7 Sensor configuration

44 PHLOX II Ignition Control System

Entering the number 0 in the assignment parameter signifies that the respective sensor has

neither been connected nor activated. Consequently, the input will not be monitored. The

assignment parameters of any sensors which are not required should therefore be set to 0.

The sensor value during operation will then constantly be equal to the minimum value.

Double assignments will not be intercepted. But the HEINZMANN communica-

tions programme DcDesk 2000 reports such multiple configurations in its sen-

sor window.

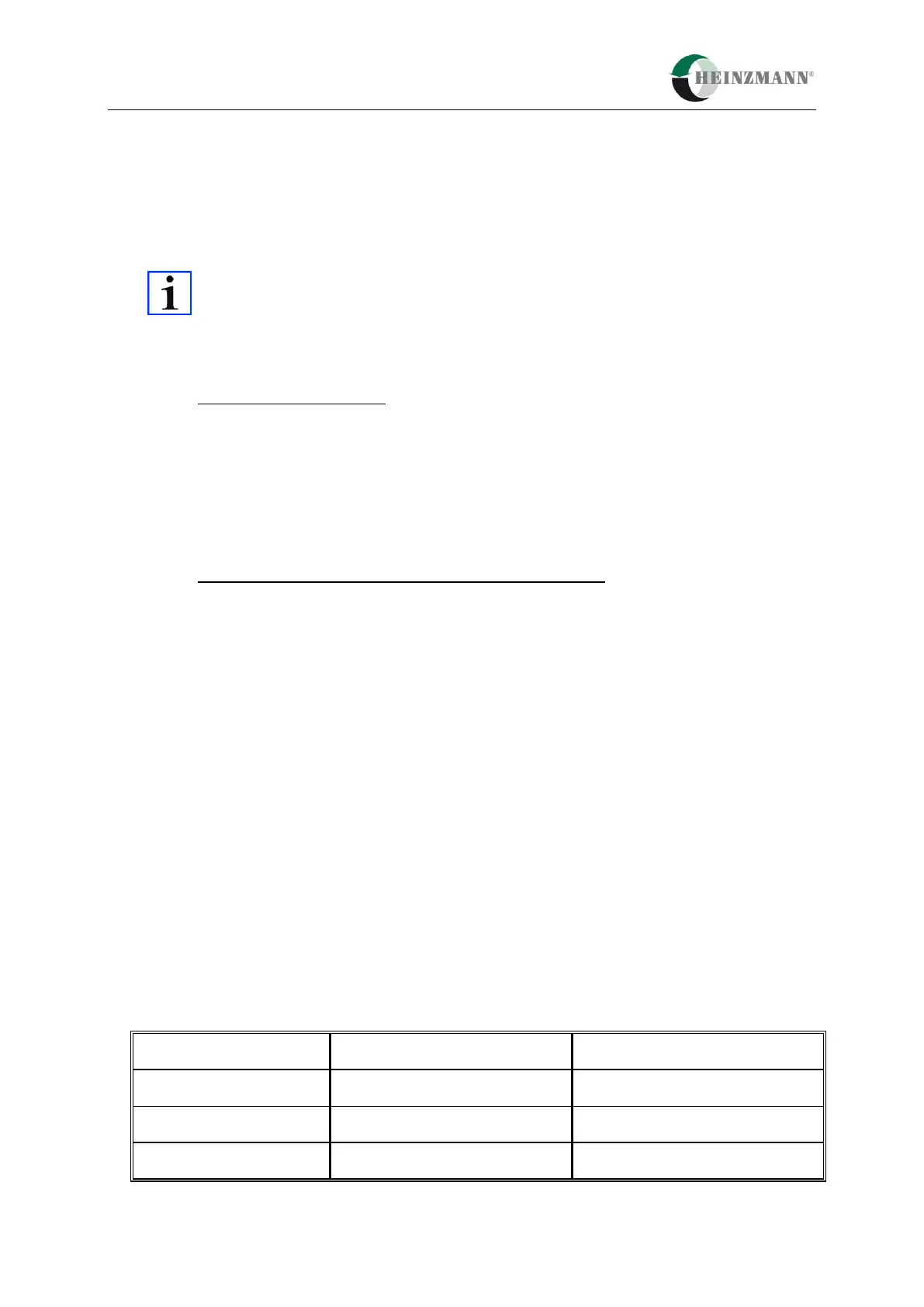

Parameterising Example:

The ignition timing offset adjuster (indication parameter 2900) is to be connected

to the analogue input, the ignition energy offset adjuster (indication parameter

2901) to PWM input 1, and the manifold pressure sensor (indication parameter

2912) to HZM-CAN customer module input 3. For all other sensors which remain

unused the value 0 is to be entered.

Number Parameter Value Unit

900 AssignIn_IgnTimOffs 1

901 AssignIn_IgnEgyOffs 1

912 AssignIn_MnfldPress 3

4900 ChanTypIgnTimOffs 0

4901 ChanTypIgnEgyOffs 1

4904 ChanTypMnfldPress 8

7.4 Measuring ranges of sensors

In HEINZMANN controls, all sensor parameters and all relating values are provided with

the maximum possible value range. For example manifold pressure covers a maximum

range of 0 to 5 bar.

Since pressure sensors exist with different measuring ranges, the control unit must be in-

formed of the particular value ranges which may differ from the maximum possible physi-

cal value range. These ranges are defined as the physical values corresponding to minimum

and maximum input values such as 0.5 to 4.5 Volts or 4 to 20 mA for analogue inputs or

10 % and 90 % for PWM inputs.

Loading...

Loading...