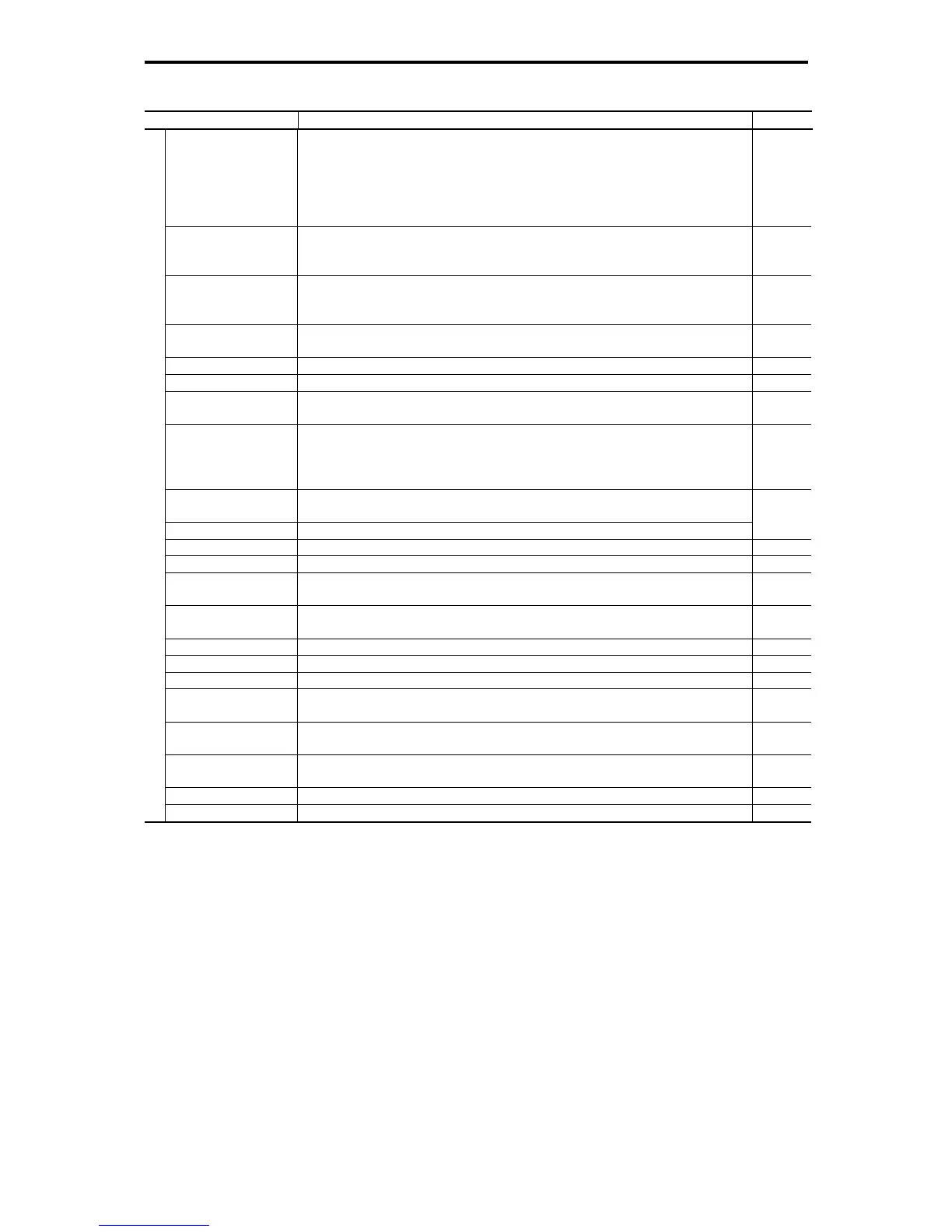

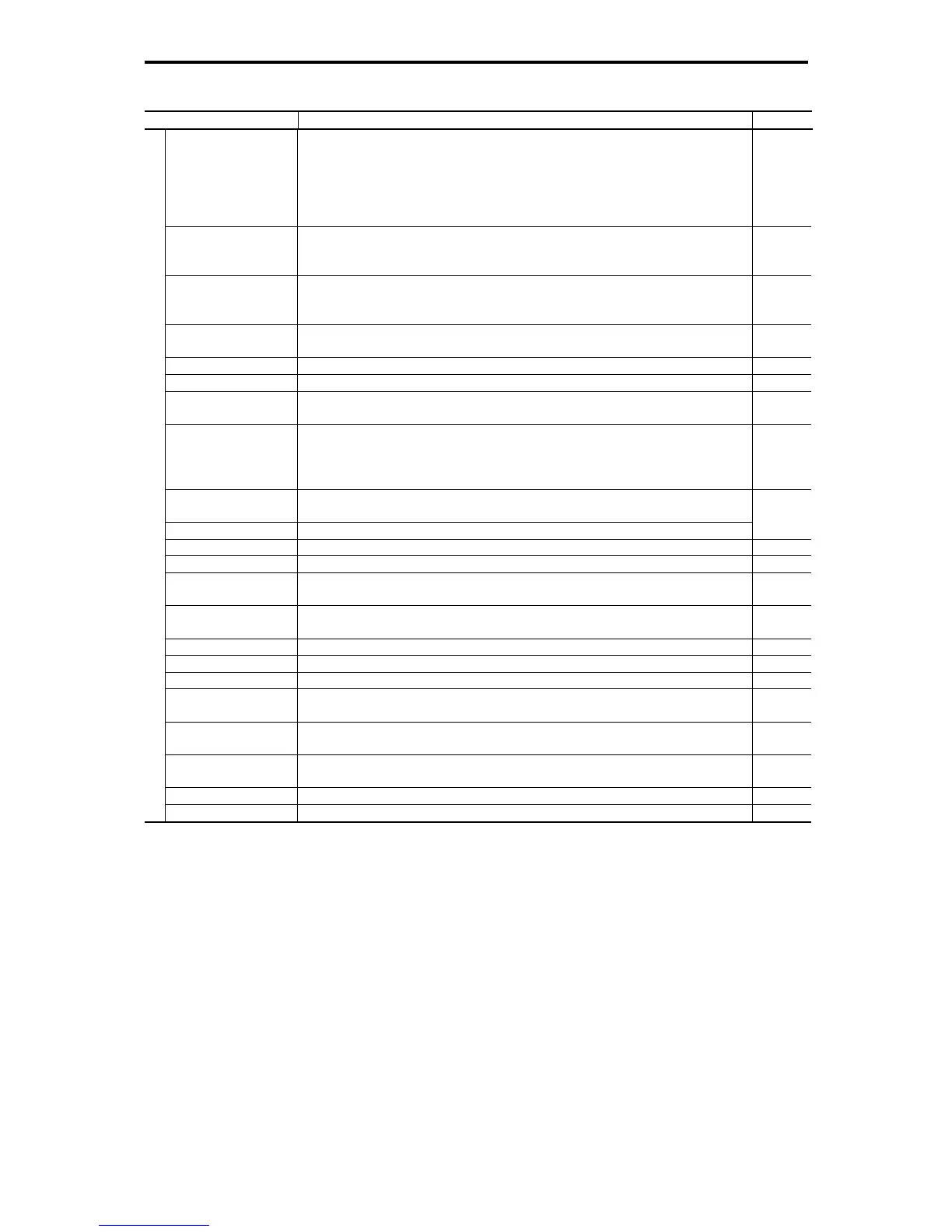

12.4 Common Specifications

12-14

Table 12.4-4

Item Explanation Remarks

Anti-regenerative control

(Automatic deceleration)

• If the DC link bus voltage or calculated torque exceeds the automatic deceleration level during

deceleration, the inverter automatically prolongs the deceleration time to avoid overvoltage trip.

(It is possible to select forcible deceleration actuated when the deceleration time becomes three

times longer.)

• If the calculated torque exceeds automatic deceleration level during constant speed operation,

the inverter avoids overvoltage trip by increasing the frequency.

Deceleration characteristic

(improved braking

capacity)

The motor loss is increased during deceleration to reduce the regenerative energy in the inverter

to avoid overvoltage trip.

Auto energy saving

operation

The output voltage is controlled to minimize the total sum of the motor loss and inverter loss at a

constant speed. (With digital input signal, auto energy saving mode can be turned ON or OFF by

an external device.)

Overload prevention

control

If the surrounding temperature or IGBT joint temperature increases due to overload, the inverter

lowers the output frequency to avoid overload.

Auto-tuning (offline) Tuning the motor while the motor is stopped or running, for setting up motor parameters.

Onine tuning *2, *3 Compensates for the change of motor parameters caused by temperature rise. *10

Cooling fan ON/OFF

control

• Detects inverter internal temperature and stops cooling fan when the temperature is low.

• The fan control signal can be output to an external device.

2nd to 4th motor settings

• Switchable among the four motors

• Code data for four kinds of specific functions can be switched (even during operation).

It is possible to set the base frequency, rated current, torque boost, and electronic thermal slip

compensation as the data for 1st to 4th motors.

Universal DI

The status of external digital signal connected with the universal digital input terminal is transferred

to the host controller.

