10.4 Selecting a Motor Drive Control

10-23

Chapter 10 SELECTING OPTIMAL MOTOR AND INVERTER CAPACITIES

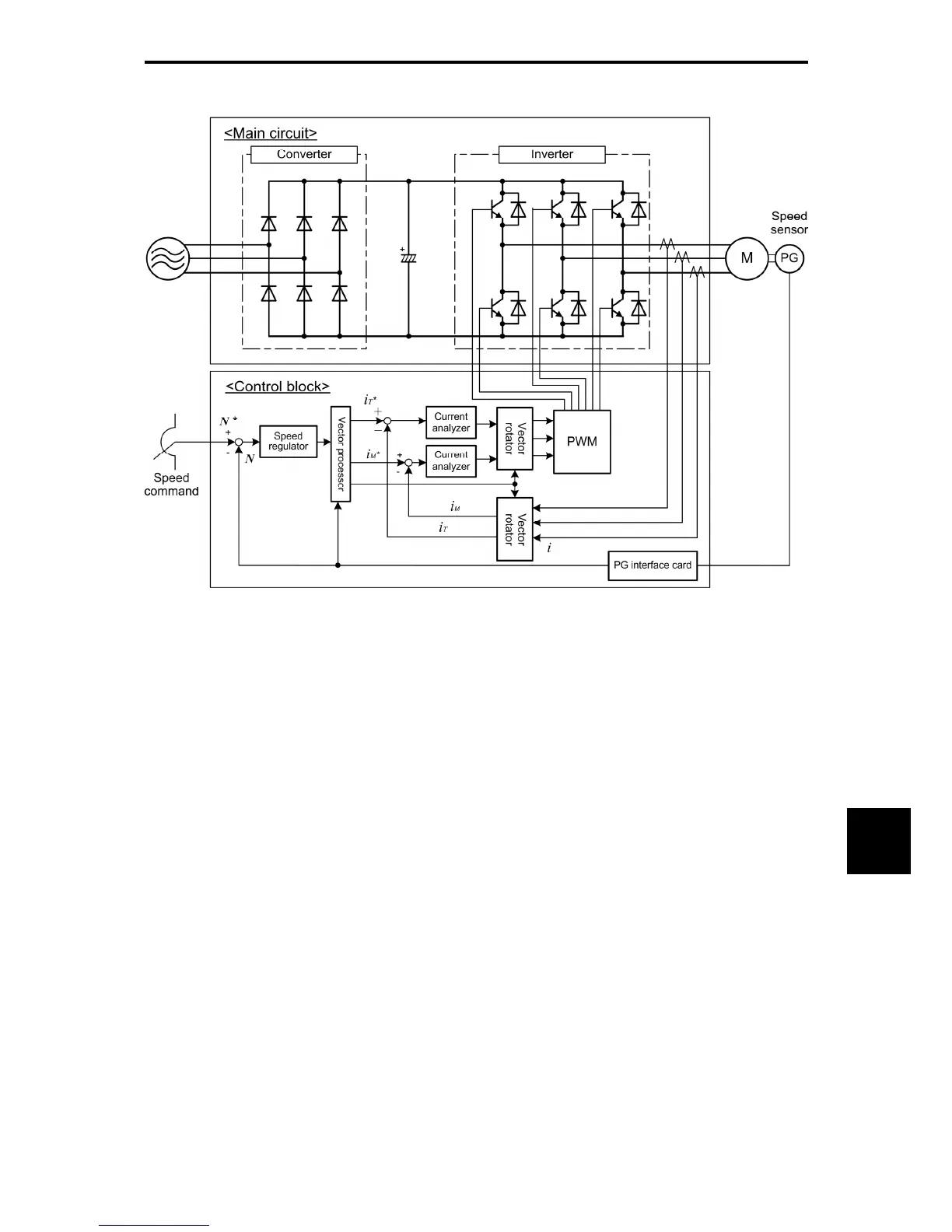

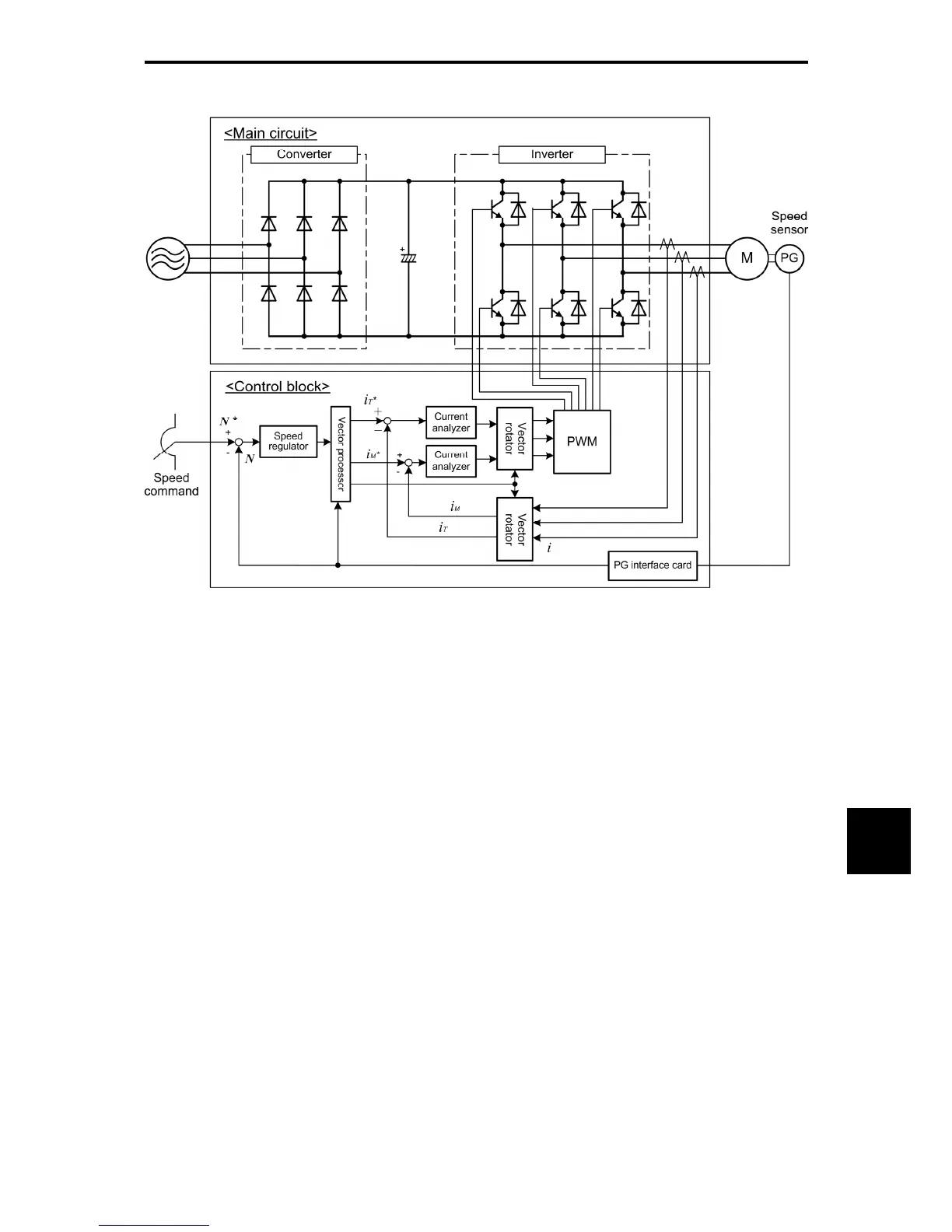

Vector control with speed sensor

Figure 10.4-5 Schematic Block Diagram of Vector Control with Speed Sensor

As shown in the above configuration, the inverter is equipped with an optional PG (Pulse Generator)

interface card and receives the feedback signals from the PG to detect the motor rotational position and

speed. This enables rapid-response control of the motor speed with high accuracy. (It is recommended to

use Fuji motors exclusively designed for vector control.)

By dividing the current flowing across the motor into the exciting current and torque current to control them

separately, the inverter can control an induction motor with as high controllability as a DC motor. This

control is suitable for:

• Applications that need to minimize the speed fluctuation over quick load variations

• Applications that need highly precise positioning

• Applications that need the servo-lock function to generate a holding torque negating external

disturbances even while the motor is stopping

• Applications that need large torque output in low speed operation

• Applications that need to protect the equipment from an unexpectedly outputted large torque, because

the torque limiting/controlling function is available

Loading...

Loading...