8

INFORMATION ABOUT OVERHAULING

EN 106

Tab 8.6

0.025 - 0.030

Important

•

Tab. 8.6 details the dimensional values of new

components only.

•

Check that the connecting rod and crankshaft half-

bearings are coupled properly.

•

Refer to the warnings in Par. 8.4.1 for value D

decreased.

•

If the clearance value between B and C is not observed,

you are required to replace bearing R (Fig. 8.12).

Measure value

A, C, D, E and F

and confront them with those

described in

Tab.8.6

.

If the measured values do not follow those described in

Tab.8.6

,

replace connecting rod

T

.

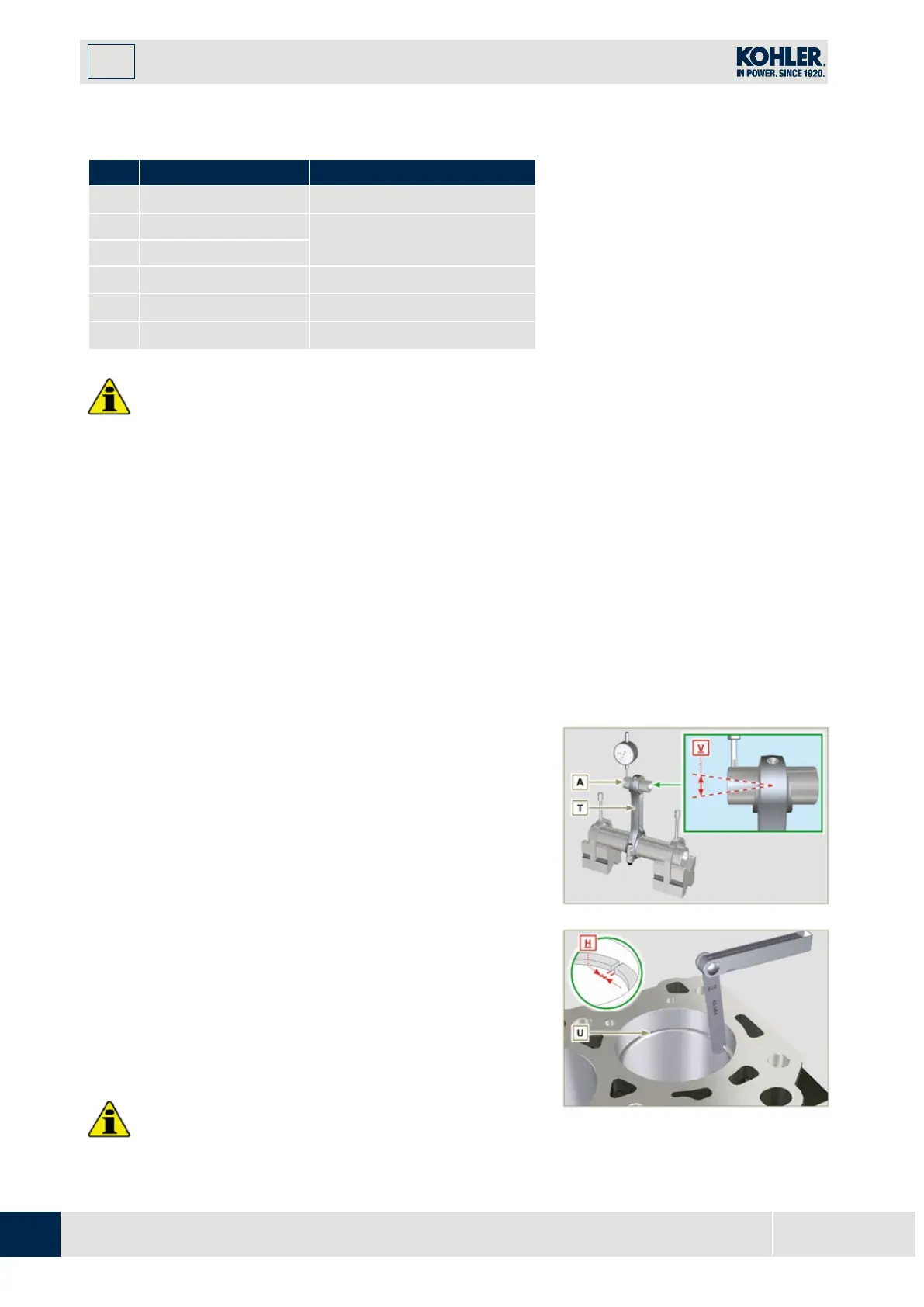

8.5.2 Checking the gudgeon pin-pin axes are parallel

Lubricate gudgeon pin

A

and bearing

R (Fig. 8.12)

.

