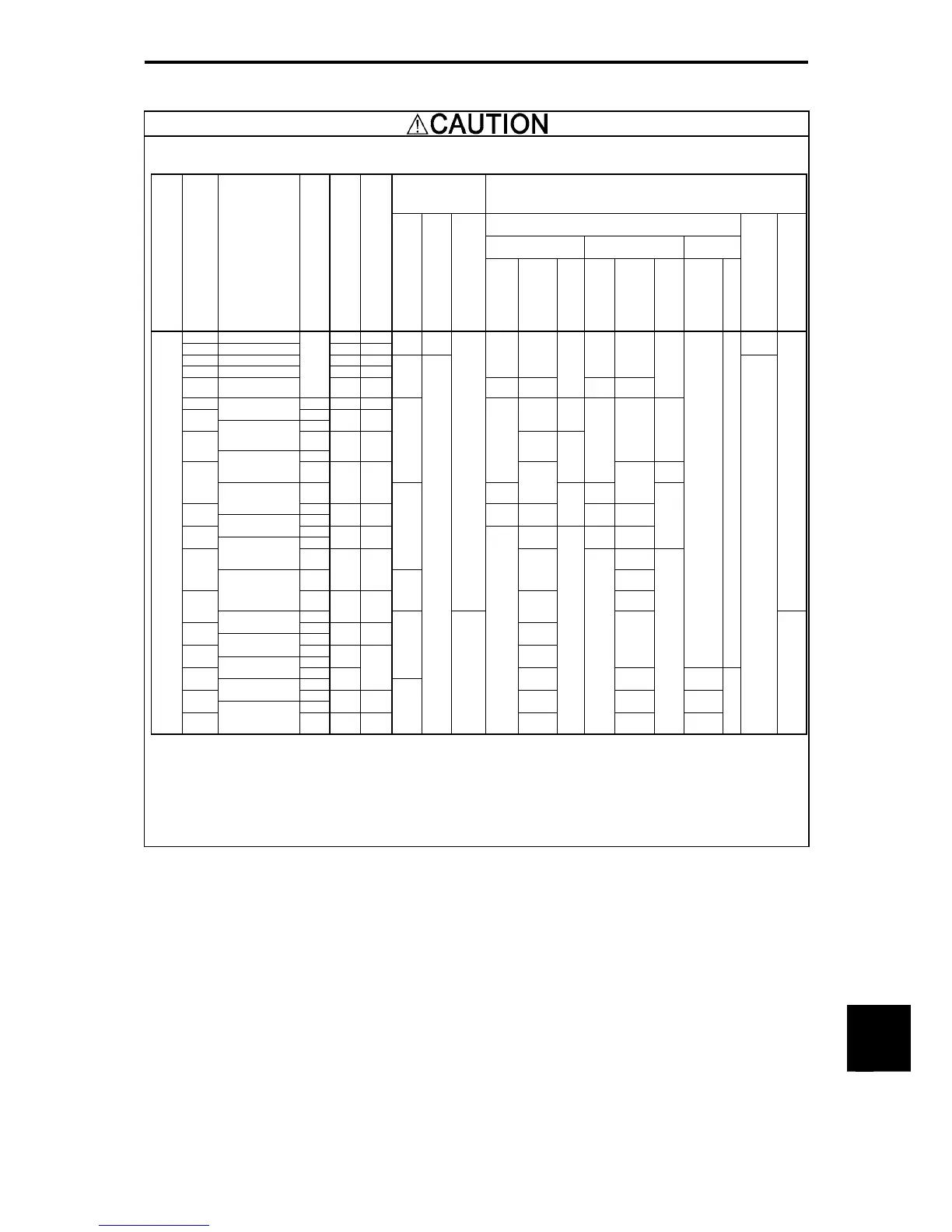

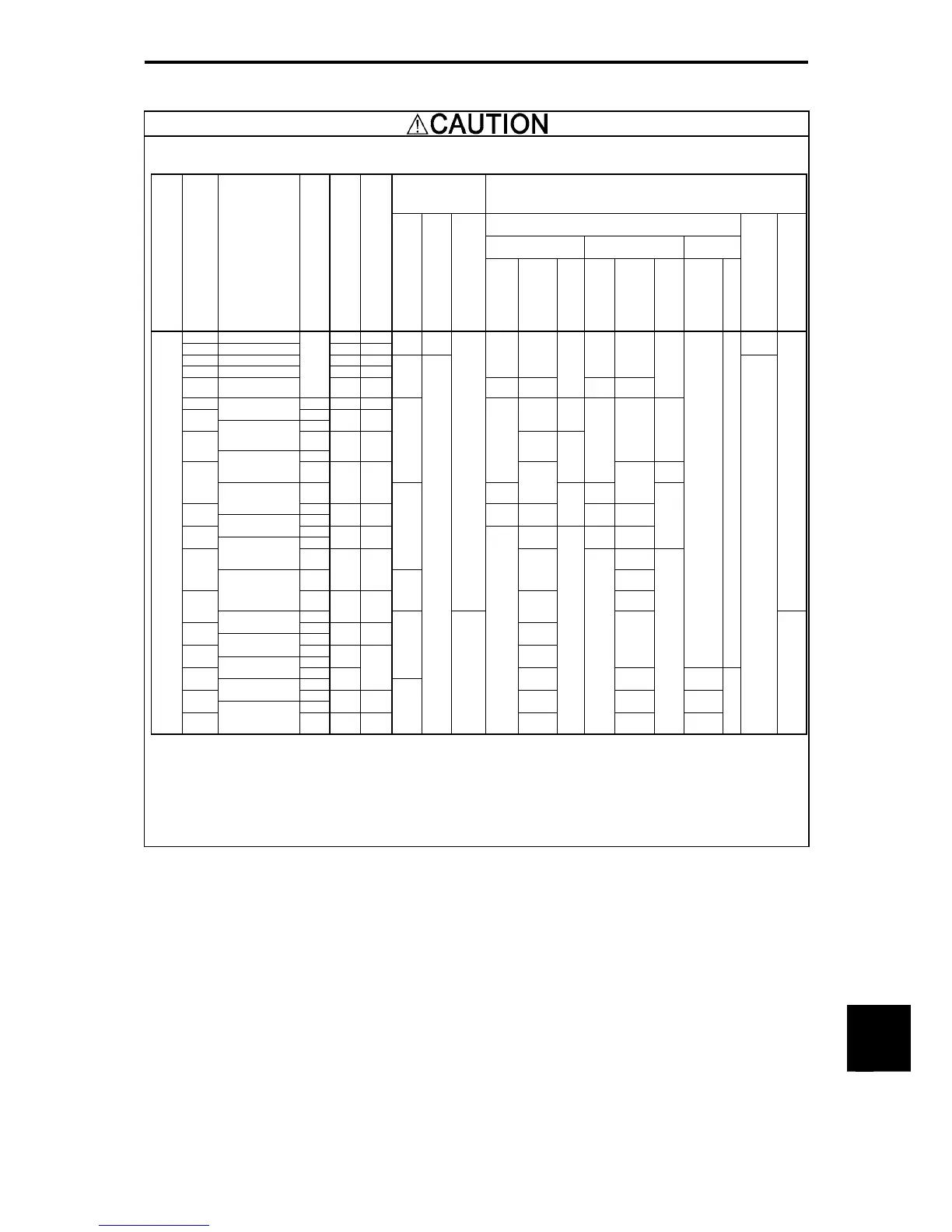

Chapter 13 COMPLIANCE WITH STANDARDS

Conformity with UL Standards and Canadian Standards (cUL certification) (cont.)

8. Install UL certified fuses or circuit breaker between the power supply and the inverter, referring to the table

below.

Required torque

lb-in (N・m)

Wire size AWG (mm

2

)

Main terminal Cu Wire

L1/R, L2/S, L3/T U, V, W P1, P(+)

Power supply voltage

Nominal applied motor

Inverter type

HD/LD mode

Class J fuse size (A)

Circuit breaker trip size (A)

Main terminal

Aux. control power supply

Aux. fan power supply

60ºC wire

75ºC wire

Remarks

60ºC wire

75ºC wire

Remarks

75ºC wire

Remarks

Aux. control power supply

Aux. fan power supply

0.4 FRN0.4G1-2J 10 5

0.75 FRN0.75G1-2J 15 10

10.6

(1.2)

-

―

1.5 FRN1.5G1-2J 20 15

2.2 FRN2.2G1-2J 30 20

14

(2.1)

14

(2.1)

14

(2.1)

14

(2.1)

3.7 FRN3.7G1-2J

HD

40 30

15.9

(1.8)

10

(5.3)

10

(5.3)

*1

12

(3.3)

12

(3.3)

*1

5.5 HD 60 50

FRN5.5G1-2J

LD

7.5

HD

75 75

8

(8.4)

*1

*2

*3

FRN7.5G1-2J

LD

11

HD

100 100

6

(13.3)

8

(8.4)

*1

*2

*3

FRN11G1-2J

LD

30.9

(3.5)

-

*2

*3

-

*2

*3

15

HD

150 125

3

(26.7)

4

(21.2)

4

(21.2)

6

(13.3)

