Maintenance - 1000h

4812164901_A.pdf2022-11-14

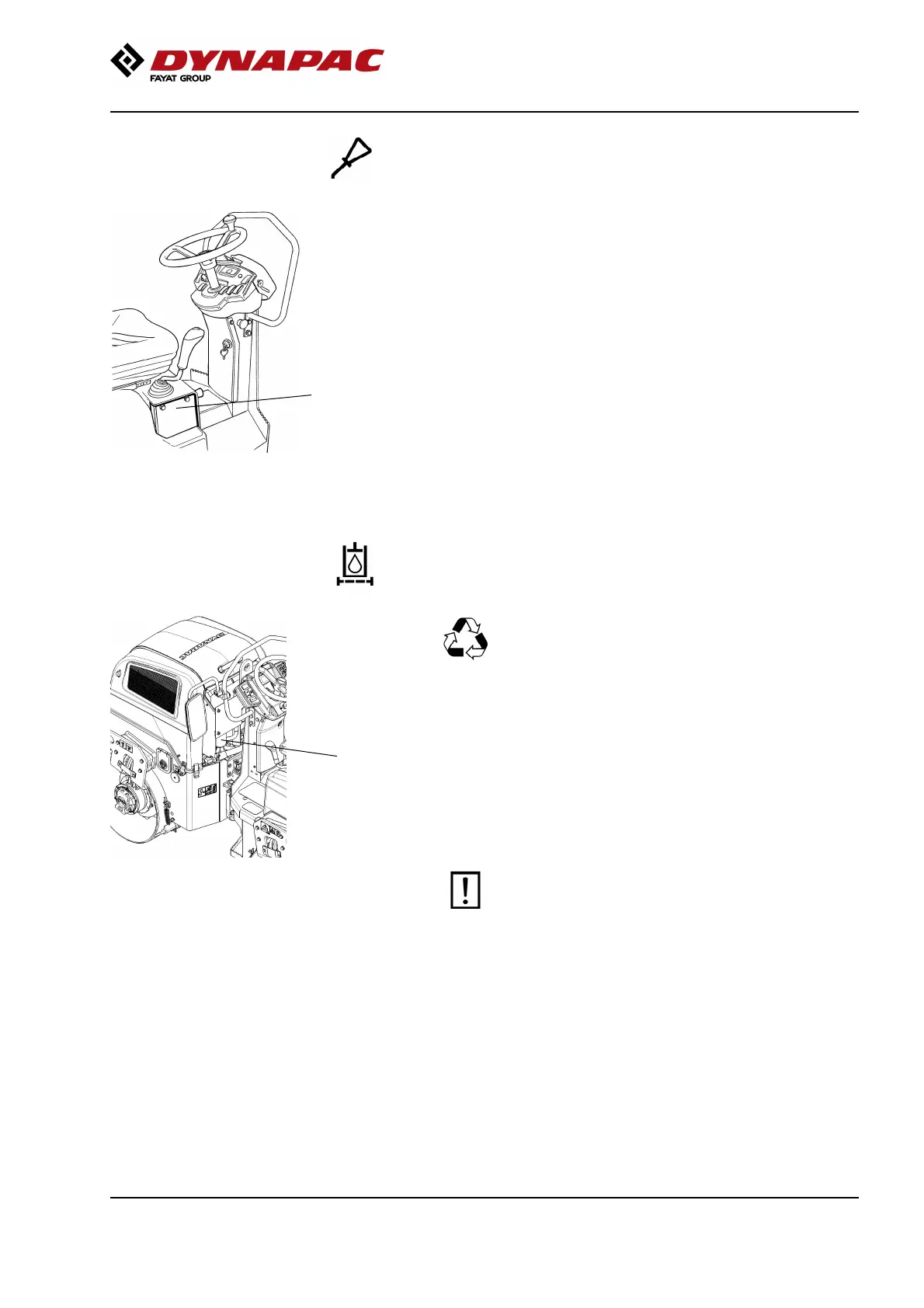

Forward/Reverse controls and joints - Check

and lubrication

Fig. Forward/Reverse lever

1. Plate

1

Remove the plate (1). Check the friction of the

forward/reverse controls. The friction screws should be

set so that the forward/reverse lever remains in the

position in which it is set whilst the machine is

operated. The control’s ‘0 position’ is determined by a

screw which engages with the groove on the shaft

between the controls.

If the control begins to be stiff after a longer period of

use, lubricate the controls by the bearings and the

control cable with a few drops of oil.