Insert the gudgeon pin into bearing

R

. Use a dial gauge to check

the axis parallelism of the connecting rod big end and small

end.

Parallel deviation (value V) measured at the tip of the

gudgeonpin, must be a MIN of 0,015 and MAX of 0,030 mm.

If the parallelism values do not comply with the specified

ones,replace the connecting rod with a new one.

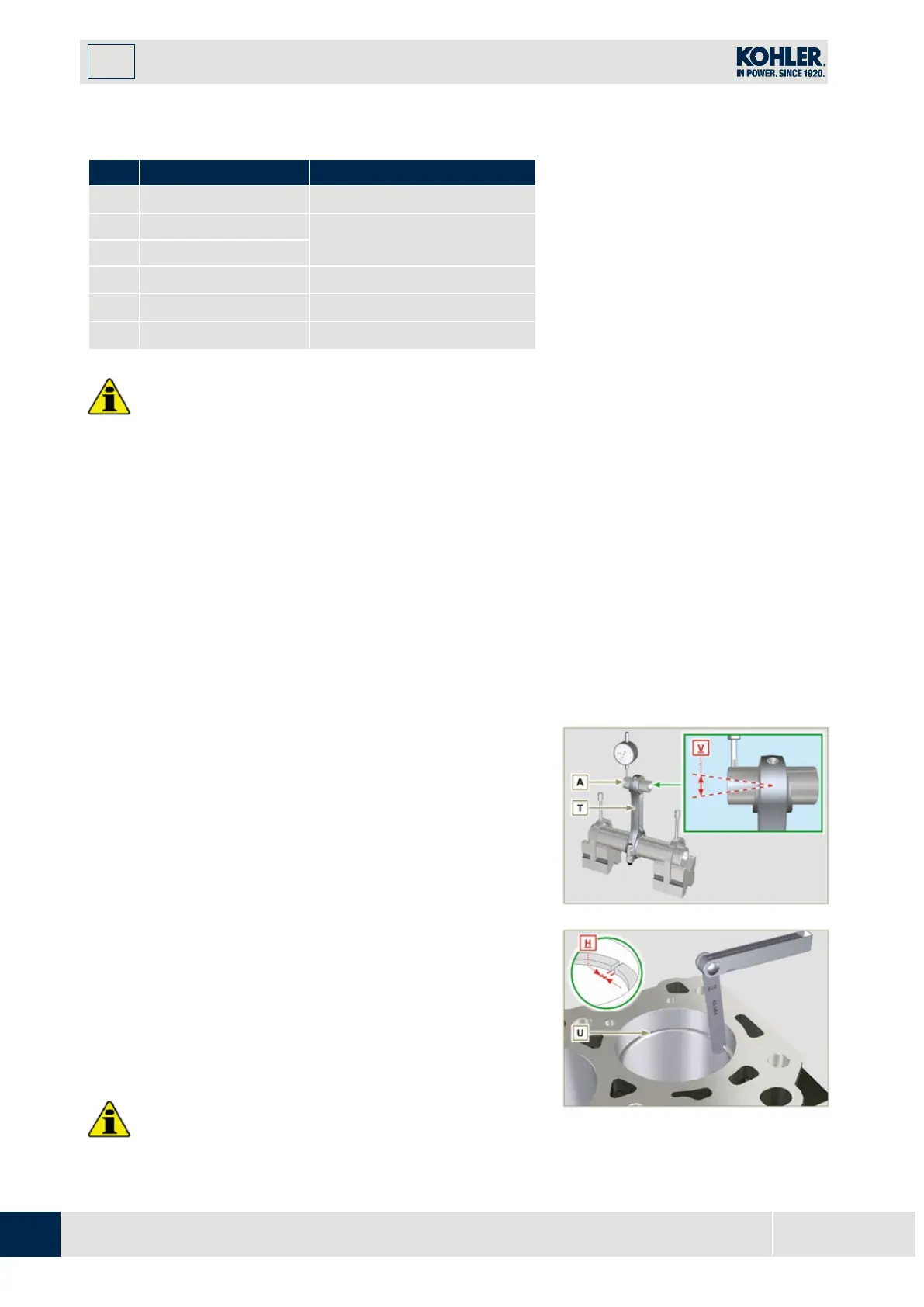

8.

5.3

Piston rings check

Insert ring

U

into the cylinder, measure value H (distance

between the points of ring

U

).

Repeat for all the seal rings.

If the measured value H does not correspond to the values

indicated in the table (Tab. 8.7), replace the seal rings U.

Important

Fig 8.14

Fig 8.15

Loading...

Loading...