9300 Servo PLC

Connection

3-4

9300ServoPLC EN 1.4

3.1.2.1 System bus wiring complying to EMC

K1

K1

L3

N

PE

L1

L2

U

V

W

L1 L2

L3

F1

932X - 933X

PE

+UG -U G

PE

Z1

K1

U

V

W

L1 L2 L3

932X - 933X

PE

+UG -U G

PE

Z1

F1

ON

OFF

28

A4

PE

28

A4

RFR

PE

U

V

W

L1 L2 L3

932X - 933X

PE

+UG

-U G

PE

Z1

F1

28

A4

PE

RFR

RFR

GND

HI

LO

GND

HI

LO

RA2

GND

HI

LO

RA1

F2 F3 F2 F3 F2 F3

7

7 7

9300PLC123

1. Every device in the system bus must have a good PE connection.

2. Control cabinets, which include bus devices should be interconnected by a separate

equipotential bonding cable.

3. Motor cables should be screened; connect the screen to both ends:

–atthemotor

– at the controller.

Attach the screen using the supplied clamps to the screen sheet or to the conducting

mounting plate of the control cabinet. This means that the cable is stripped in the contact

area of the clamp thus providing a large-surface contact to the clamp and to PE.

4. Select system bus cables according to the specification in the Tab. 3-1.

– Connect the screen at both ends.

– Attach using the supplied screen plate:

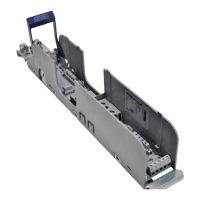

K35.0021

Strip cable in the contact area of the clamp and make a large-surface contact to the clamp

and to PE.

5. Connect terminating resistor R

A

= 120Ω at the physical bus ends.

6. Separate control and fieldbus cables from the motor cable!

7. The CAN-GND cable must also be separated from the motor cable.

8. Connect terminal 7 with the screen plate of the controller.

9. Avoid stubs

Loading...

Loading...