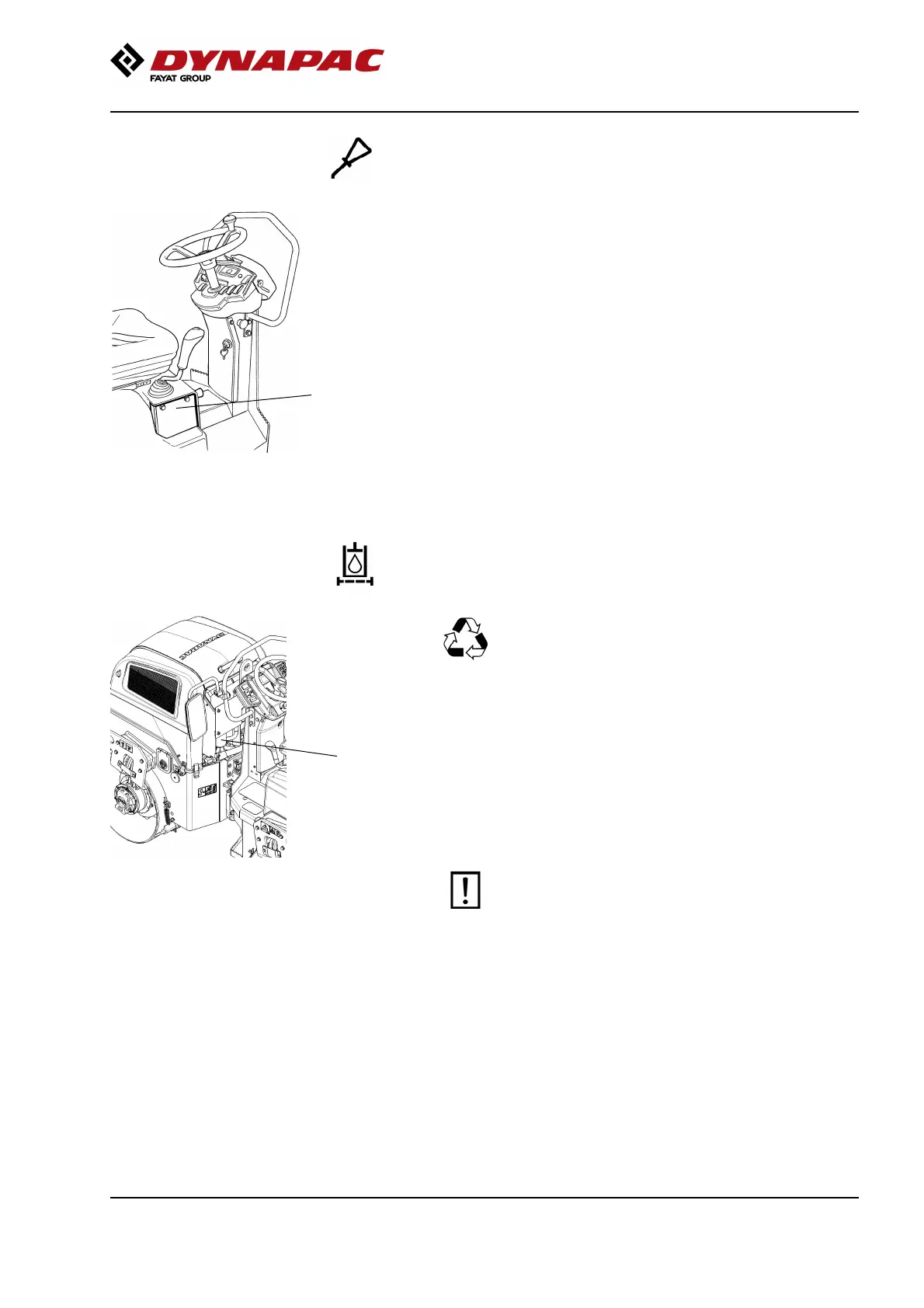

Hydraulic fluid filter - Change

Fig. Front frame, rear part

1. Hydraulic oil filter

1

Remove the filter (1) and recycle at your local

waste disposal station. This is a disposable filter

and cannot be cleaned.

Remove the filter (1) and recycle at your local

waste disposal station. This is a disposable filter

and cannot be cleaned.

Thoroughly clean the filter holder sealing surface.

Apply a thin coat of fresh hydraulic fluid to the rubber

gasket on the new filter.

Screw the filter on by hand, firstly until the filter gasket

makes contact with the filter base. Then rotate a

further ½ turn.

Do not over-tighten. The seal can be damaged.Do not over-tighten. The seal can be damaged.

Release the parking brake to activate the hydraulics

and check that the filter is not leaking.

111

Loading...

Loading...