F 8.1 9

F_8.1_01_GB.fm 9-20

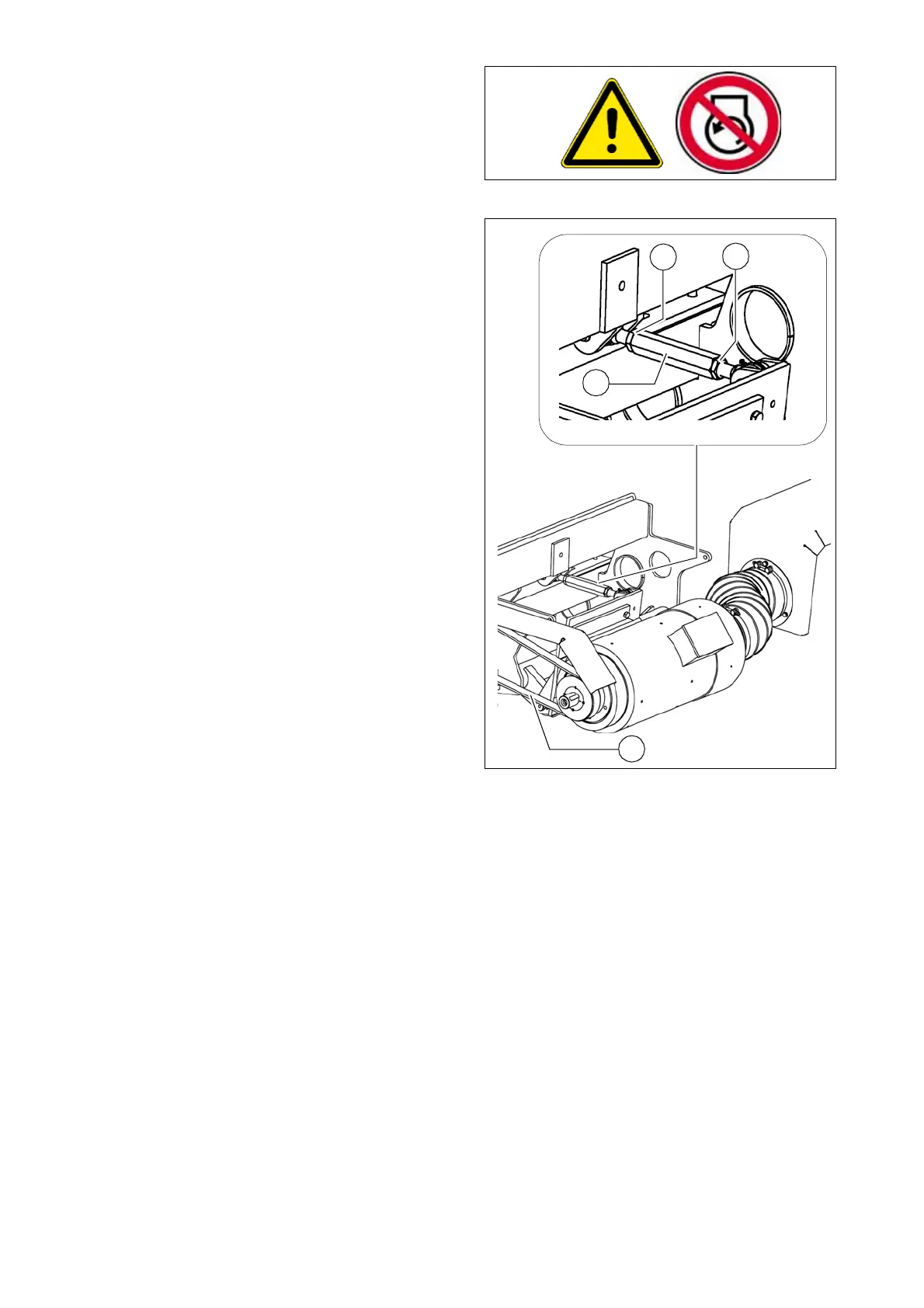

Drive belt (toothed belt)

Replacement of belt

- Unfasten both lock nuts (A) from the

clamping lock.

- Rotate and open clamping lock (B) un-

til belt (C) can be replaced.

A

Pre-tension newly fitted belt using

clamping lock (B).

- Checking / adjusting belt tension

Riemenspann.jpg

A

A

A

B

B

Loading...

Loading...