3. Drive functions

3−23

Festo P.BE−CPX−CMA X−CONTROL−EN en 0908NH

Regarding Fig.3/6:

1 to 3: Setpoint value and actual value curves. The setpoint

value here refers to the reference setpoint value which is gen

erated by the trajectory planning.

4 to 6: Enlarged illustration of the control fault and the two

tolerances. The following error tolerance (11 mm) is much

greater than the

positioning tolerance (0.1 to 10 mm or 0.004

to 0.394 in).

7: The MC signal determines which tolerance is used.

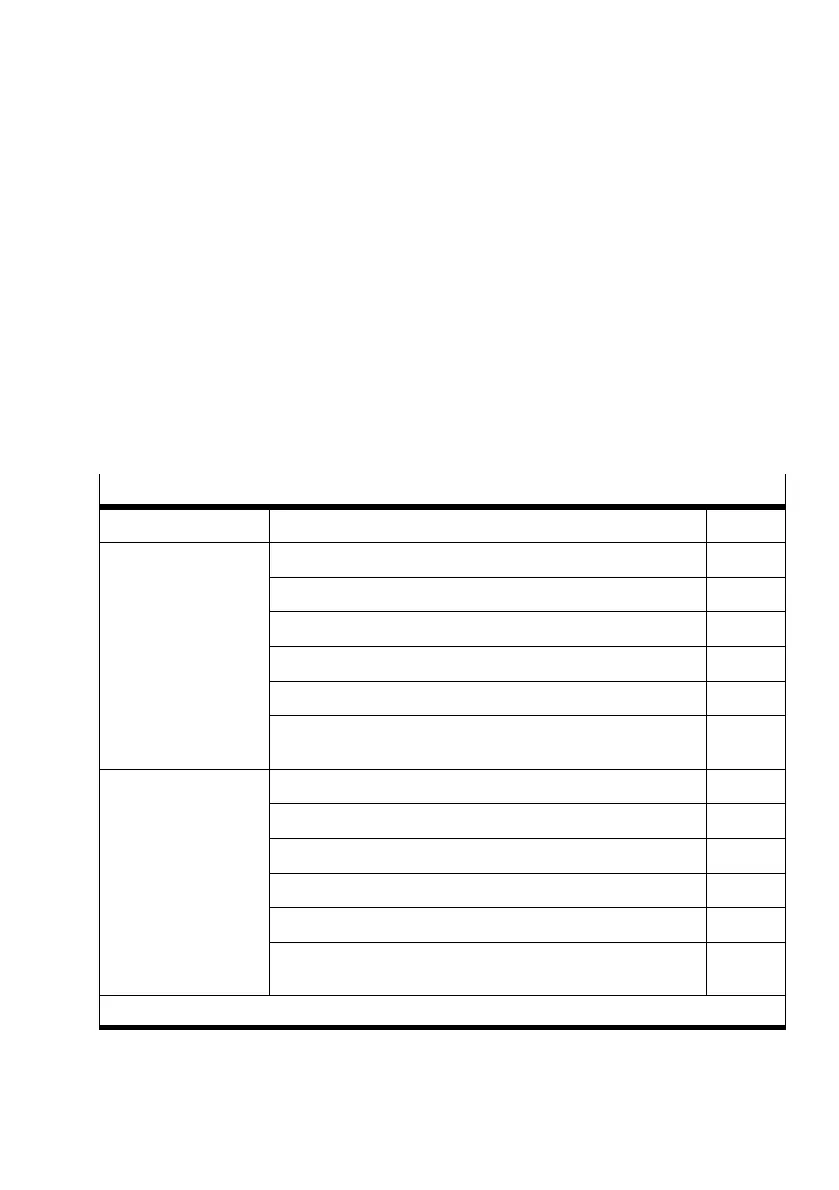

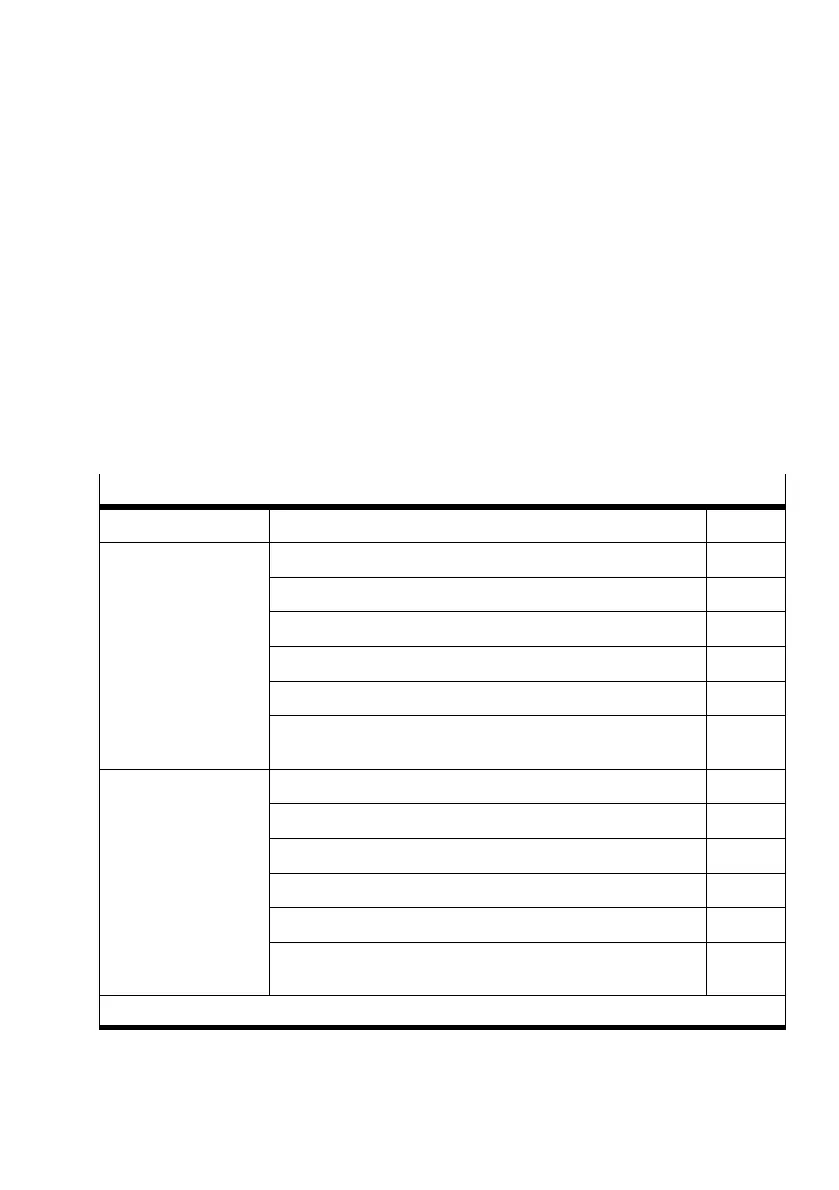

Overview of parameters involved (see section 5.4.6)

Parameters involved Description PNU

Position control Target setpoint value: Target position 300:02

Output of the reference setpoint value generator − position

1)

Actual value: Actual position 300:01

Current deviation: Position deviation 300:03

Following error tolerance (fixed: 11 mm or 0.43 in)

Positioning tolerance 411:xx or

545

Force control Target setpoint value: Target force 301:02

Output of the reference setpoint value generator − force

1)

Actual value: Actual force 301:01

Force deviation 301:03

Following error tolerance (fixed: 5 N or 1.12 lbf)

Force tolerance 411:xx

or 552

1)

No parameter defined, but available in trace

Tab.3/8: Involved following error or tolerance monitoring parameters

Loading...

Loading...