2.2 Wiring

2-23

Chapter 2 INSTALLATION AND WIRING

Table 2.2-11

Classification

Symbol Name Functional description

(1)

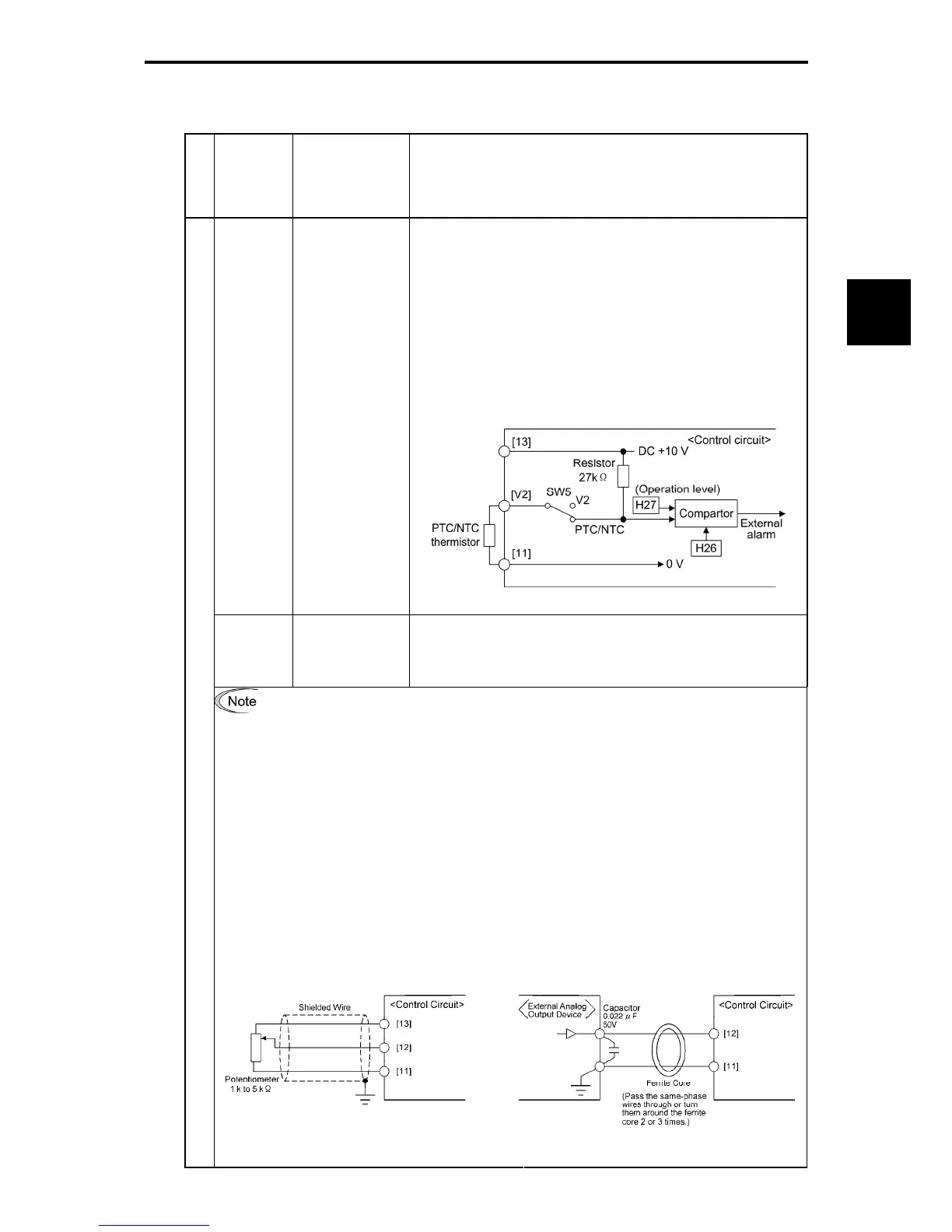

Connects PTC (Positive Temperature Coefficient)/NTC

(Negative Temperature Coefficient) thermistor for motor

protection. Ensure that the slide switch SW5 on the control

PCB is turned to the PTC/NTC position (refer to Section

2.2.7 "Setting up the slide switches").

The figure shown below illustrates the internal circuit

diagram where SW5 (switching the input of terminal [V2]

between V2 and PTC/NTC) is turned to the PTC/NTC

position. For details on SW5, refer to Section 2.2.7 "Setting

up the slide switches." In this case, you must also change

data of the function code H26.

[V2]

PTC/NTC

thermistor input

(PTC/NTC

function)

Figure 2.2-17 Internal Circuit Diagram (SW5 Selecting PTC/NTC)

[11]

Analog common

Common for analog input/output signals ([13], [12], [C1], [V2] and

[FMA]).

Isolated from terminals [CM] and [CMY].

