9300 Servo PLC

Appendix

4-11

9300ServoPLC EN 1.4

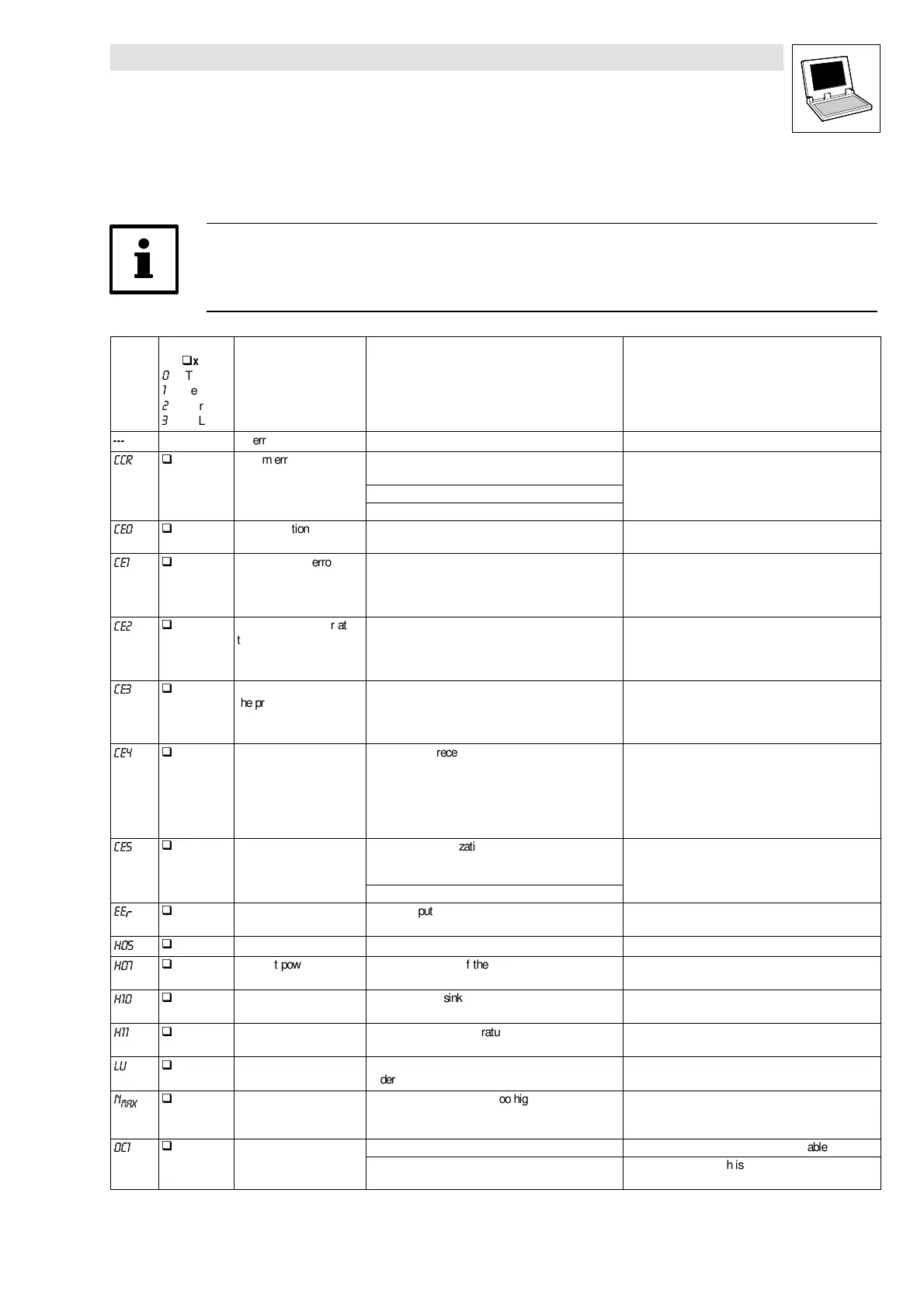

4.7 Error messages

Tip!

If the error message is requested by a fieldbus, the fault indication is represented by a fault number

(C0168/x). See column 2and the footnote at the end of this table.

Display

Error no.:

q

xxx

-TRIP

- Message

- Warning

-FAIL-QSP

Error Cause Remedy

--- No error - -

&&5

q

071 System error

The program sequence of the processor was

interfered.

Sc

een c

nt

landm

t

cables as necessa

.

Strong interference on control cables

.

Check PE wiring and PE connections.

Ground or earth loops in the wiring

&(

q

061 Communication error Interference during transmission of control

commandsvia automation interface X1

Plug in automation module firmly, bolt down, if

necessary

&(

q

062 Communication error at

the process data input

object CAN_IN_1

CAN_IN_1 object receives faulty data, or

communication is interrupted

• Check cable at X4

• Check transmitter

• Increase monitoring time under C0357/1 if

necessary

&(

q

063 Communication error at

the process data input

object CAN_IN_2

CAN_IN_2 object receives faulty data, or

communication is interrupted

• Check cable at X4

• Check transmitter

• Increase monitoring time under C0357/2 if

necessary

&(

q

064 Communication error at

the process data input

object CAN_IN_3

CAN_IN_3 object receives faulty data, or

communication is interrupted

• Check cable at X4

• Check transmitter

• Increase monitoring time under C0357/3 if

necessary

&(

q

065 BUS-OFF state Controller has received too many incorrect telegrams

viasystem bus X4, and has disconnected from the bus

• Check wiring

• Check bus termination (if any)

• Check screen contact of the cables

• Check PE connection

• Check bus load

• Reduce baud rate (observe cable length)

&(

q

066 CAN Time-Out

For tele-parameterization via system bus (C0370):

Slave does not respond.

Communication monitoring time exceeded.

• Check wiring of the system bus

• Check system bus configuration

For modem operation on FIF: Internal error

u

u

((

q

091 External fault (TRIP-Set) A digital input assigned to the TRIP-Set function has

beenactivated.

Check external encoder

+

q

105 Internal error Contact Lenze

+

q

107 Incorrect power stage During initialization of the controller, an incorrect

power stage wasdetected

Contact Lenze

+

q

110 Sensor fault: heat sink

temperature

Sensor for heat sink temperature detection

indicatesindefinite values

Contact Lenze

+

q

111 Sensor fault indoor

temperature

Sensor for indoor temperature detection indicates

indefinite values

Contact Lenze

/8

q

030 Undervoltage DC bus voltage is smaller than the value fixed

underC0173

• Check mains voltage

• Check supply cable

1

0$;

q

200 Max. plant speed

exceeded (C0596)

Active load (e.g. for hoists) too high

Drive is not speed-controlled, torque excessively

limited.

Check drive dimensioning.

Increase torque limit if necessary.

2&

q

011 Short circuit

Short-circuit. Find out cause of short-circuit; check cable.

Excessive capacitive charging current of the motor

cable.

Use motor cable which is shorter or of lower

capacitance.

Loading...

Loading...