10.4 Selecting a Motor Drive Control

10-22

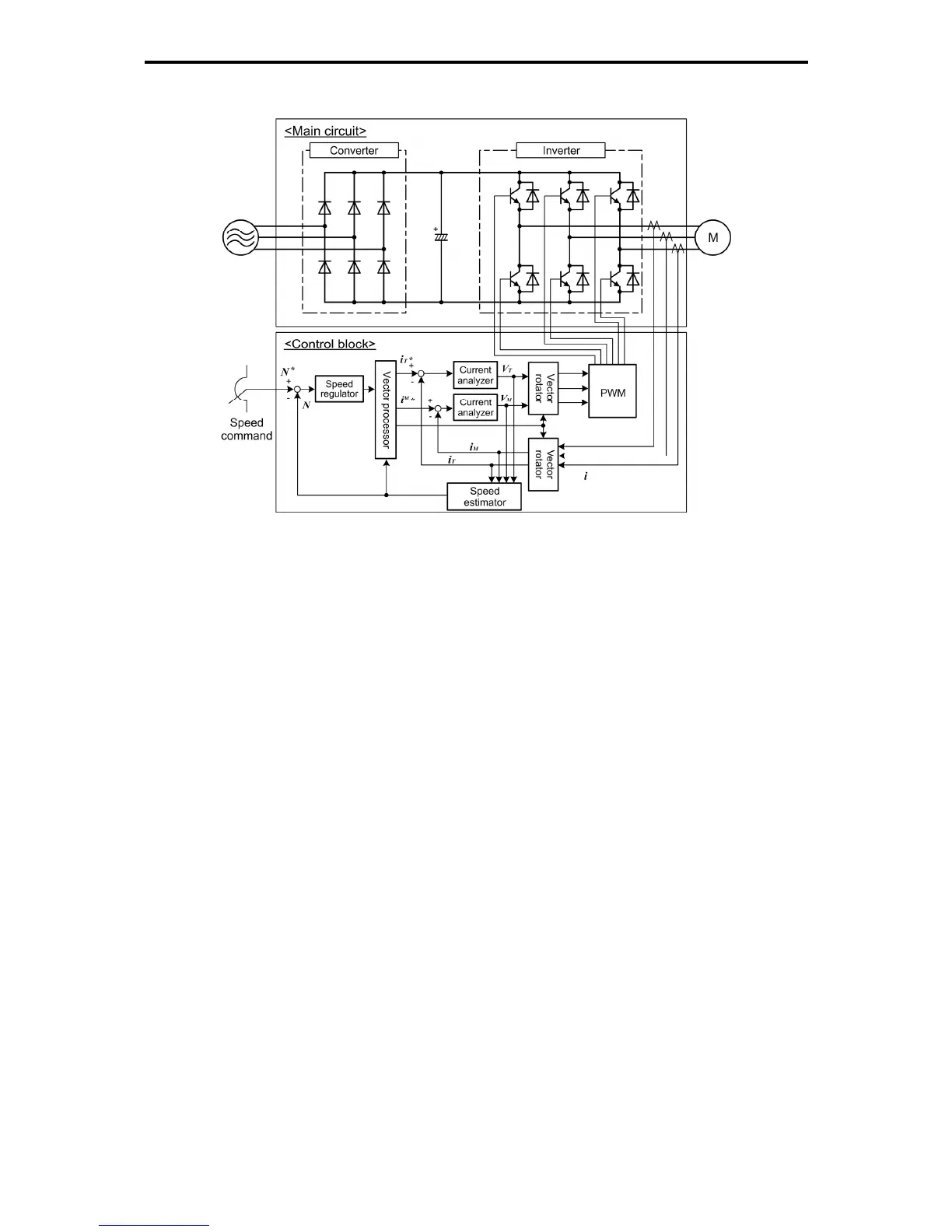

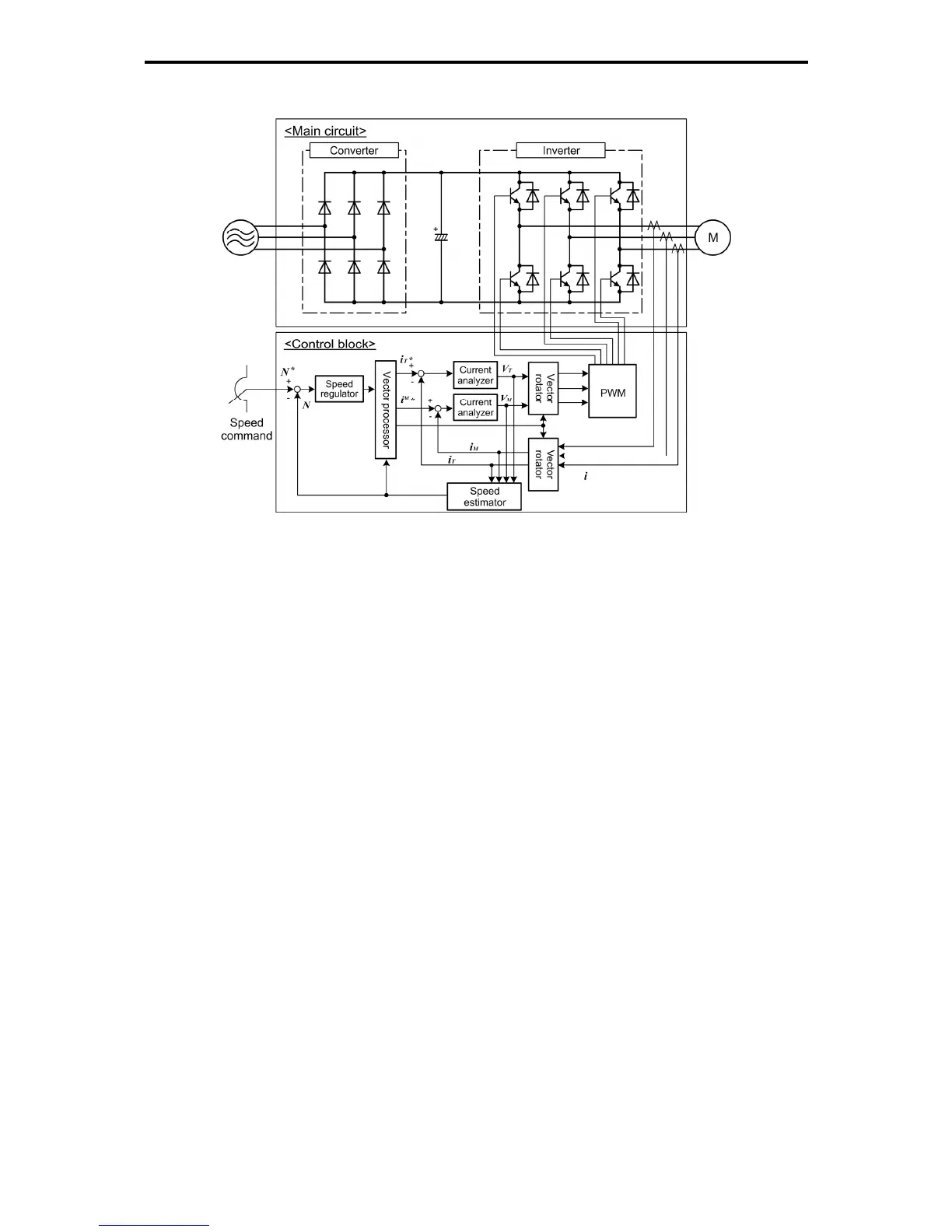

Vector control without speed sensor

Figure 10.4-4 Schematic Block Diagram of Vector Control without Speed Sensor

This control estimates the motor speed based on the inverter's output voltage and current to use the

estimated speed for speed control. It also decomposes the motor drive current into the exciting and torque

current components, and controls each of those components in vector. No PG (pulse generator) interface

card is required. It is possible to obtain the desired response by adjusting the control constants (PI

constants) using the speed regulator (PI controller).

The vector control without speed sensor in the FRENIC-MEGA series has adopted the magnetic flux

observer system, improving the control performance in the low speed domain.

Since this control controls the motor current, it is necessary to secure some voltage margin between the

voltage that the inverter can output and the induced voltage of the motor, by keeping the former lower than

the latter. Usually a general-purpose motor is so designed that the voltage matches the commercial power.

Under the control, therefore, it is necessary to suppress the motor terminal voltage to the lower level in

order to secure the voltage margin required. However, driving the motor with the motor terminal voltage

suppressed to the lower level cannot generate the rated torque even if the rated current originally specified

for the motor is applied. To ensure the rated torque, it is necessary to increase the rated current. (This also

applies to vector control with speed sensor.)

The control is not available in MD-mode inverters, so do not set F42 data to "5" for those inverters.

Loading...

Loading...