Slic3r

Infill Optimization

Slic3r contains several advanced inll settings which can help produce

better extrusions.

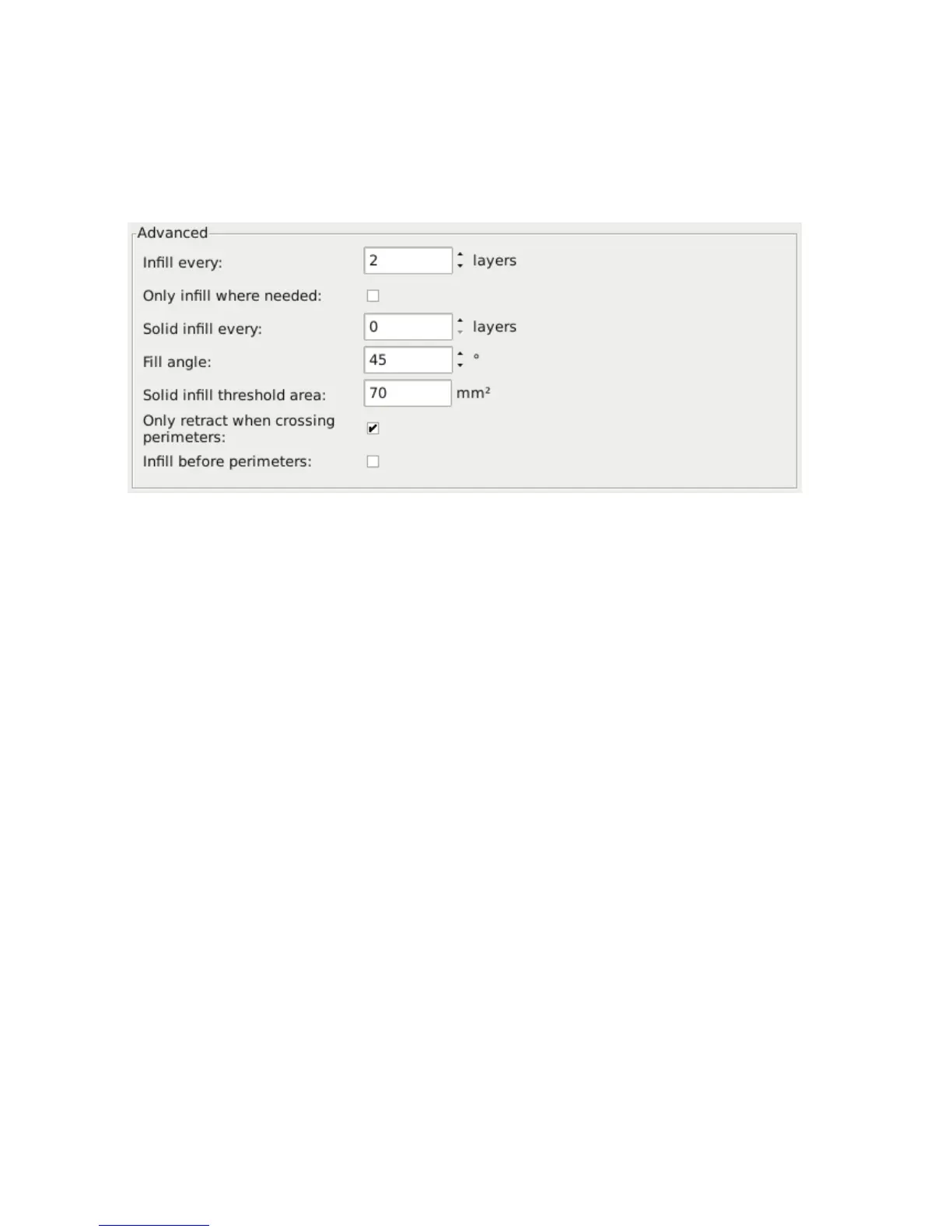

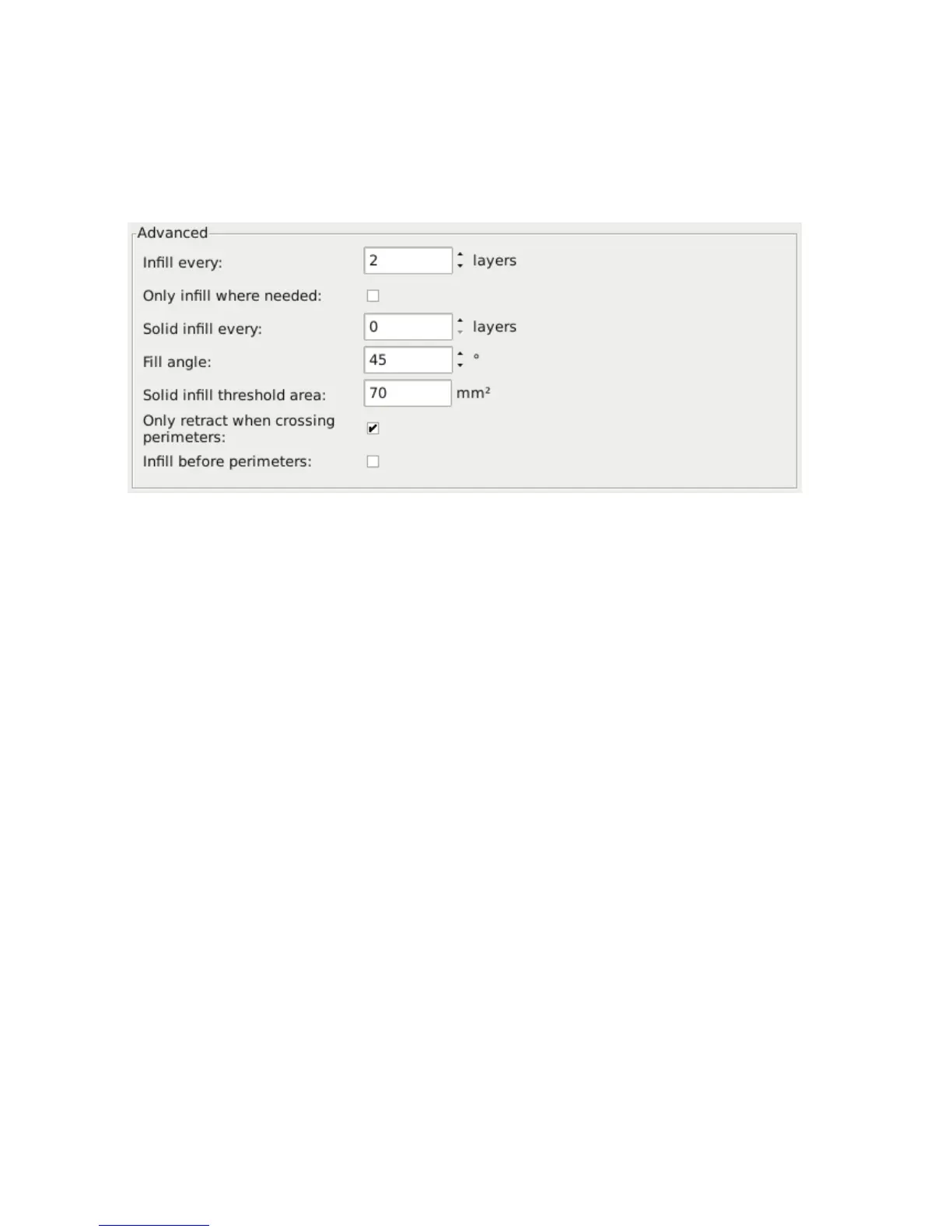

Figure 2.32: Inll advanced settings.

• Infill every n layers - Will produce sparse vertical inll by

skipping a set number of layers. This can be used to speed up print

times where the missing inll is acceptable.

• Only infill where needed - Slic3r will analyse the model and

choose where inll is required in order to support internal ceilings

and overhangs. Useful for reducing time and materials.

• Solid infill every n layers - Forces a solid ll pattern on the

specied layers. Zero will disable this option.

• Fill angle - By default the inll pattern runs at 45° to the model to

provide the best adhesion to wall structures. Inll extrusions that run

adjacent to perimeters are liable to de-laminate under stress. Some

models may benet from rotating the ll angle to ensure the optimal

direction of the extrusion.

• Solid infill threshold area - Small areas within the model are

usually best o being lled completely to provide structural integrity.

This will however take more time and material, and can result in

96

Loading...

Loading...