9300 Servo PLC

Connection

3-1

9300ServoPLC EN 1.4

3Networking

8200DPL001

The production factor ”information” becomes increasingly important for the networking of

production plants. This applies particularly to a drive network and automation of decentralized

drives.

Drives of the Lenze range can easily be networked and implemented into a comprehensive

automation concept.

The control and parameterization of the devices can be carried out, depending on the task, using

different communication interfaces:

• terminals (analog, digital, digital master-frequency)

• built-in system bus interface (CAN)

• plug-in field module for the following bus systems or communication profiles

– RS232/485 {LECOM-A/B/LI} with or without optical fibres (type 2102)

– INTERBUS (type 2111)

– INTERBUS-Loop (type 2112)

– PROFIBUS-DP (type 2131 and 2133)

– DeviceNet/CANopen (type 2175)

• plug-in operating module (keypad).

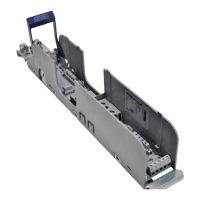

Thecommunicationtohigher-levelhostsispossibleviaasimpleplug&playinterfaceatthefrontside

of the device.The above figure shows such a communication with fieldbus modules 2133

PROFIBUS-DP.

Inanexisting connection viafield busmodulesto ahigher-level mastersystem thesystem bus (CAN)

can additionally be used for communication between Lenze devices. Time-critical data such as

setpoint and actual values, can be exchanged in real-time using the system bus.

Special handling features of the system bus (CAN):

• simple communication

• no special knowledge of bus systems required.

Loading...

Loading...