FRN15G1-2

LD

18.5

HD

175 150

1

(42.4)

3

(26.7)

-

3

(26.7)

4

(21.2)

FRN18.5G1-2

LD

22

HD

200 175

2

(33.6)

2

(33.6)

3

(26.7)

-

FRN22G1-2J

LD

51.3

(5.8)

2

(33.6)

30

HD

250 200

2/0

(67.4)

1

(42.4)

FRN30G1-2J

LD

119.4

(13.5)

-

1/0

(53.5)

-

37

HD

350 250

3/0

(85)

FRN37G1-2J

LD

45

HD

400 300

4/0

(107.2)

FRN45G1-2J

LD

55

HD

450

2/0×2

(67.4×2)

4/0

(107.2)

―

―

FRN55G1-2J

LD

238.9

(27)

75

HD

500

350

3/0×2

(85×2)

3/0×2

(85×2)

4/0×2

(107.2×2)

FRN75G1-2J

LD

90

HD

600 400

4/0×2

(107.2×2)

4/0×2

(107.2×2)

300×2

(152×2)

Three-phase 200V

110

FRN90G1-2J

LD 700 500

424.7

(48)

10.6

(1.2)

10.6

(1.2)

-

300×2

(152×2)

*2

*3

-

300×2

(152×2)

*2

*3

400×2

(203×2)

*2

*3

14

(2.1)

*1

*2

14

(2.1)

(Note) Control circuit terminals Tightening torque: 6.1 lb-in (0.7 N・m), recommended wire size: AWG18 (0.8 mm

2

)

(Note) A box () in the above table replaces an alphabetic letter depending on the type.

*1 No terminal end treatment is required for connection.

*2 Use 75°C Cu wire only.

*3 The wire size of UL Open Type and Enclosed Type are common. Please contact us if UL Open Type exclusive wire is

necessary.

(To be continued)

Loading...

Loading...