10.4 Selecting a Motor Drive Control

10-21

Chapter 10 SELECTING OPTIMAL MOTOR AND INVERTER CAPACITIES

The FRENIC-MEGA features the dynamic torque vector controller with the flux estimator, which is always

correcting the magnetic flux phase while monitoring the inverter output current as the feedback. This

feature allows the inverter to always apply the drive power with an optimal voltage and current and

consequently respond to quick load variation or speed change. The feature also estimates the generated

torque of the motor from the estimated flux data and output current to the motor to improve the motor

efficiency for matching the current operation situation. This control mode is effective for applications that

need large torque in low speed range or that have quick load fluctuations. Selecting the dynamic torque

vector control automatically enables the auto-torque boost and slip compensation.

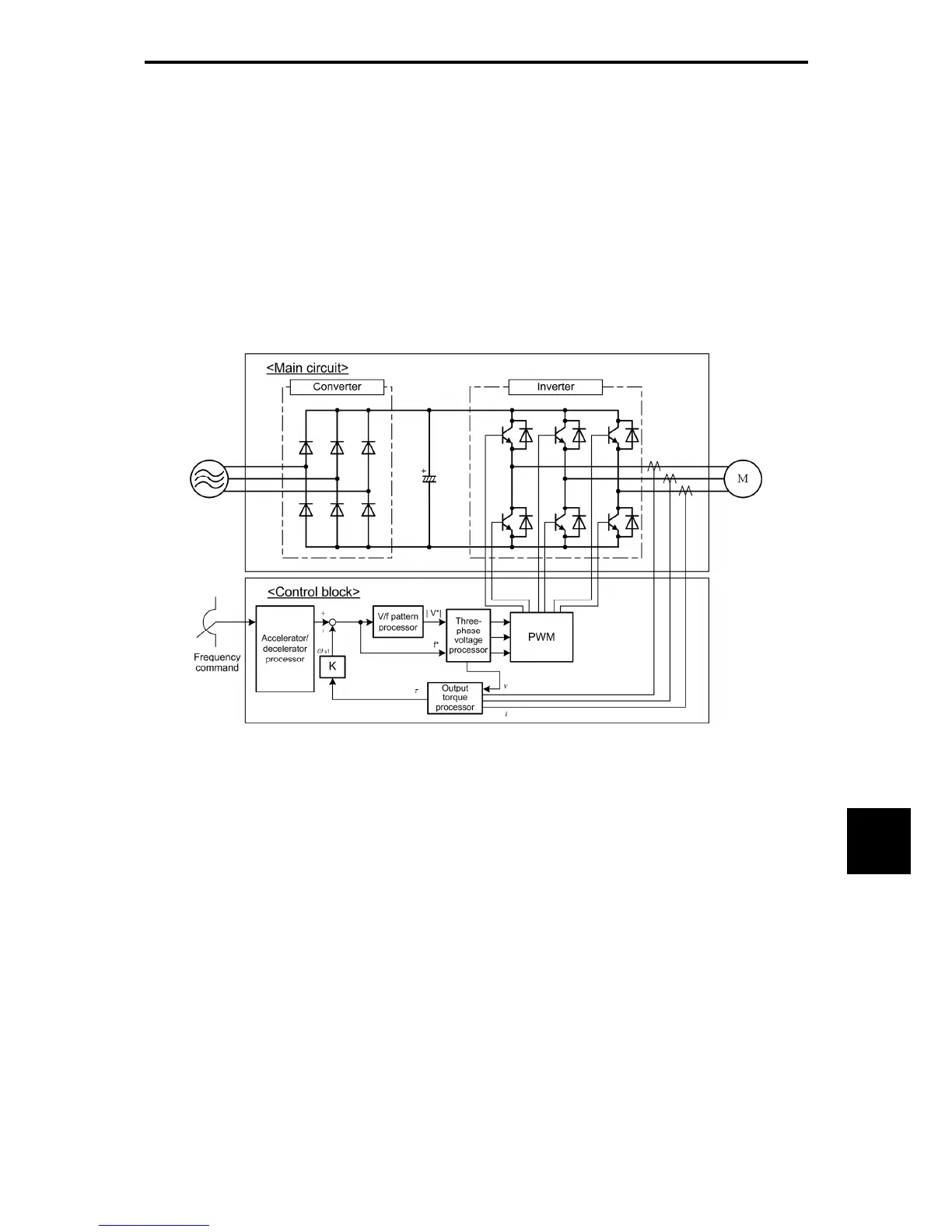

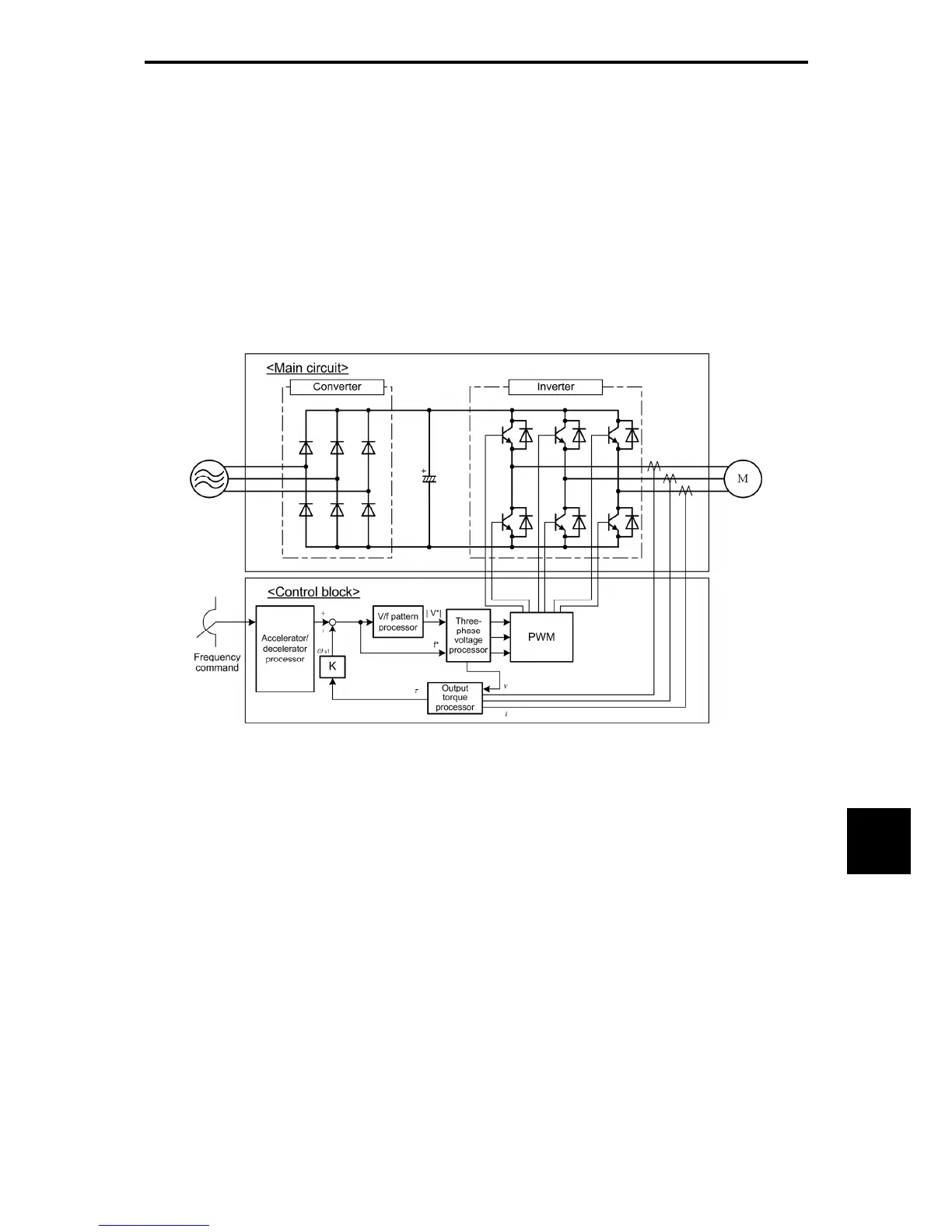

V/f control with slip compensation active

Figure 10.4-3 Schematic Block Diagram of V/f Control with Slip Compensation Active

Applying any load to an induction motor causes a rotational slip due to the motor characteristics,

decreasing the motor rotation. The inverter's slip compensation function first presumes the slip value of the

motor based on the motor torque generated and raises the output frequency to compensate for the

decrease in motor rotation. This prevents the motor from decreasing the rotation due to the slip. That is,

this function is effective for improving the motor speed control accuracy.

Loading...

Loading...