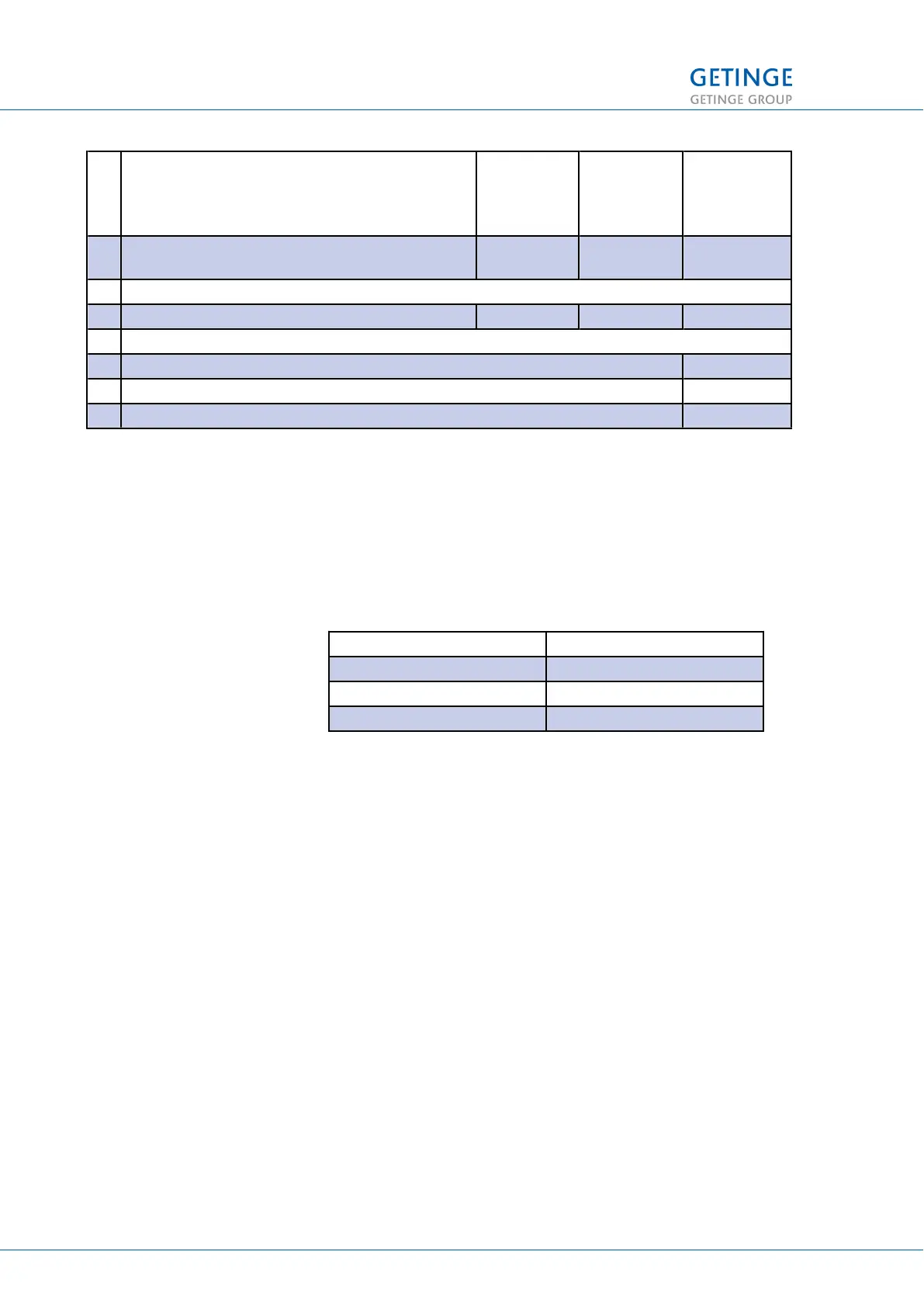

Activity/Component

Inspection/Replacement

Every year

/7500 cycles

Every other

year

/15000

cycles

Time

required

6.3 5.8.3 Checking the CPU card and the HEPA filter

6.3

• 10 min

7 Lighting

7.1 5.9.1 Checking lighting 7.1 • 5 min

8 Test run (at each service)

8.1 5.10.1 Function and leakage check 8.1

8.2 5.10.3 Temperature check 8.3

8.3 5.10.3 Temperature check 8.3

The time required is estimated with the top off and may vary

depending on the installation settings, operating conditions and

equipment level.

