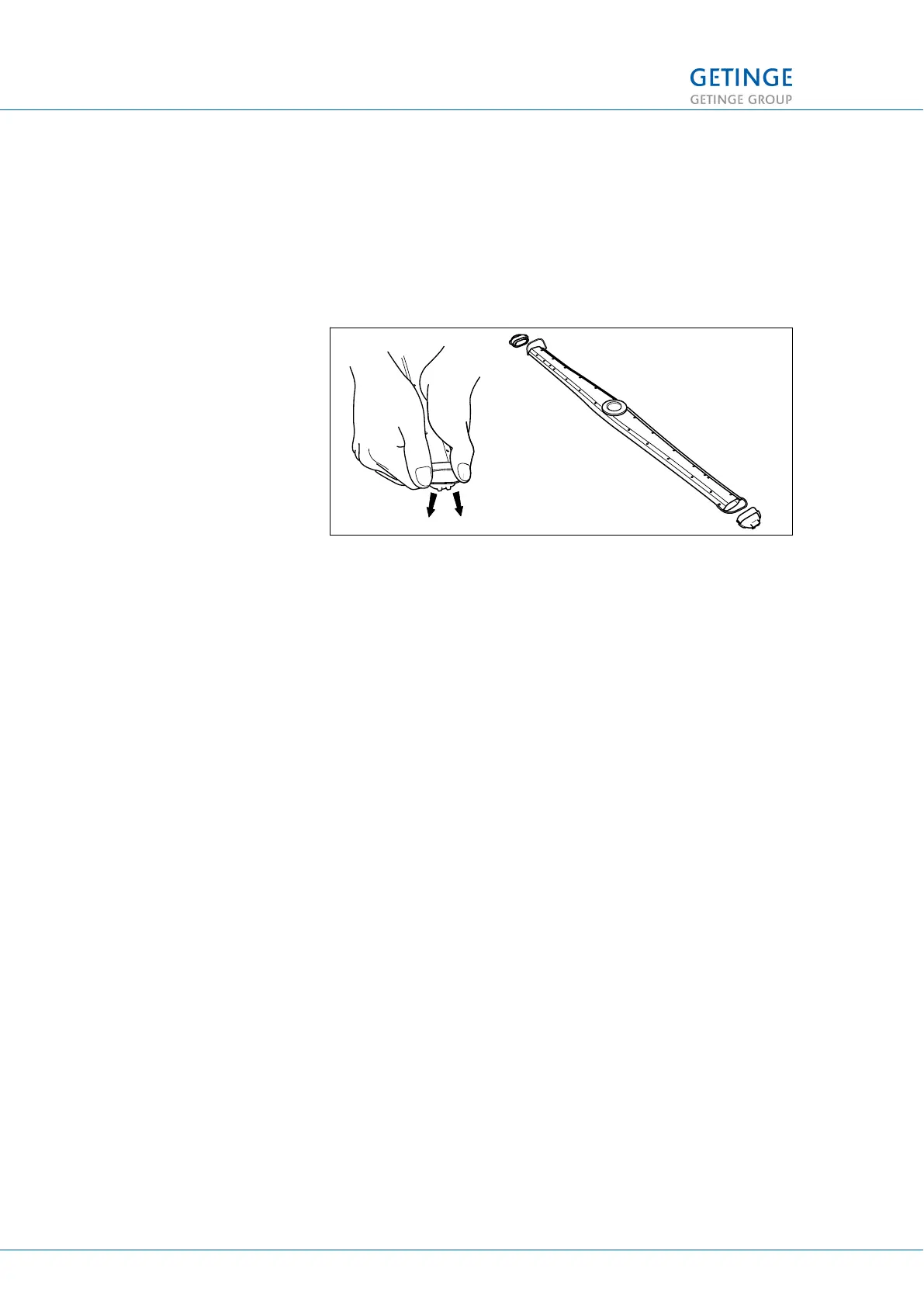

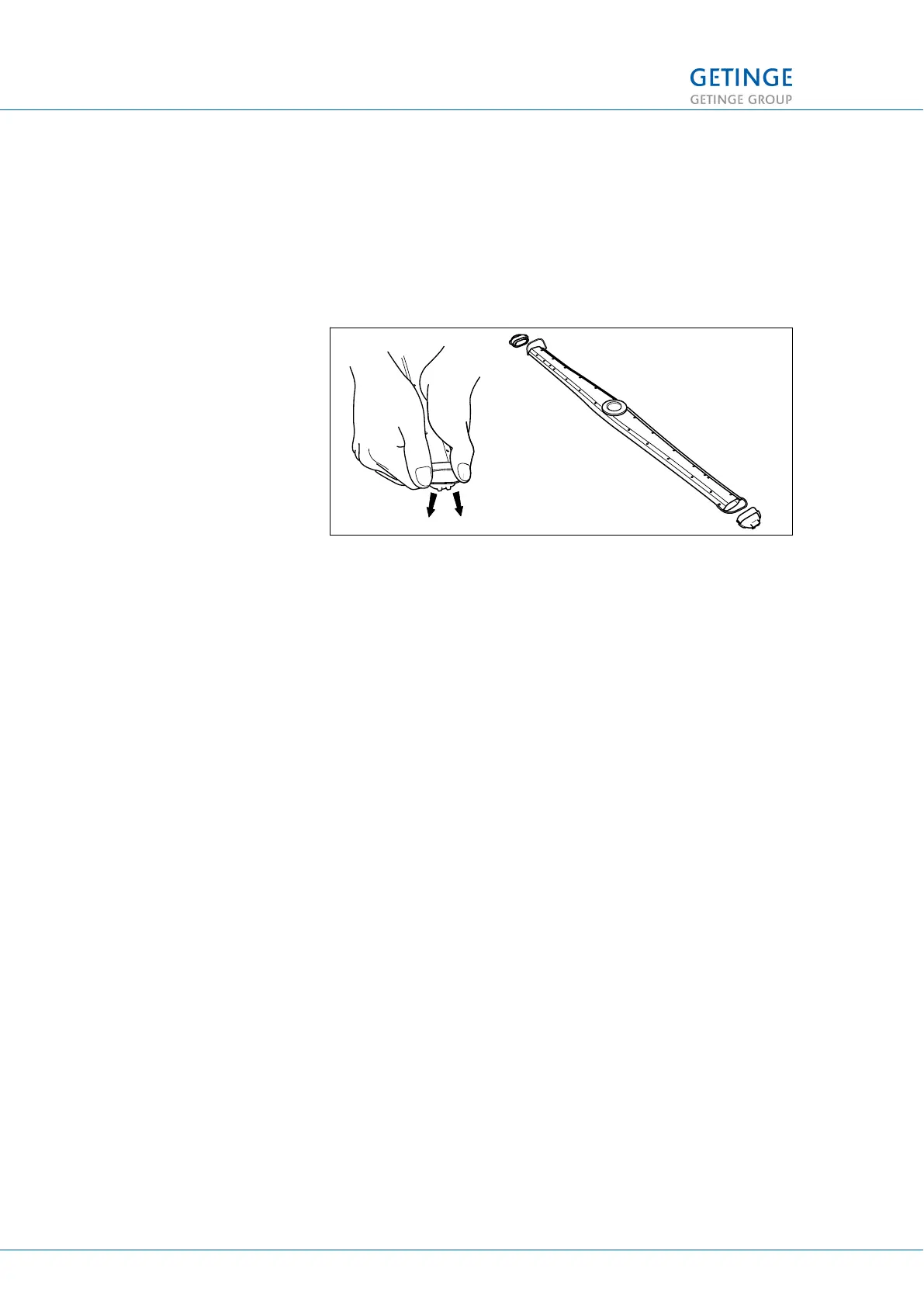

5.4.2 Check the spray arms 2.2

• Check that all spray arms are correctly fitted.

• Check that the spray arms can rotate freely.

• Check that the holes in the spray arms are not blocked. Clean

as required.

• Check that the end plugs of the spray arm are correctly fitted.

Figure 6. Checking spray arm

5.4.3 Replacing spray arm bearings 2.3

If you need to replace the bearings on the spray arms that are

installed in the chamber, a replacement interval of every other year

is recommended.

5.4.4

Checking temperature sensors 2.4

This inspection is performed to check that the temperature sensor

is working and that the lead-in on the top of the chamber is tightly

sealed. Failure to perform an inspection can result in inadequate

disinfection and leakage. If the temperature in the machine is off by

more than ± 1 °C, the temperature sensor must be recalibrated.

For further instructions see 5.10.1 Function and leakage check

8.1 .

5 PREVENTIVE MAINTENANCE

64 (128) TECHNICAL MANUAL GETINGE WD15 CLARO

<Doc_TEC><Doc_6001396902><Rev.I><Lang_en>

Loading...

Loading...