-

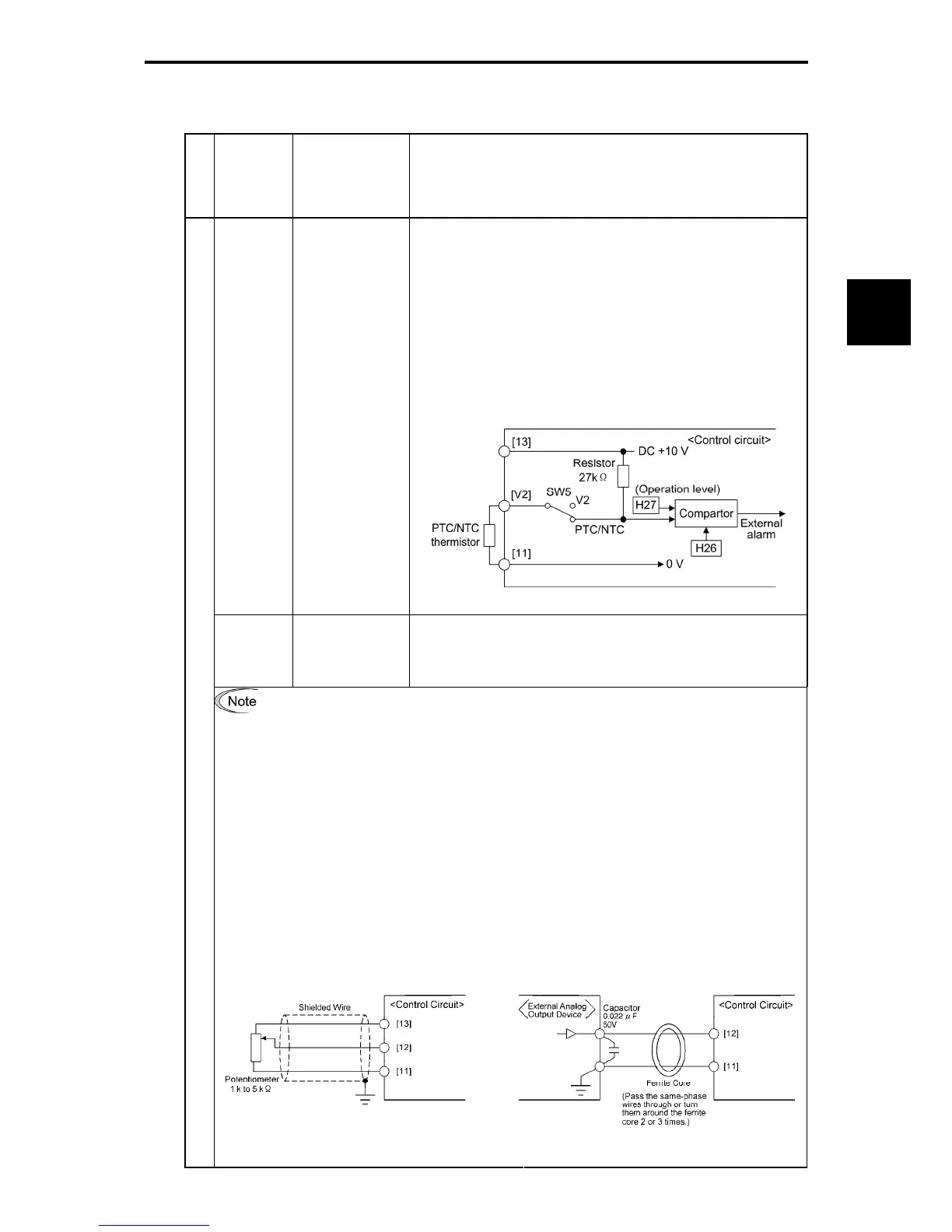

Since control signal wires are handled, these signals are especially susceptible to

the external noise effects. Route the wiring as short as possible (within 20 m) and

use shielded wires. In principle, ground the shielded sheath of wires; if effects of

external inductive noises are considerable, connection to terminal [11] may be

effective.

As shown in

Figure 2.2-18, be sure to ground the single end of the shield

to enhance the shield effect.

-

Use a twin-contact relay for low level signals if the relay is used in the analog input

signal wiring. Do not connect the relay's contact to terminal [11].

-

When the inverter is connected to an external device outputting the analog signal,

the external device may malfunction due to electric noise generated by the inverter.

If this happens, according to the circumstances, connect a ferrite core (a toroidal

core or equivalent) to the device outputting the analog signal or connect a

capacitor having the good cut-off characteristics for high frequency between control

signal wires as shown in Figure 2.2-19.

-

Do not apply a voltage of +7.5 VDC or higher to terminal [C1]. Doing so could

damage the internal control circuit.

Analog input

Figure 2.2-18 Connection of Shielded Wire Figure 2.2-19 Example of Electric Noise

Reduction

Loading...

Loading...