3-48

95-8533

18.2

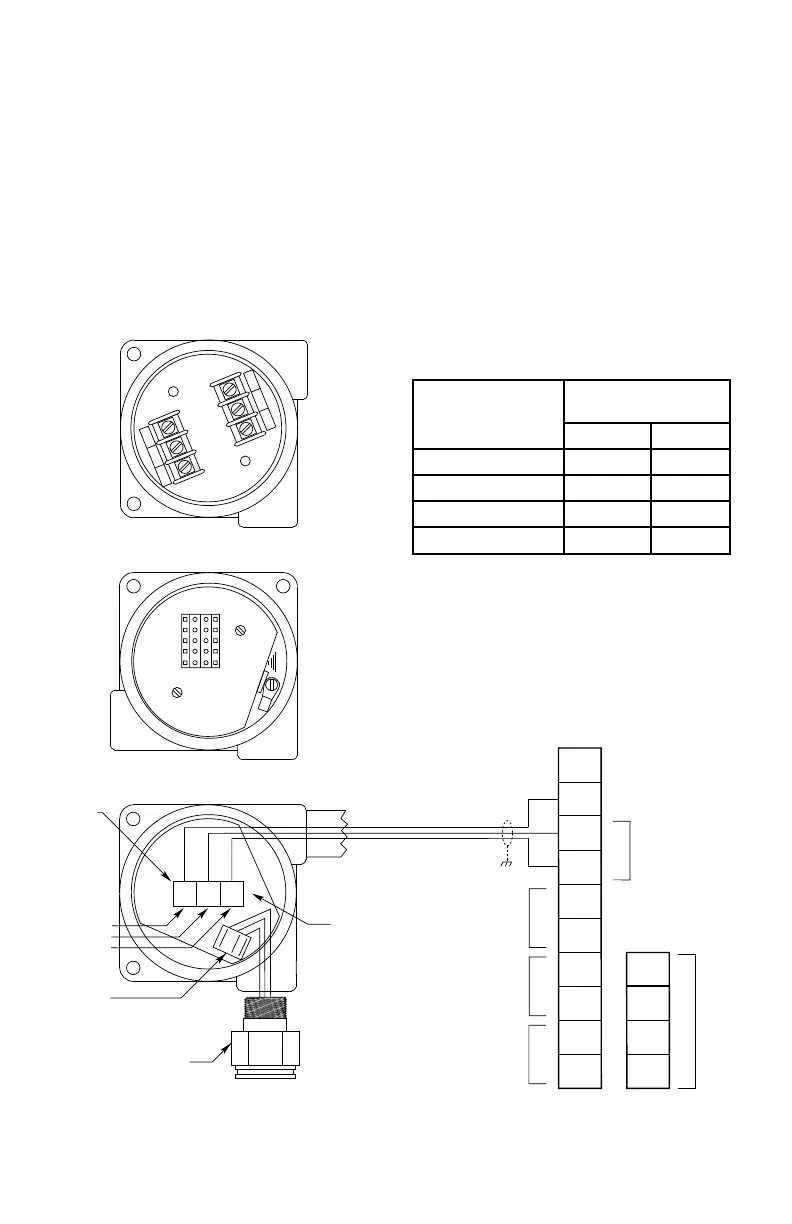

Alternate Method

If the transmitter board must be mounted

separate from the sensor (high temperature

applications, etc.), separate the sensor only,

leaving the transmitter PC board inside the

DCUEX enclosure. When using this installation

option, see Table 3-13 for maximum wiring

distances.

Mount the sensor directly to the separation kit

junction box. Use three conductor shielded

cable for the connection between the terminal

block in the separation kit junction box and P2

on the DCUEX transmitter board.

A plug with screw terminals is provided for

connecting the cable to P2 on the transmitter

board. Observe the wiring color code. Connect

the shield to the ground terminal in the DCUEX

junction box.

