5.4 Details of Function Codes

5-240

Return home (Encoder pulse number) (d15)

d15 sets the encoder pulse number of the speed feedback input.

- Data setting range: 0014 to EA60 (in hex.)

(Above range becomes 20 to 60000 (P/R) in decimal.)

Set "0400 (1024 P/R)" when an exclusive motor for Fuji vector control is used.

Return home (Pulse compensation factor 1) (d16), (Pulse compensation factor 2) (d17)

d16 and d17 set the factors to convert the speed feedback input pulse rate into the motor shaft speed.

- Data setting rage: 1 to 9999

Set the data according to the pulley and gear ratios as follows.

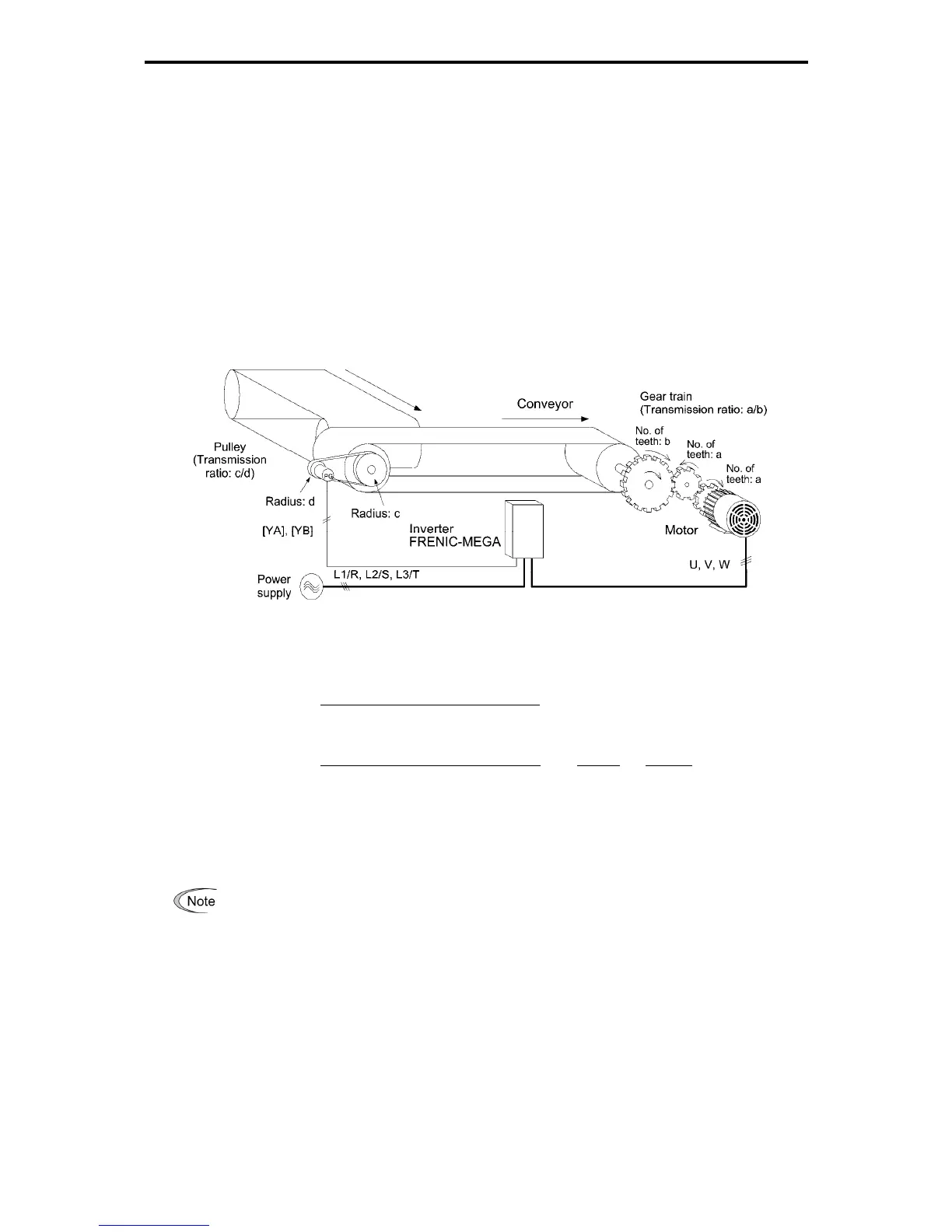

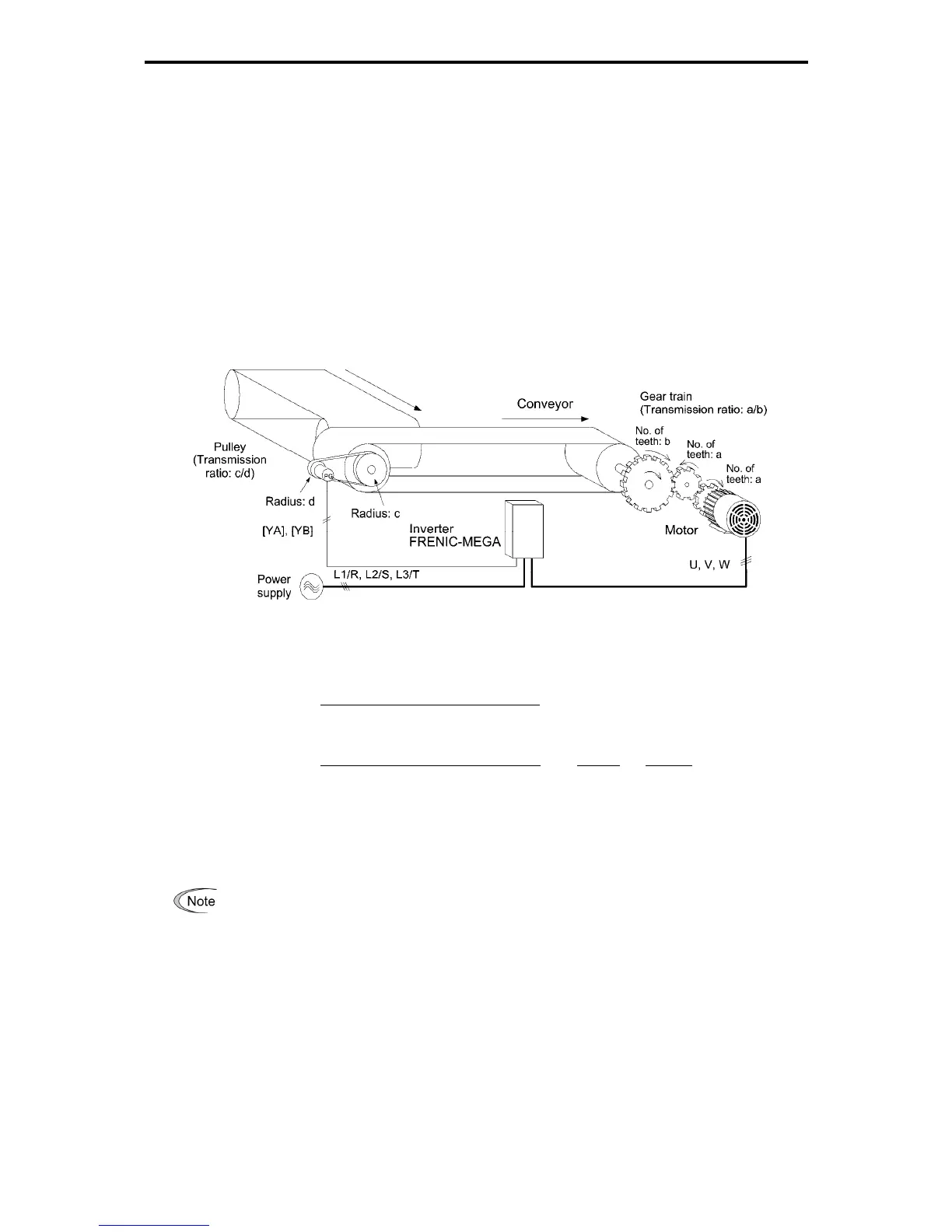

Fig. 5.4-123 Example of a Closed Loop Speed Control System (Conveyor)

Conversion expressions of the motor shaft speed of the speed feedback input.

Pulse compensation factor 2 (d17)

Motor shaft speed =

Pulse compensation factor 1 (d16)

x Encoder shaft speed

Pulse compensation factor 2 (d17) b d

Pulse compensation factor 1 (d16)

=

a

X

c

Pulse compensation factor 1 (d16) = a X c

Pulse compensation factor 2 (d17) = b X d

When executing the vector control with speed sensor, mount the speed detector pulse encoder

on the motor shaft directly, or on a shaft with the rigidity equivalent to the motor shaft. When a

backlash or deflection exists, proper control may become not possible.

When the motor exclusively used for Fuji vector control is used, the pulse encoder is directly

mounted on the motor shaft. Therefore, set "1" to both pulse compensation factor 1 (d16) and

pulse compensation factor 2 (d17).

Loading...

Loading...