9HUVD3XOVH3RZHU6XLWH6HULHV6HUYLFH0DQXDO &$/$'-867$/,*1

5(9%

3.4.2 Blastshield Sense Switch Adjustment

Perform this procedure if the blast shield has been inserted

and the INSERT DEBRIS SHIELD message remains ON.

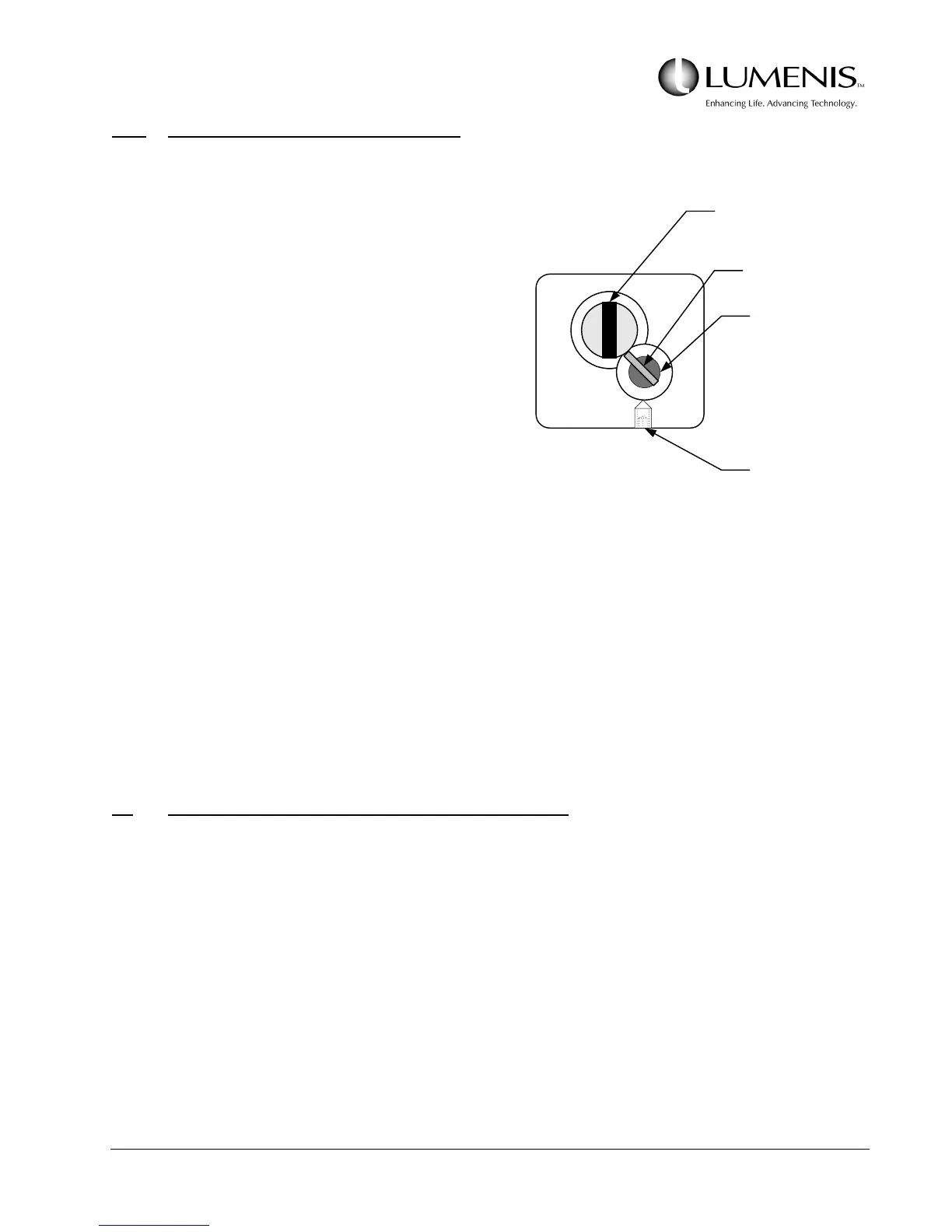

Refer to Fig. 3.11.

1. Open the front door and remove the blastshield access

door from the front door; locate LED11 on the Control-

ler PCB or connect a DVM across TP50 (BLST) and

TP46 (GND).

2. Reach around the right side of the laser head casting

and locate the blastshield; remove the blastshield.

3. Adjust the blastshield switch.

The blastshield switch is located behind the blast-

shield alignment pin. Loosen the set screw securing

the blastshield sensing switch and adjust the switch so that LED11 comes ON or TP50 goes HIGH on

the DVM just before the blastshield is fully seated in the detent.

a. If LED11 comes ON with more than 2mm of travel before the blastshield snaps into the detent,

loosen the set screw and slightly push the blastshield switch IN to the casting and recheck.

b. If LED 11 does not come ON or intermittently comes ON when in the detent position, loosen the set

screw and pull the blastshield switch OUT of the laser head casting and recheck.

3.5 ENERGY MONITOR AND AUTO CALIBRATION

The energy monitor calibration procedure adjusts energy monitor amplifier circuit gains to establish a

conversion factor in terms of Volts/Joule by referencing delivered Holmium and Nd:YAG laser energy as

measured on a calibrated external power meter. The optical calibration procedure determines optical

transmission characteristics of an intra-beam attenuator optic for Holmium wavelength (Ho & Nd of a dual

wavelength system) and if the laser is a dual wavelength system, the procedure determines the reflectivity

characteristics of the pick-off mirrors for the Neodymium wavelength. Then at each system turn-on cycle, the

software executes an automatic laser calibration (autocal) which allows the computer to determine and store

(in NVRAM) the flashlamp drive parameters required to generate minimum and maximum pulse energies for

each installed laser channel.

NOTE: All Laser Safety procedures must be followed while performing this procedure (i.e., safety

glasses/goggles must be worn).

Blastshield

Alignment Pin

Blastshield

Assembly

Blastshield

Sense Switch

Blastshield

Sense Switch

set screw

FIG. 3.11: BLASTSHIELD SENSE SWITCH

Loading...

Loading...