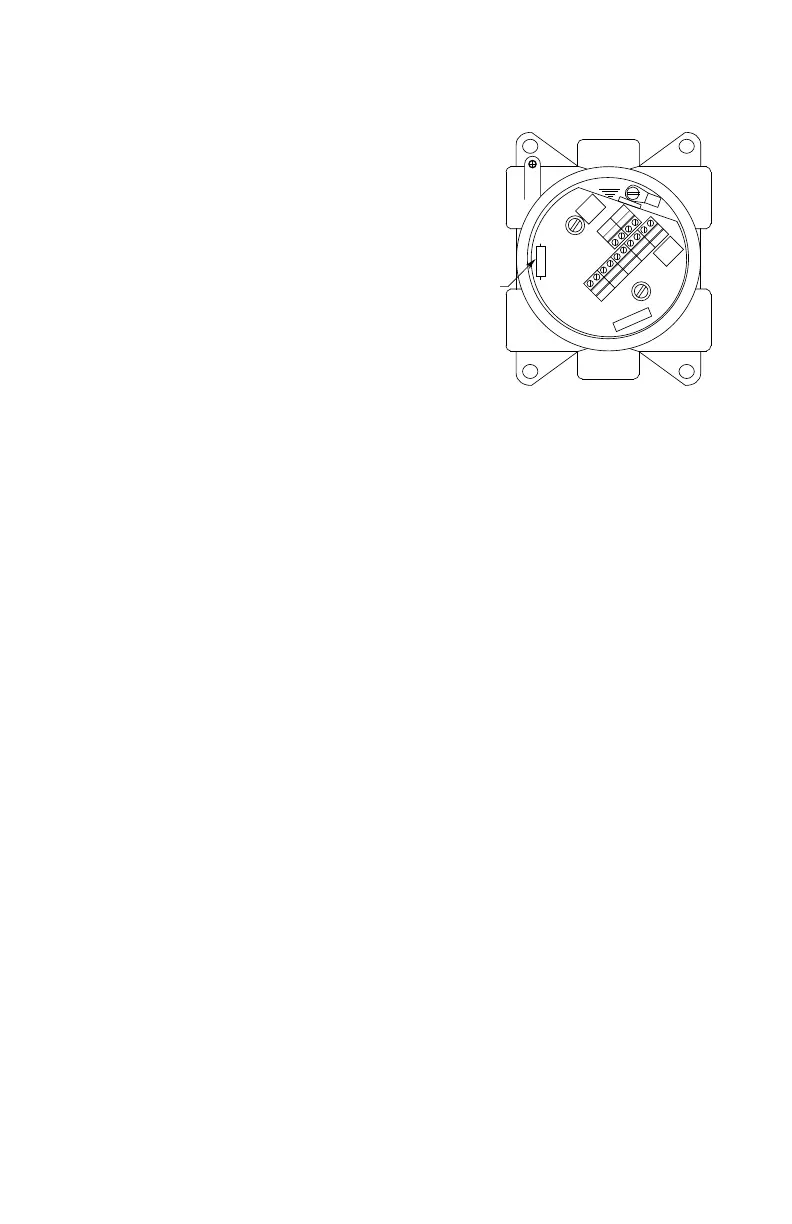

NOTE

Some calibration procedures require

the operator to activate the reed switch

located on a circuit board inside the

junction box. See Figure 5-1 for reed

switch location. To activate the switch,

hold the calibration magnet against the

side of the junction box near the switch

location approximately one inch above

the mounting surface. (Do not open

the junction box.) Hold the calibration

magnet in place for approximately

four seconds to initiate the calibration

procedure.

CALIBRATION ALGORITHM A

FOR MANUAL CALIBRATION OF

UNIVERSAL DCU

Normal Calibration

1. Activate the reed switch. (The red LED

blinks while the reed switch is closed.)

2. After the reed switch has been closed for

three seconds, the calibrate LED blinks,

indicating it is ready for the zero input.

3. Enter the zero input (4 mA).

4. Activate the reed switch. (The red LED

blinks while the switch is closed.)

5. After the reed switch has been closed

for three seconds, the communication

module records the uncalibrated value

in the calibration log and calibrates the

zero value. (The calibrate LED stays on

steady.)

6. Apply the calibration gas.

7. The calibrate LED blinks as the input

increases.

8. Activate the reed switch. (The red LED

blinks while the reed switch is closed.)

9. The communication module records the

uncalibrated value in the calibration log

and calibrates the span value after the reed

switch is on for three seconds.

10. The calibrate LED stays on steady.

GND

9 107 85 63 41 2

13 1411 12

A188

MAGNETIC REED SWITCH *

*

TO ACTIVATE THE MAGNETIC REED SWITCH,

HOLD THE CALIBRATION MAGNET AGAINST THE SIDE OF THE ENCLOSURE

AT THE LOCATION OF THE REED SWITCH,

APPROXIMATELY ONE INCH ABOVE THE MOUNTING SURFACE.

SW1

Figure 5-1—

DCU Terminal Wiring Board Mounted in Six-Port Junction Box

Loading...

Loading...