STP-iX457/iXU457 Series Turbomolecular Pump

MT-86E-001-F

Page 35

INSTALLATION

3

2) When securing the inlet port flange with claw clamps

When securing the inlet port flange with only the claw clamp, the vacuum equipment cannot

withstand the maximum rotational torque generated by the worst-case failure. To make the vacuum

equipment withstand abnormal torque, secure the base with either the 4 screws for legs or the 4

attached legs. Ensure instructions with regard to rotation stopper and bolts for securing the base are

adhered to page 33.

For the claw clamp-type, use the required number of claw clamps as specified in Table 7. Position

the claw clamps evenly on the circumference.

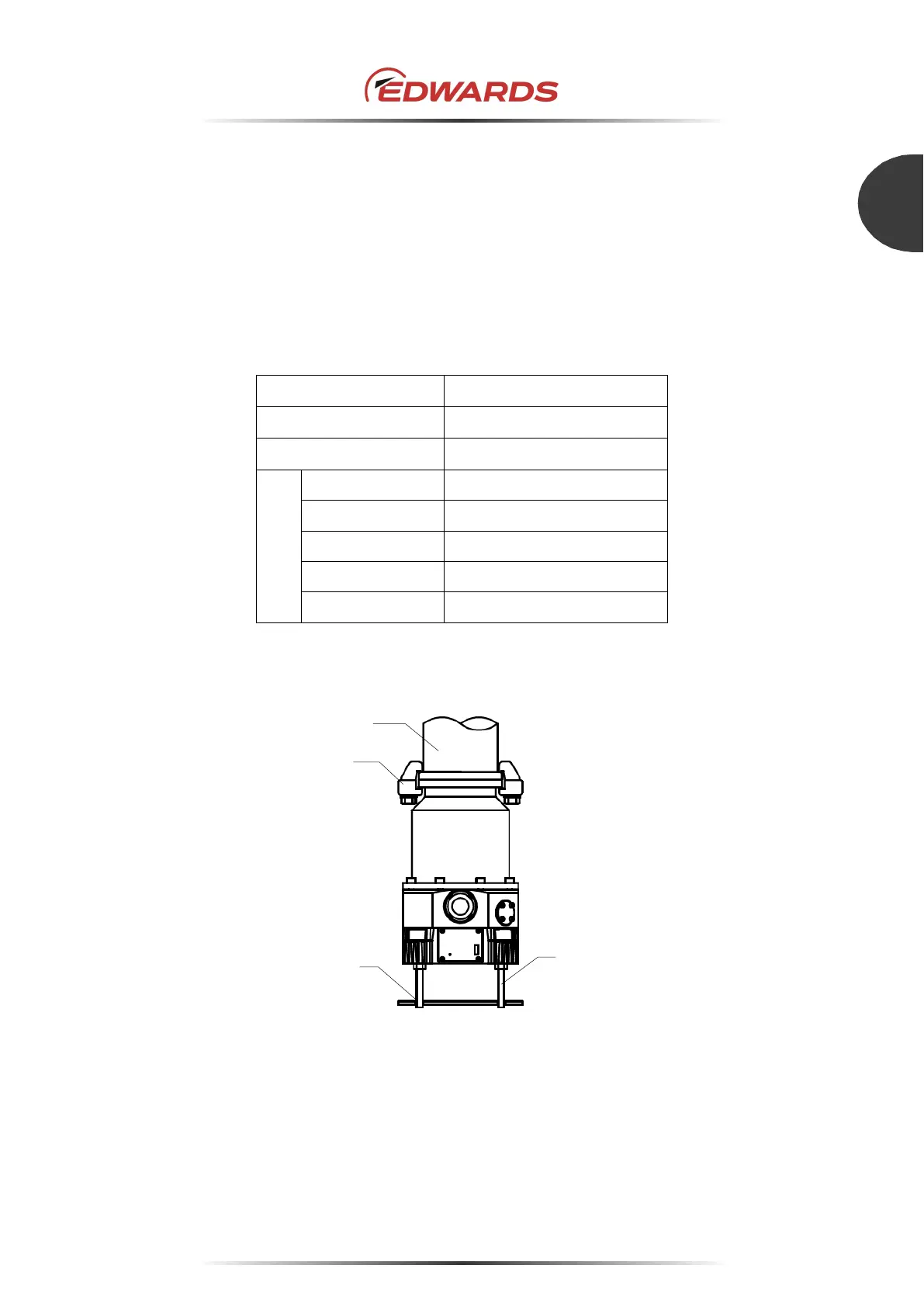

Pump model STP-iX457

Flange type

ISO160/ISO100

Destructive Torque [kNm]

4.1

Recommended

claw clamps

Shape Standard

Size M10

Q’ty 6 or more

Material

*1

Stainless steel

Strength

*1

70 or more

*1 Refer to ISO898-1 (JISB 1051), ISO3506 (JISB 1054).