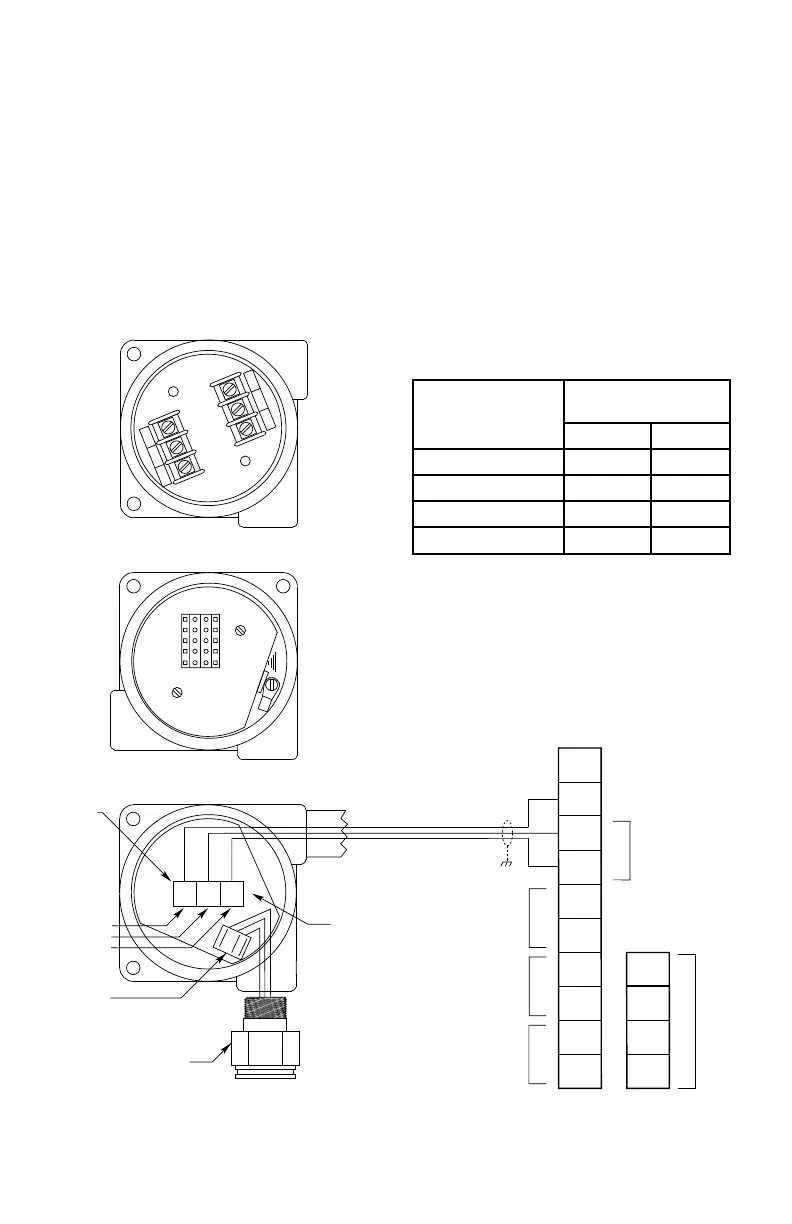

TYPICAL APPLICATIONS

Figure 3-57 is a simplified drawing of a

typical EQP system. This system includes an

EQP Controller, DCIO and various LON field

devices.

SENSOR

CATALYTIC SENSOR

ELECTROCHEMICAL SENSOR

TRANSMITTER BOARD

P1

P2

4 TO 20

–

+

C1878

POINTWATCH

GND

SPARE

CAL

4-20

RET

+24

CHASSIS

CAL

4-20

RET

+24

+

GRN

–

+

GRN

–

NOTE: ALWAYS ORIENT

JUNCTION BOX WITH

CATALYTIC SENSOR

POINTING DOWN.

1

2

3

4

5

6

7

8

9

10

DCU TERMINAL BOARD

14

13

12

11

–

–

+

+

24 VDC

COM 2

COM SHIELD

COM 1

POINTWATCH CALIBRATE

4 TO 20 MA IN

–

+

SENSOR POWER

A

B

B

A

SIG

–

+

Table 3-13—Maximum Separation Distances —

Combustible Gas Sensor to DCU (Alternate Method)

Wire Size

Maximum Separation

Distance

Feet Meters

18 AWG (1.0 mm

2

)* 40 12

16 AWG (1.5 mm

2

)* 60 18

14 AWG (2.5 mm

2

)* 100 30

12 AWG (4.0 mm

2

)* 150 45

*Approximate Metric Equivalent.

Figure 3-56—Sensor Separation Kits

Loading...

Loading...