QUANTUM™ LX EVAPORATOR CONTROL PANEL

OPERATION

090.610-O (MAR 2016)

Page 6

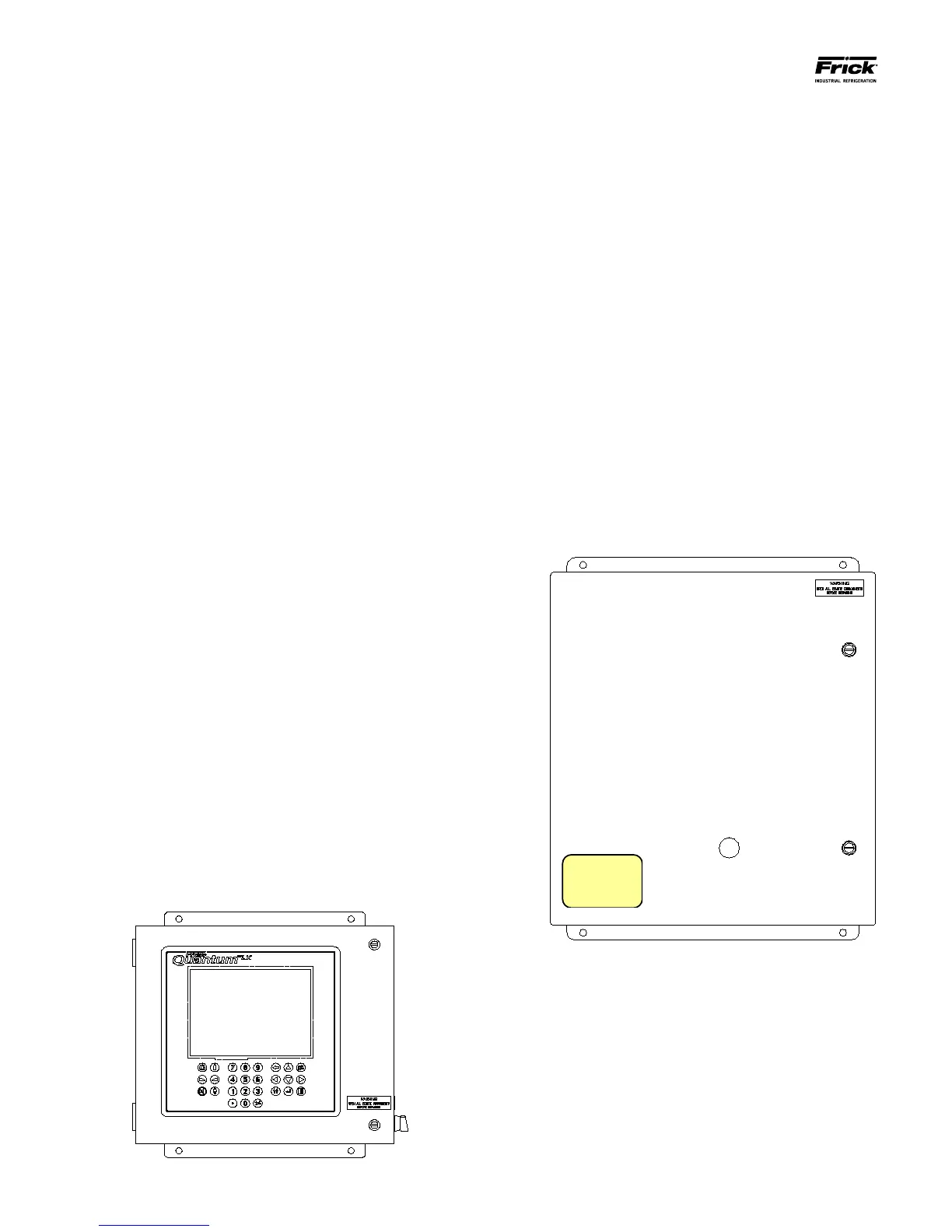

The Operator Interface Panel (we will call it the In-

terface Panel throughout the rest of this guide) is the

central point of the system, whereby all Remote Zone

Interface Panels are attached. It can easily be identi-

ed by the presence of a display screen and a keypad.

The Interface Panel monitors and controls all of the

Remote panels that are attached to it, through RS-

485 serial communications (to be explained later).

The Interface Panel runs the actual program that

provides the control for the entire system. Through

communications, it monitors the status of each

attached Remote Zone Interface Panel, and provides

the necessary control instructions for each Remote

Zone Interface Panel to perform. Additionally, all

setpoints are stored in the Interface Panel.

Status of the entire system may be monitored form

here, and appropriate changes made to system

operation.

