APPENDIX B : COMPRESSOR DRIVEN AIRDRYER

B--22 20950 Issue 1 April 98

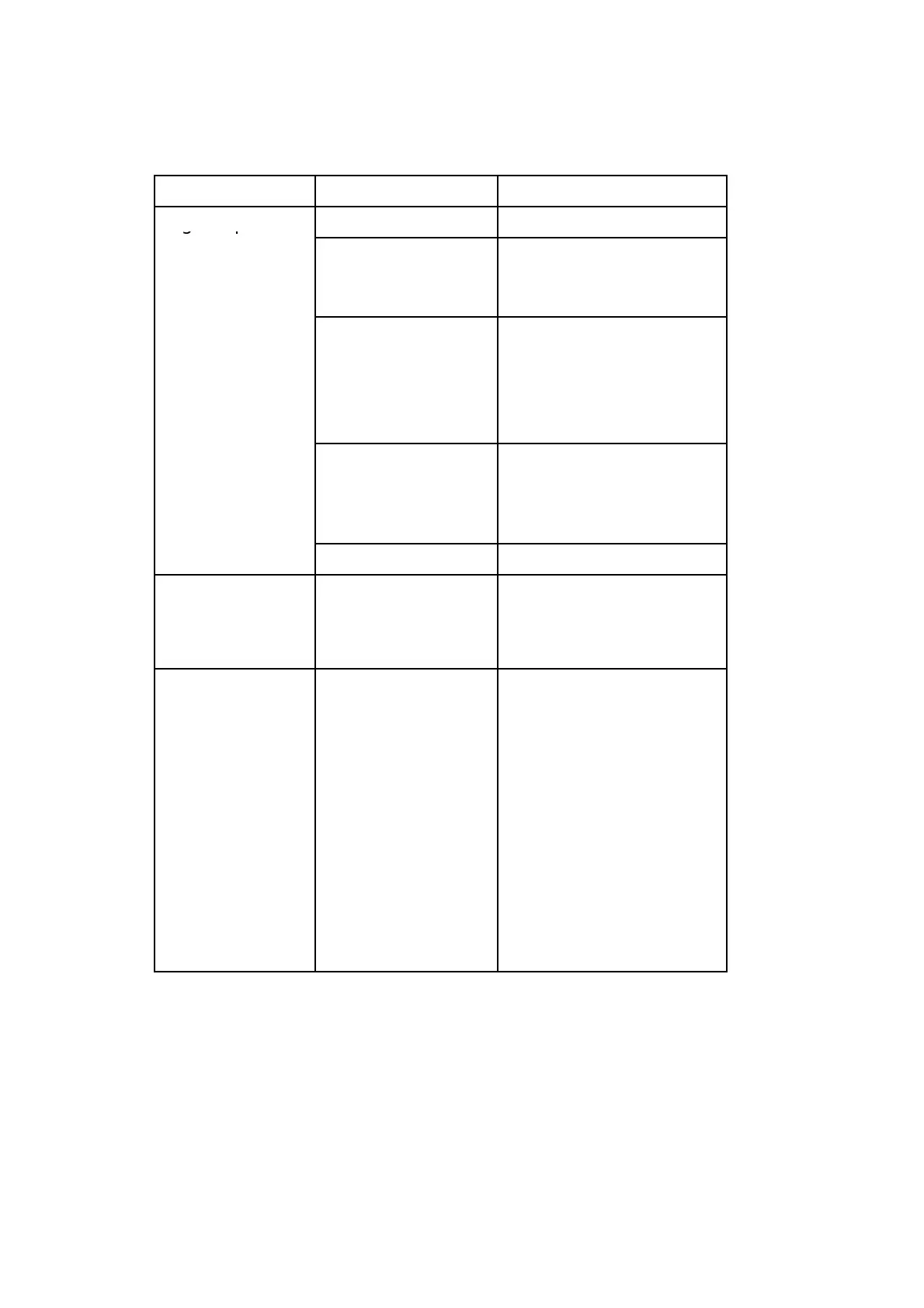

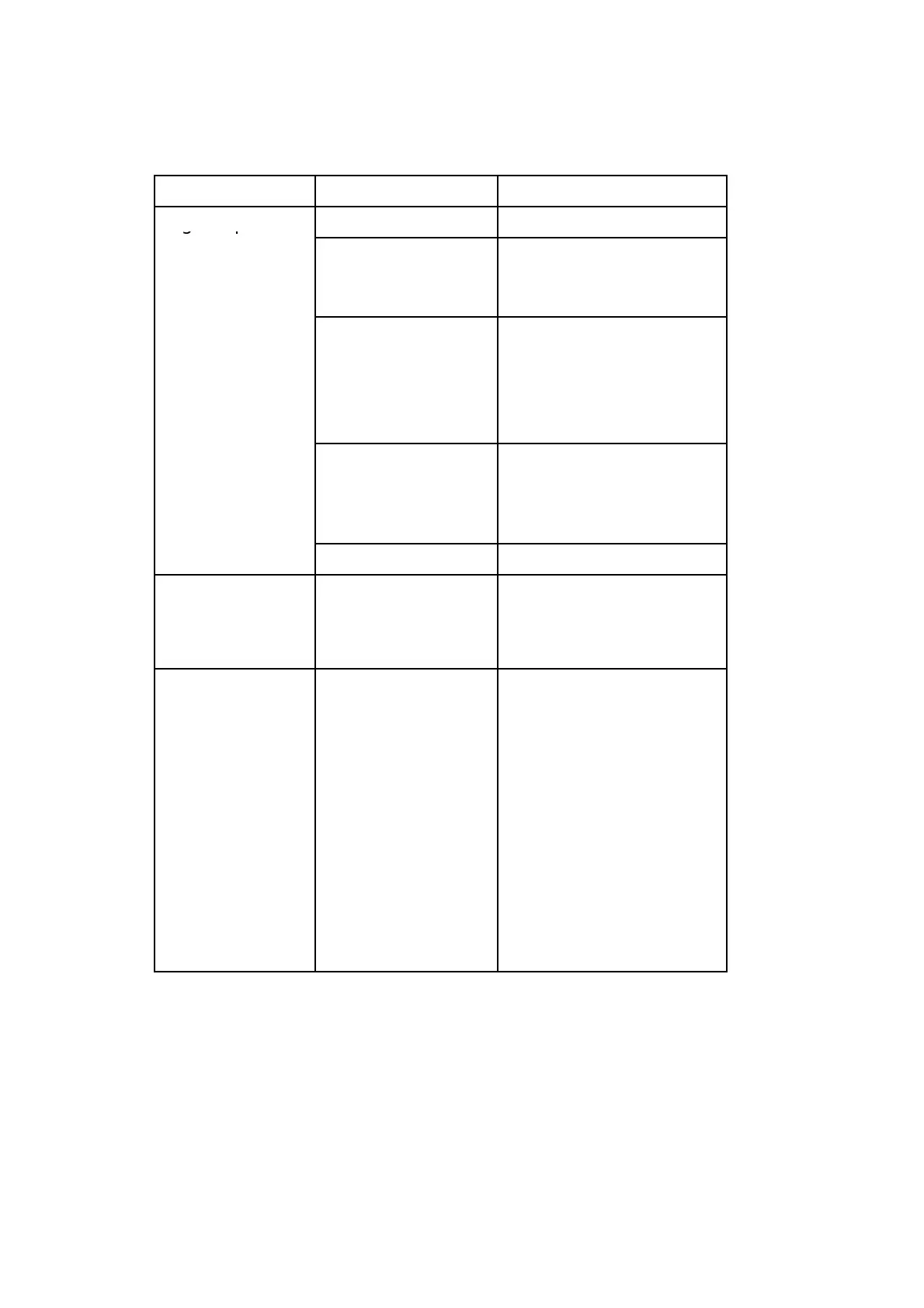

Humidity Faults

FAULT POSSIBLE CAUSE ACTION

High output

PCB fuse blown. Check fuse.

humidity or

water present in

conditioned air.

Peltier fault. Check Peltier

connections.

Check PCB.

Peltier chamber

water--logged.

Check solenoid operation.

Check PCB LK2 has

connector fitted.

Check inlet filter not

blocked.

Waste liquid not

being ejected.

Check solenoid operation.

Check PCB LK2 is

incorrect position

(normally 3--4).

Low pressure. Check for low airflow.

High output

humidity or

water present in

conditioned air.

Peltier fan not

working.

Check connections and

operation.

Output humidity

satisfactory, PCB

humidity LED

illuminated and

alarms operating.

Humidity sensor

detection incorrect.

Check tube supplying

humidity sensor correctly

placed.

Check orifice not blocked.

Set PCB SW1 to Test

mode and run dryer with

door closed for 6 minutes

to stabilise cabinet and

ensure PCB humidity

detection operates

correctly (LED goes out).

Check sensor.

Check PCB.

Loading...

Loading...