OPERATING INSTRUCTIONS

7.4

ThinPrep™ 5000 Processor with AutoLoader Operator’s Manual

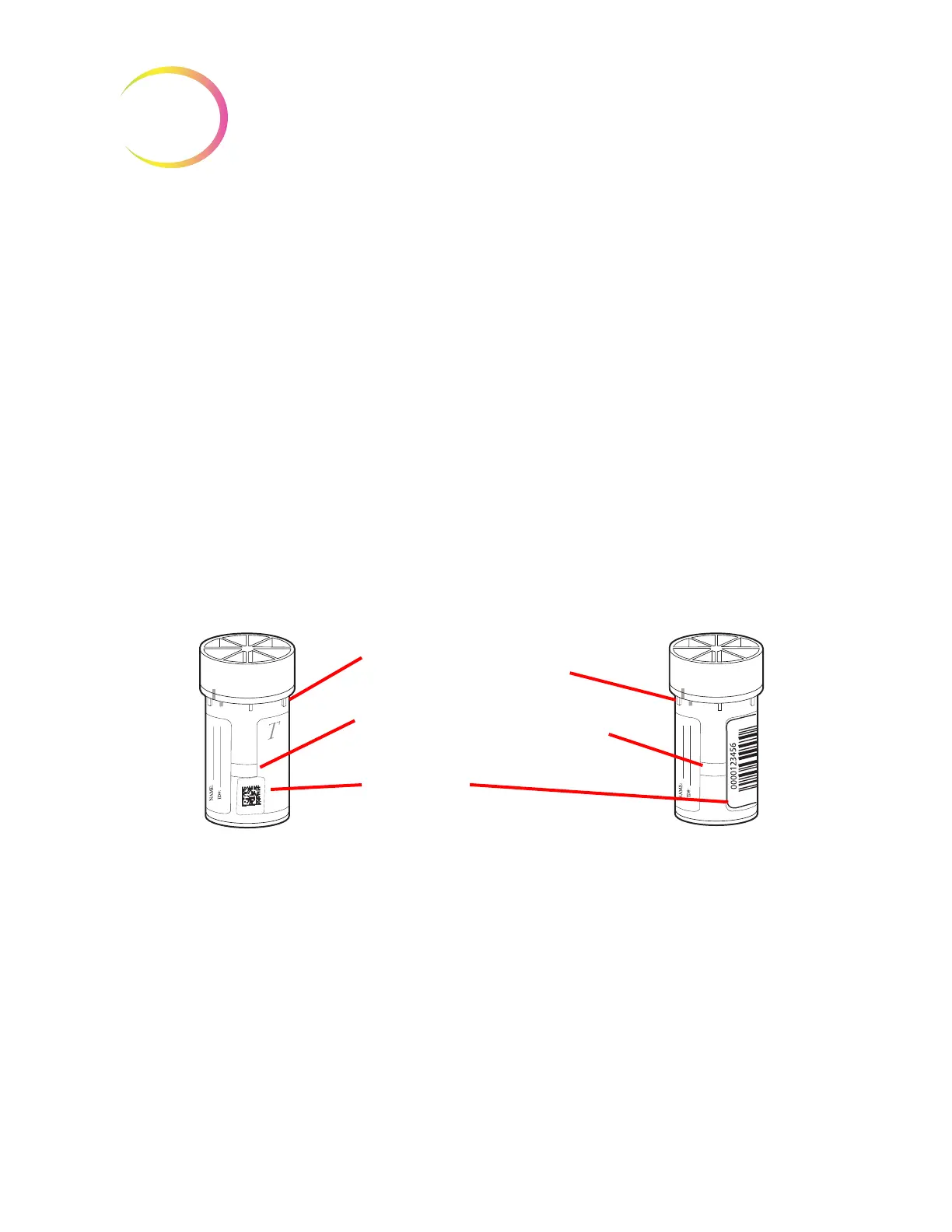

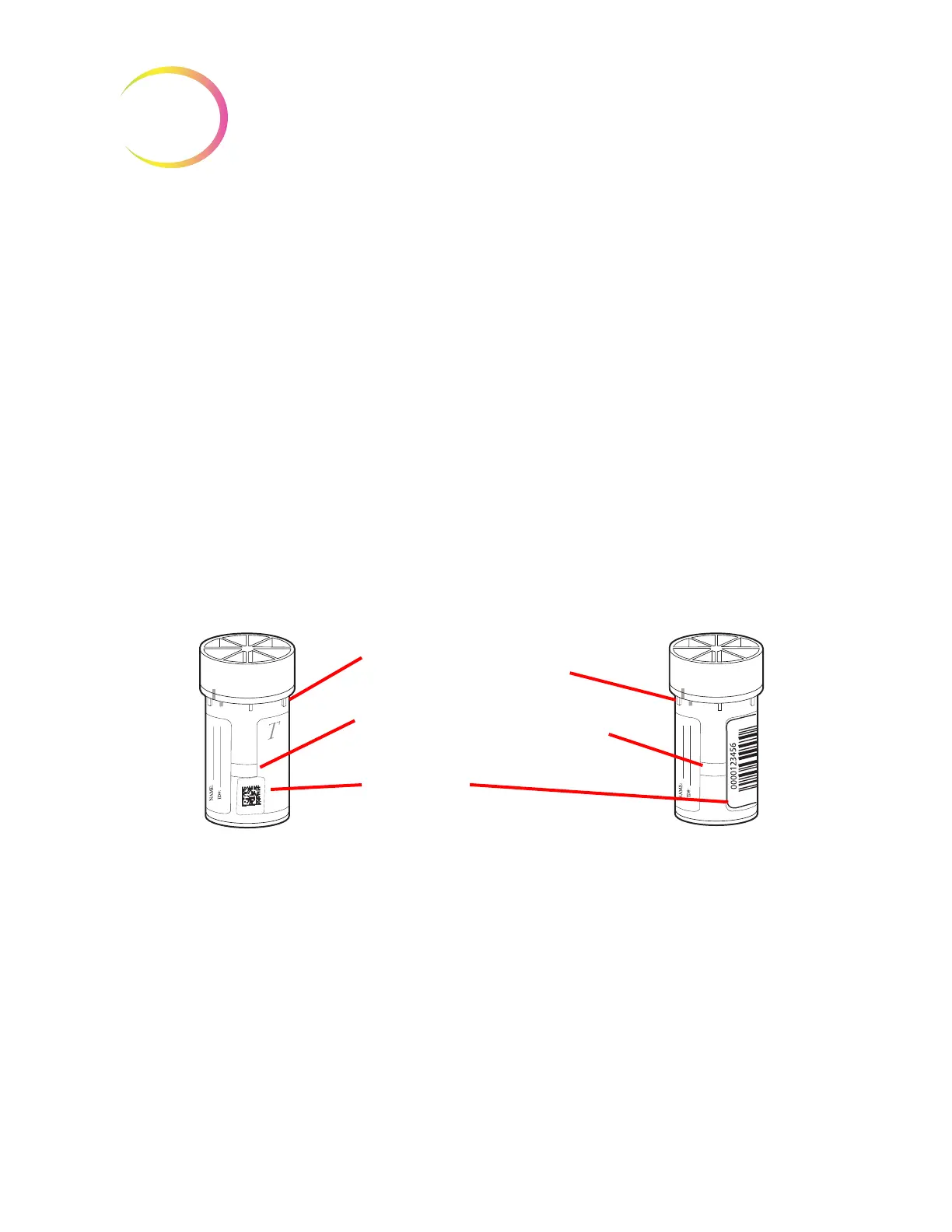

Adhering Vial Labels

Place a vial label with a 1-D barcode

vertically

on the PreservCyt™ Solution label, using the edge for

alignment, as shown in Figure 7-2. A crooked label, skewed 10 degrees or more from vertical, may

not scan properly.

Place a vial label with a 2-D barcode in the lower third of the vial, between 20 mm (0.80 in.) and

5 mm (0.20 in.) from the bottom of the vial, close to but not covering the frosted area of the vial. For

the ThinPrep 5000 processor to properly read the 2-D barcode, do not put any other 2-D barcode label

on the vial.

During application, avoid placing the barcode label over patient information, multiple labels, or on

the torque features of the vial. Do not place labels on the vial cap or on the bottom of the vial.

Sticking labels on incorrectly can cause a failure to read the barcode or a failure of the instrument

removing the vial from the carousel.

The uncovered strip of the sample vial allows you to see the frosted band which indicates the

maximum/minimum acceptable fluid fill range for a sample to be run on the processor. Make sure

the fluid level is within this range.

Additionally, check to make sure there is no foreign matter in the vial (such as a piece of sample

collection device or other non-biologic debris).

Figure 7-2 PreservCyt Solution Sample Vial

Torque tab features enable the processor

to uncap / recap the vial

Frosted area indicates min./max.

acceptable fluid level for processing

(17 mL–21 mL)

Barcode label

P A P

Loading...

Loading...