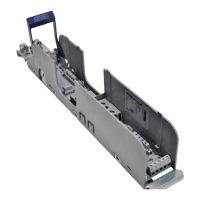

9300 Servo PLC

Appendix

4-3

9300ServoPLC EN 1.4

4.3 Monitoring

System interfaces

• System bus (CANopen)

• Field buses

• Digital frequency,

analog and digital I/O

CAN

Microcontroller

Digital

Signal

Processor

(FLASH, EEPROM, RAM)

• PLC application program

to IEC 1131-3

(can be changed)

Technology functions

• Operating system

• Communication

• Drive control

(cannot be changed)

• Motor control

Rectifier

Inverter

Asynchronous motor

with resolver / encoder

Standard motor

Synchronous motor

SIN/COS encoder

Memory

The Servo PLC 9300 includes two independent parts:

• Motor control and

• PLC.

Tip!

In general, faults do not affect the serviceability of the PLC!

Different monitoring functions of the motor control protect the drive from unpermissible operating

conditions.

After the monitoring function has been triggered

• the corresponding set reaction is released (see chapter 4.3.1).

• a digital output of a system block is set.

In the event of undervoltage at the PLC, for instance, the output

MCTRL_bUndervoltage_b

of

the system block MCTRL_MotorControl (internal motor control) is set to TRUE (see

(

^

2-57)).

• the error code is entered in the history buffer.

• the current error number is displayed under DCTRL_wFaultNumber.

If a reaction on a motor control error is required, the error can be requested (see description of the

individualsystem blocks).ThesystemblockDCTRL_DriveControldisplaysthat anerrorhasoccured

and shows the current error code.

Loading...

Loading...