Positioning the toothed belt wheels

30 Service Instructions 867-M PREMIUM - 03.0 - 05/2017

The distance between the winder wheel (3) and the upper toothed belt

wheel (1) must be 0.8 mm.

The toothed belt (4) runs correctly without running against the retaining

ring or slipping off.

To position the upper toothed belt wheel:

1. Remove the arm cover ( p. 17).

2. Push the toothed belt (4) sufficiently far to the side so that the 2 threaded

pins (2) can be reached.

3. Loosen the threaded pins (2).

4. Turn the upper toothed belt wheel (1) so that the threaded pins (2) are

seated flush on the flat of the arm shaft (5).

5. Move the upper toothed belt wheel (1) to the side so that the distance

to the winder wheel (3) is 0.8 mm.

6. Tighten the threaded pins (2).

7. Push the toothed belt (4) back.

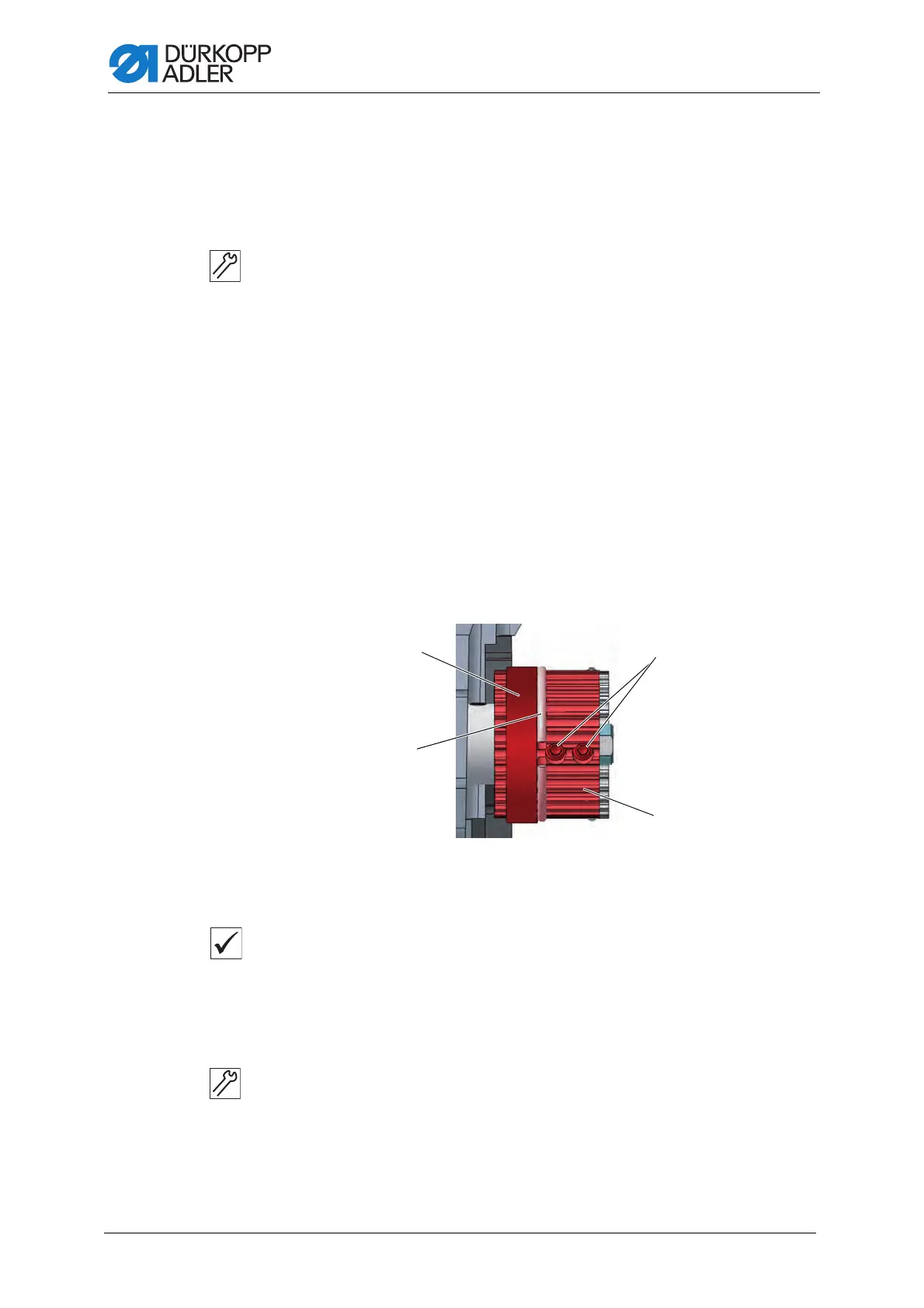

6.2 Positioning the lower toothed belt wheel

Fig. 19: Positioning the lower toothed belt wheel

Proper setting

The 2 threaded pins for the lower toothed belt wheel are seated flush on

the flat of the lower shaft.

The toothed belt (1) runs correctly without running against the retaining

ring (2) or slipping off.

To position the lower toothed belt wheel:

1. Tilt the machine head ( p. 16).

2. Loosen the threaded pins (4).

3. Turn the lower toothed belt wheel (3) such that the threaded pins (4)

are seated on the flat of the arm shaft.

(1) - Toothed belt

(2) - Retaining ring

(3) - Lower toothed belt wheel

(4) - Threaded pins

Loading...

Loading...