Universal DO Digital command signal from the host controller is output to the universal digital output terminal.

Universal AO The analog command signal from the host controller is output to the analog output terminal.

Speed control *7 Notch filter for vibration suppression *9

Constant peripheral speed

control *4, *5

Controls the rotating speed to keep the peripheral speed (line speed) constant so that an increase

in the peripheral speed is suppressed.

*10

Synchronous operation *4,

*5, *7

Synchronizes the positioning of two motors.

*10

Pre-excitation *6, *7 Excitation is carried out to create the motor flux before starting the motor.

Zero speed control *7 The motor speed is held to zero by forcibly zeroing the speed command.

Servo lock *7 Stops the motor and holds the motor in the stopped position. *8

Torque control *6, *7

• Analog torque command input

• Speed limit function is provided to prevent the motor from becoming out of control.

*9

Rotational direction

limitation

Select either of reverse or forward rotation prevention.

Dew condensation

prevention

When the motor is stopped, current is automatically supplied to the motor to keep the motor warm

and avoid condensation.

Customized logic interface Available in 10 steps with the functions of 2-input, 1-output, logical operation, and timer function *9

Control

Battery-powered operation Drives the inverter in a low voltage status by the battery power. *11

*1 Available under V/f control.

*2 Available under dynamic torque vector control.

*3 Available when the slip compensation is made active under V/f control.

*4 Available under V/f control with speed sensor. (PG option required)

*5 Available under dynamic torque vector control with speed sensor. (PG option required)

*6 Available under vector control without speed sensor.

*7 Available under vector control with speed sensor. (PG option required)

*8 Available in inverters having a ROM version 0500 or later.

*9 Available in inverters having a ROM version 1000 or later.

*10 Available in inverters having a ROM version 3000 or later.

*11 Available in inverters having a ROM version 3600 or later.

Loading...

Loading...