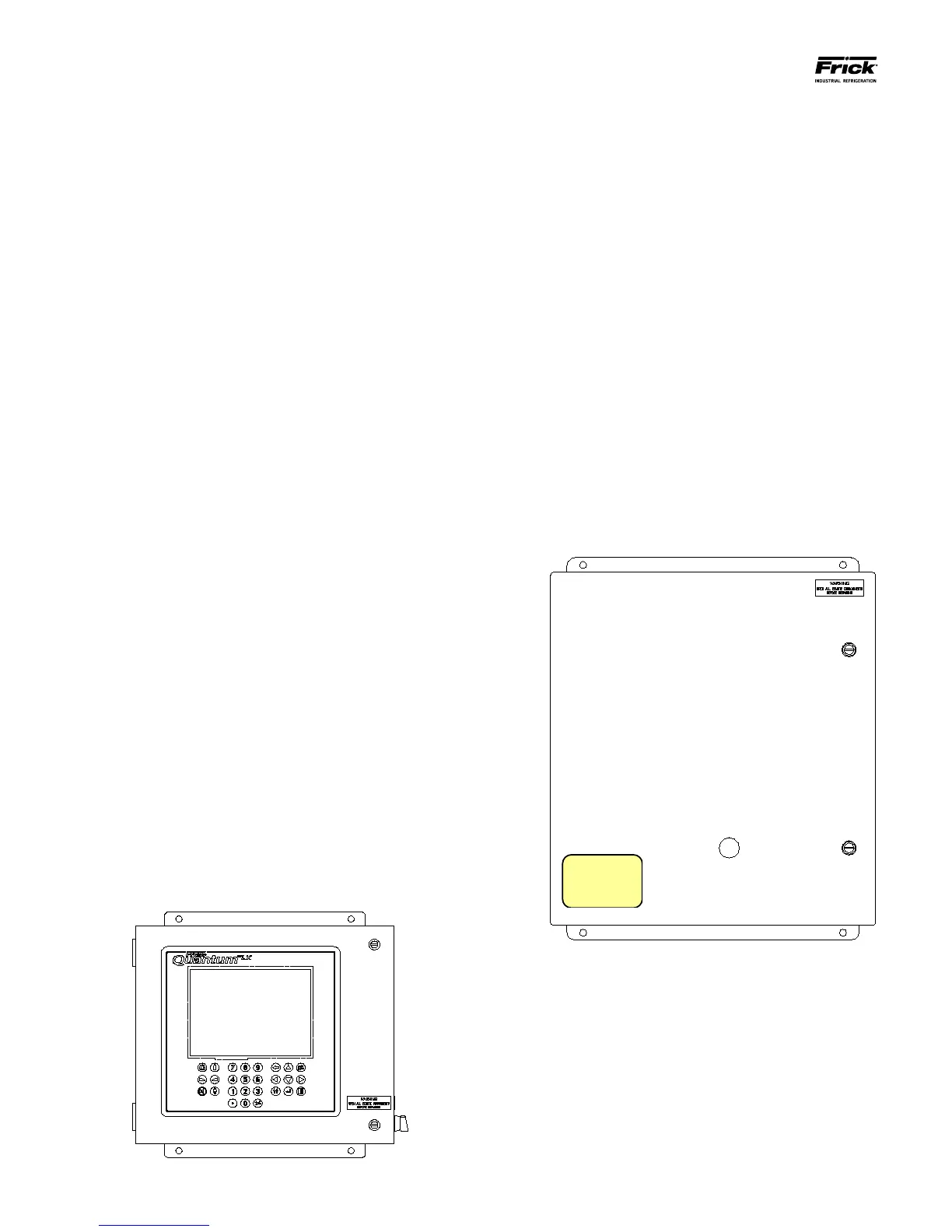

THE REMOTE I/O PANEL

Each complete Evaporator system will have from one

to ten Remote I/O Panels, and each panel is capable

of controlling up to 3 Evaporator zones:

Quantum LX Evaporator

Remote Panel Number: ___________

Notice that there is a yellow sticker on the front

of the door for each Remote I/O Panel. This sticker

will identify the Remote Panel number and the

Zones it will control. This will all be explained in

greater detail later, but it is an important fact to

note.

The Remote Panels do not have a display or keypad. Each

Remote Panel can control three independent Zones. Each

Quantum™ LX Evaporator system can manage up to 10

Remote I/O Panels, providing the ability to control as

many as 30 Evaporator zones.

SETUP DESCRIPTION

The following Setup Guide is meant to assist the installation

technician in making all necessary electrical power, control and

communications connections to a Quantum™ LX Evaporator

system. They will be provided also with the basic information

necessary to login and congure the system. It will then aid in

troubleshooting the system should problems arise. This Guide

will help to ensure:

WIRING

• Location of incoming AC source power to all

panels (Interface and Remote)

• Basic installation guidelines are followed.

• Location, polarity and grounding of

communications wiring.

• Location of all control (I/O) wiring.

• Proper powering up of all panels.

CONFIGURATION

• Logging into the system.

• Verifying communications.

• Conguring the Zones.

• Calibrating sensors.

• Setting up operating Setpoints.

OPERATION

• Setting the operating Mode.

• Verifying the data being returned to the Interface

panel from all remote panels (Zones).

• Checking and clearing of alarms.

• Zone overview

• Ammonia Conguration

IDENTIFYING AN EVAPORATOR SYSTEM

A minimum Evaporator system will include one Operator

Interface Panel and one Remote I/O Panel.

THE OPERATOR INTERFACE PANEL

Each complete Evaporator system will have a single

Operator Interface Panel, as shown below:

Loading...

Loading...