Table 7 - Number of claw clamps for flange size

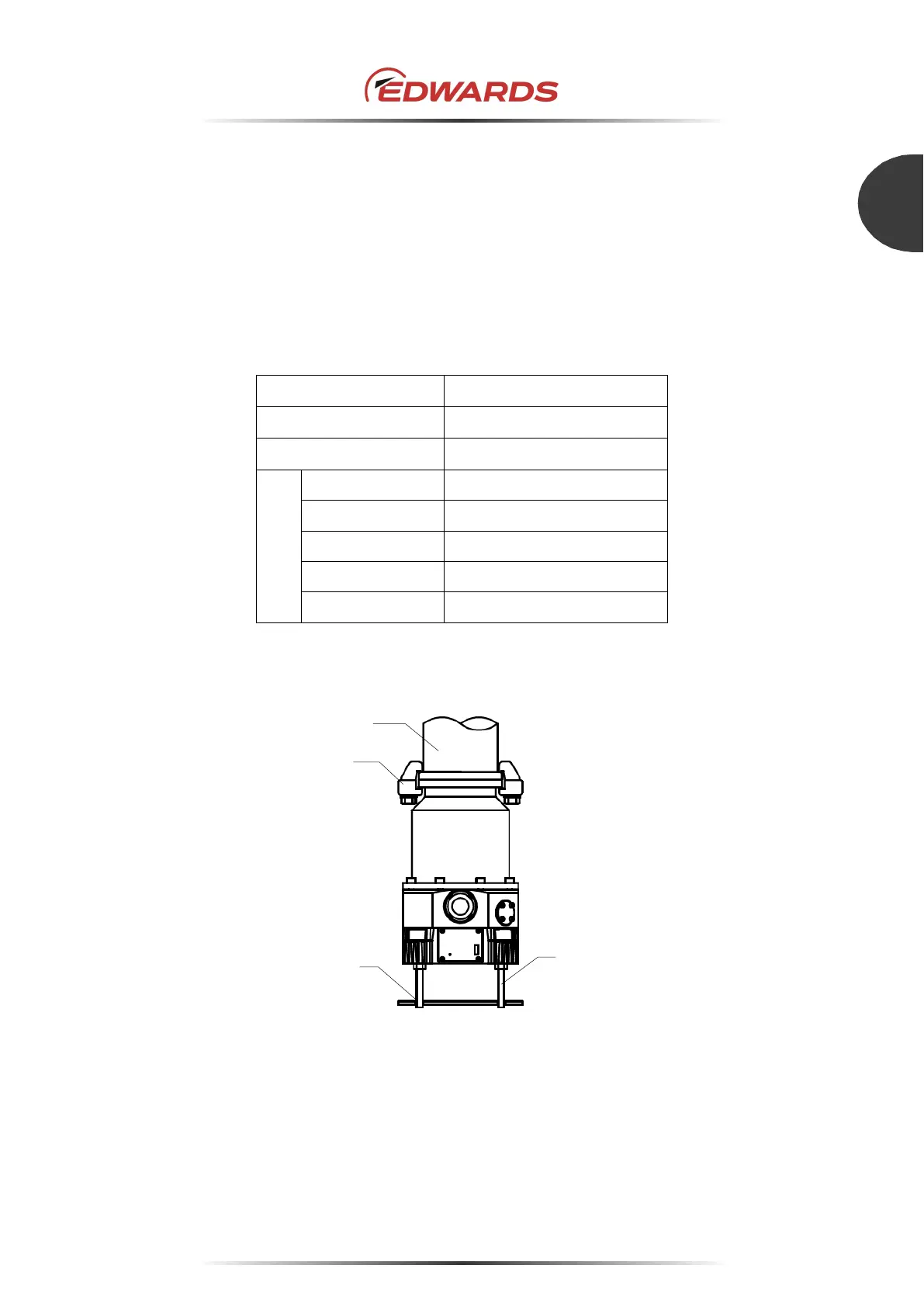

1. Vacuum equipment 3. Detent hole

2. Claw clamps 4. Rotation stopper

Figure 25 - Example of securing the STP pump

(when securing the inlet port flange with claw clamps)

2

4

3

Loading...

Loading...