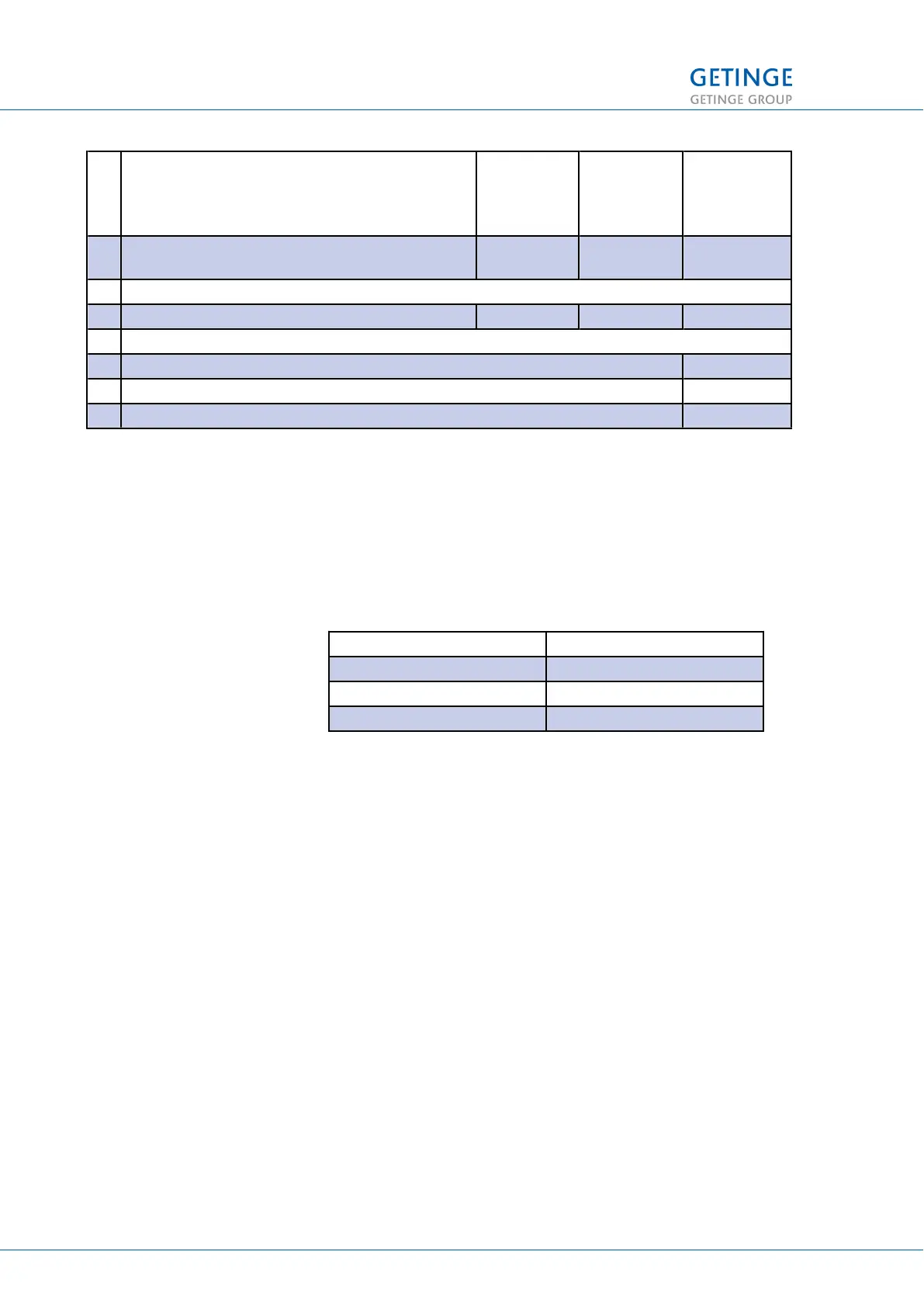

5.2 Consumables

The following consumables are necessary for preventive

maintenance and are not covered by product warranty. For article

numbers, see the spare parts list.

Consumables Section

Hose in dosing pump 6. Dosing system

Transport hose 5x8 6. Dosing system

HEPA filter 8. Ventilator

5.3 General (Item 1)

5.3.1 Checking electrical cables and connection points 1.1

The purpose of checking the cabling and connection points is

primarily to avoid personal injury as well as damage to the machine

itself.

1. Check that the power cord to the electrical unit is intact, free

of errors and installed as per the instructions.

2. Check that all cables are connected to the terminal block for

the technical unit.

3. Check that there are no non-insulated unconnected cables by

the technical unit.

4. Check to ensure that connections on connecting cables are

tightened.

5. Check that the isolator switch on the wall is working and that

the connecting cable is undamaged and free from defects.

5 PREVENTIVE MAINTENANCE

62 (128) TECHNICAL MANUAL GETINGE WD15 CLARO

<Doc_TEC><Doc_6001396902><Rev.I><Lang_en>

Loading...

Loading...